HDPE Lithium Battery Isolation Film New Energy Case

2020-01-13

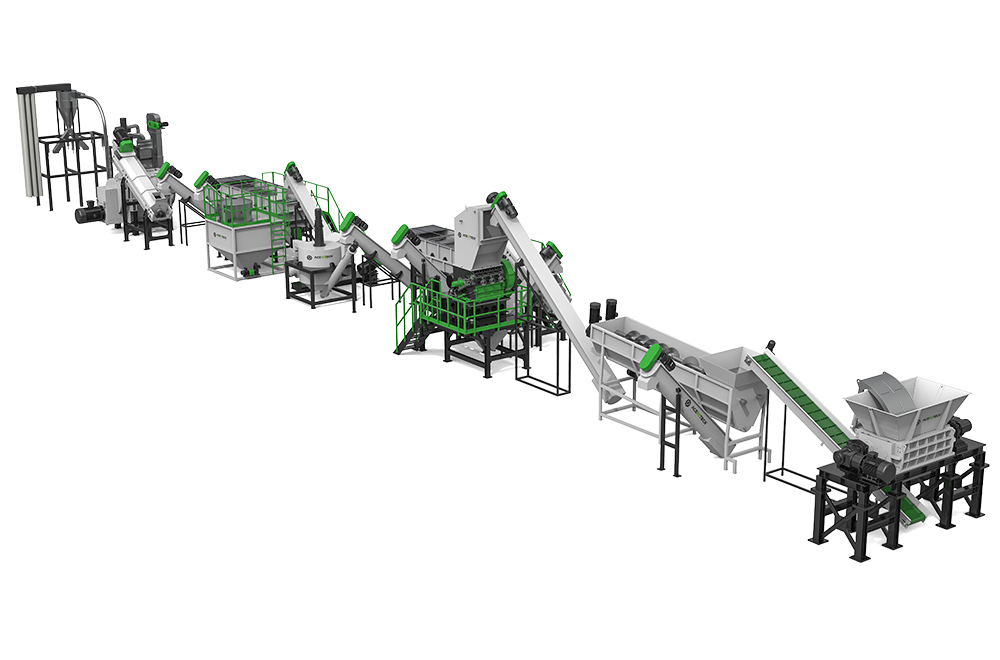

In the field of new energy, ACERETECH has the experience of recycling and granulating lithium battery separators. This kind of raw material is not as simple as other materials, and it belongs to the polymer series. In the production process of lithium battery isolation film, there are many kinds of final thin film products. There is a big difference between oil film and oil-free film in lithium battery film, and even dry film with oil, which cannot be recognized by naked eyes. The thickness of this raw material can reach up to 2mm.

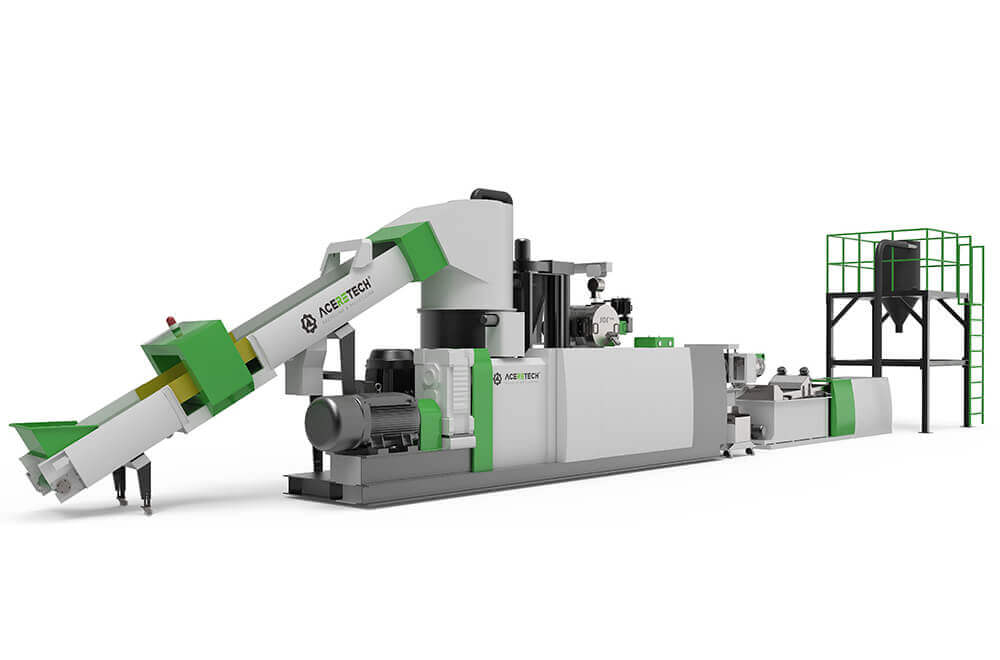

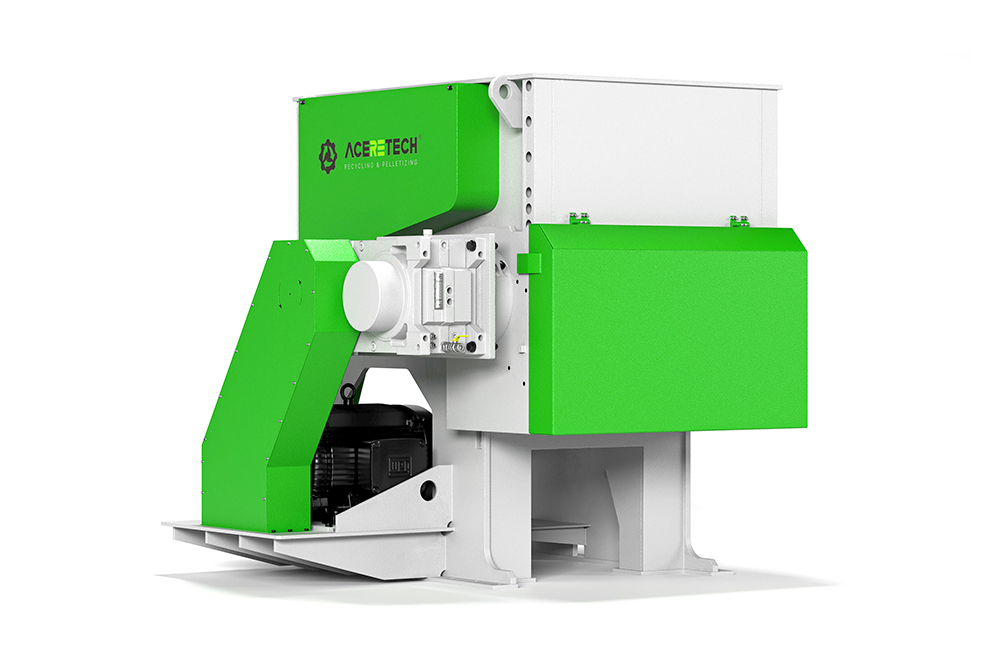

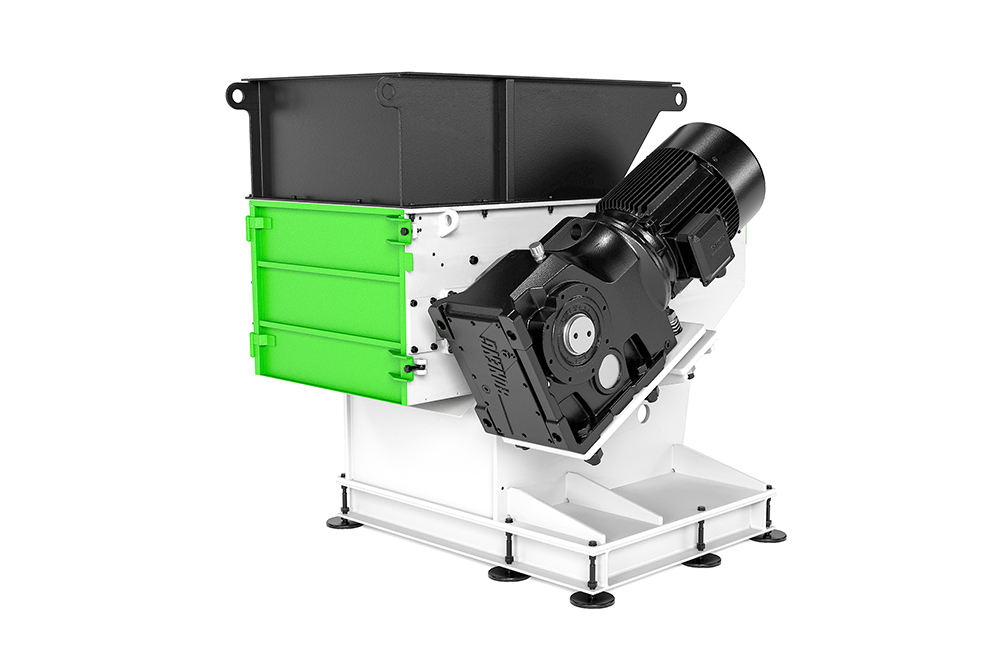

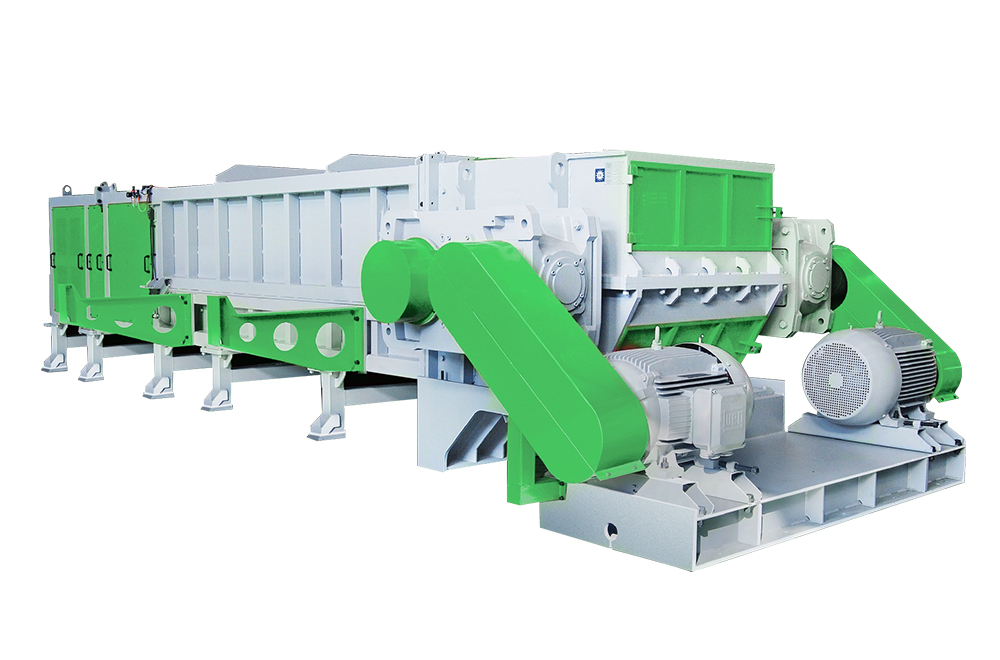

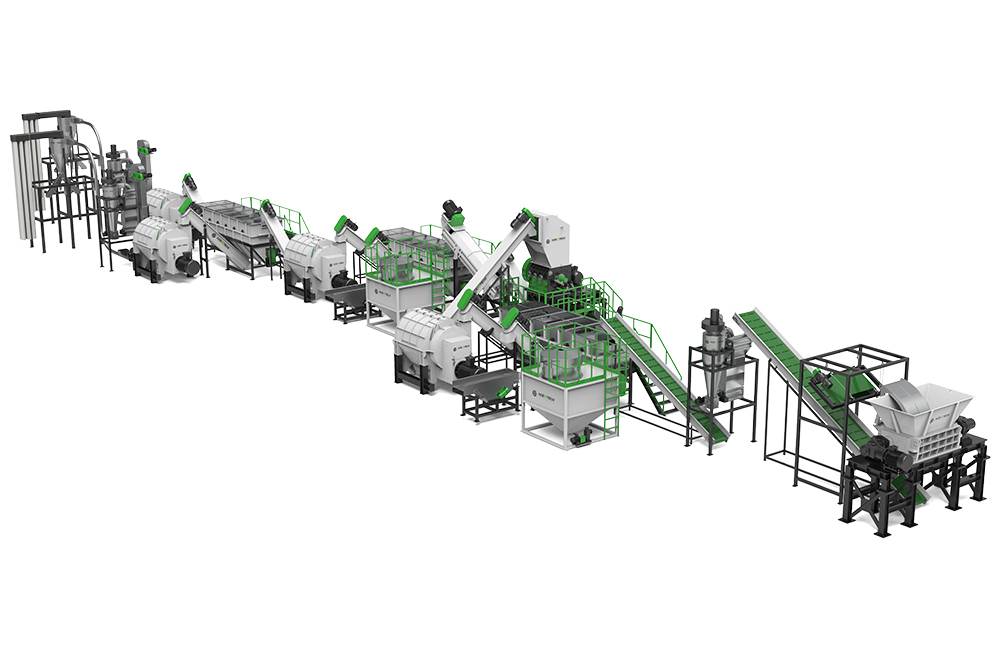

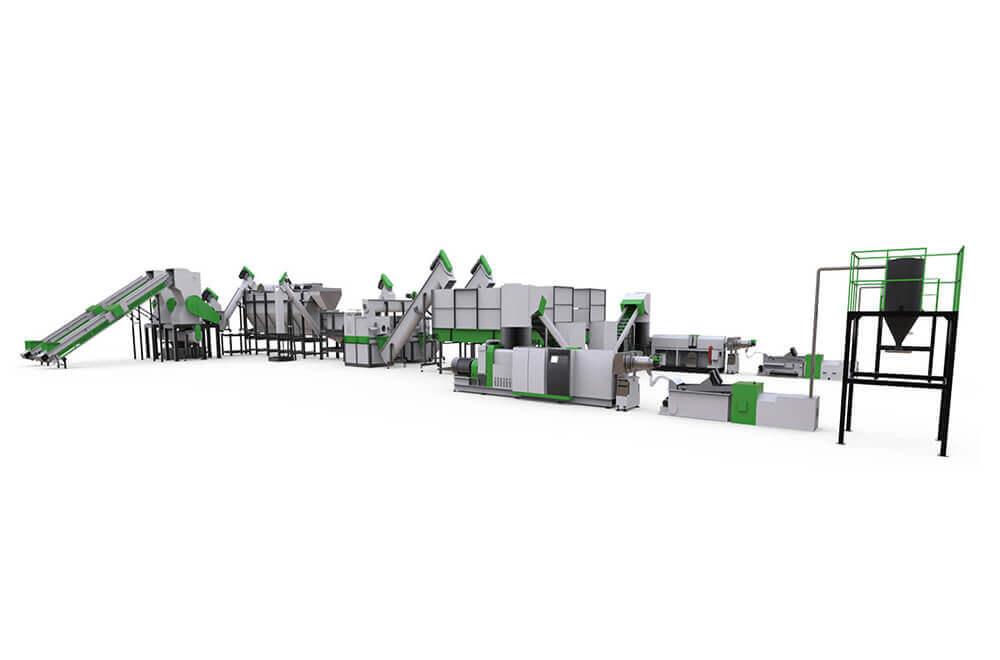

The dry film processing method is integrated with shredding and granulation, coherent processing. Because of the high strength of the polymer film material, it needs to be pretreated first, otherwise the granulator will not only be unable to cut, the extrusion current will also have a great impact, and even stop.

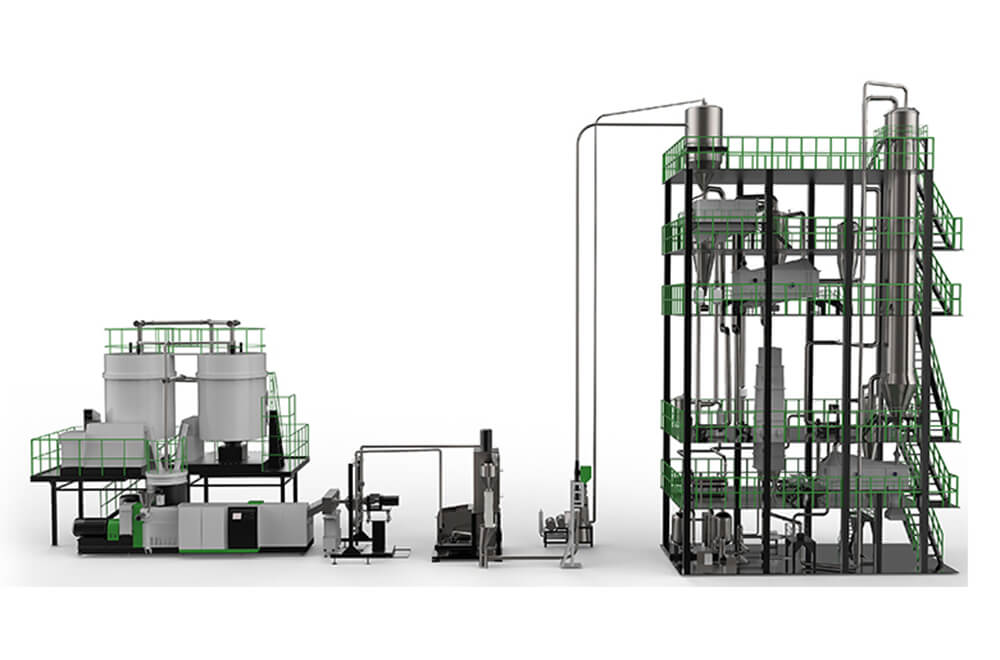

The biggest problem of oil film processing is how to drain oil. As long as the problem of oil connection is solved, granulation is not a problem.

The fluidity of the oil film is better than that of the dry film, which can be clearly reflected in the measured final output.

Raw materials expected to be recycled:

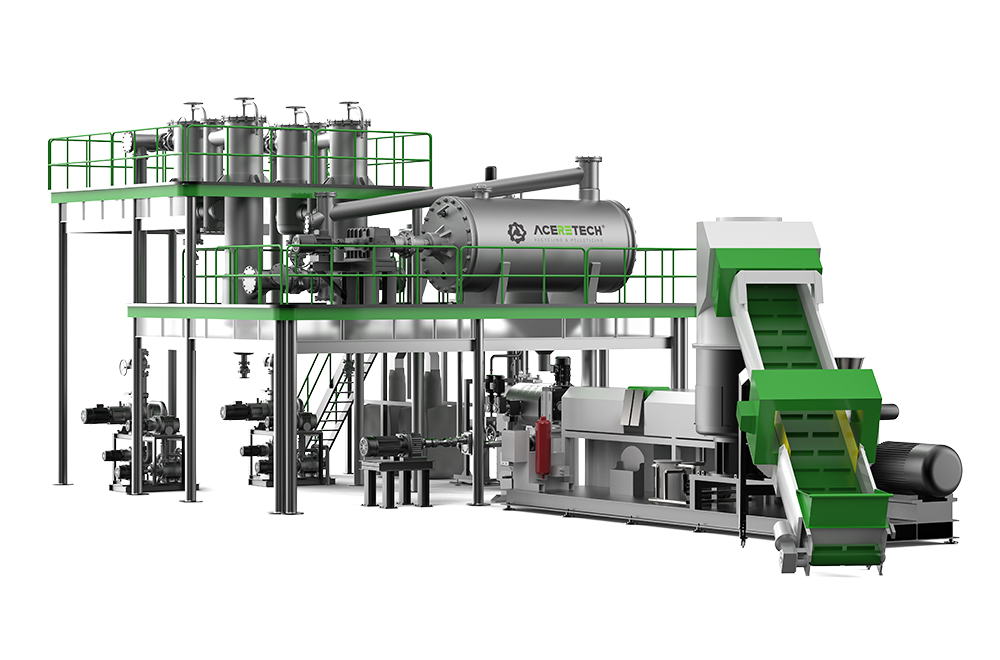

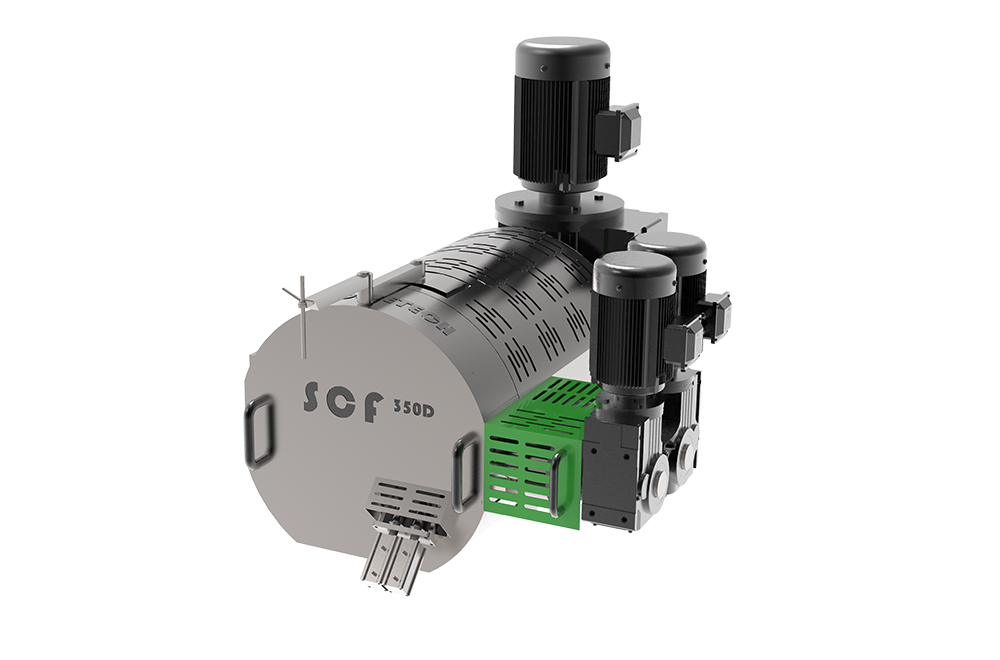

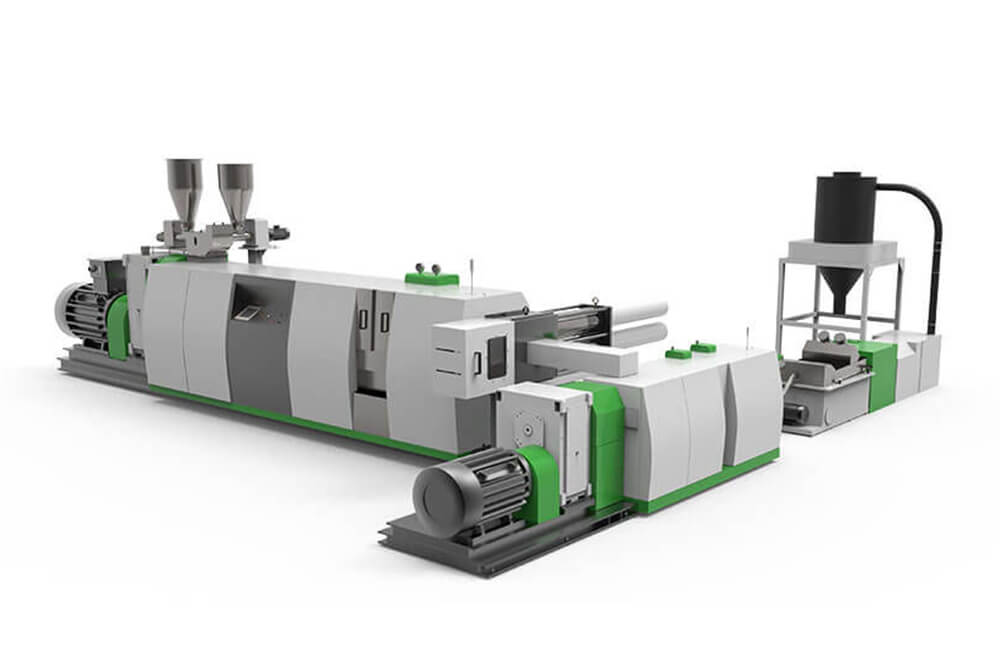

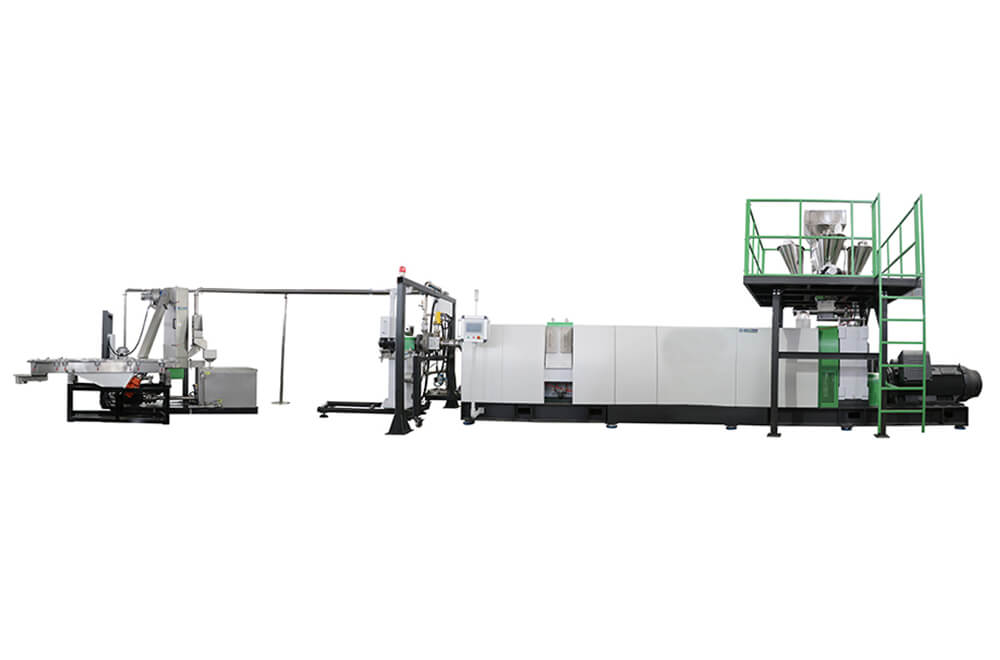

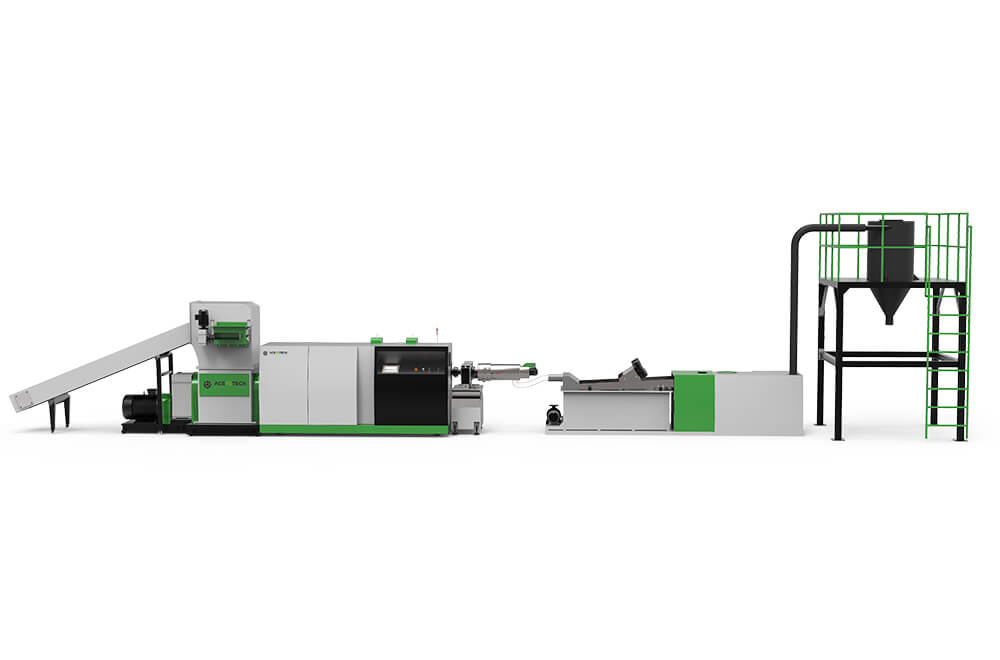

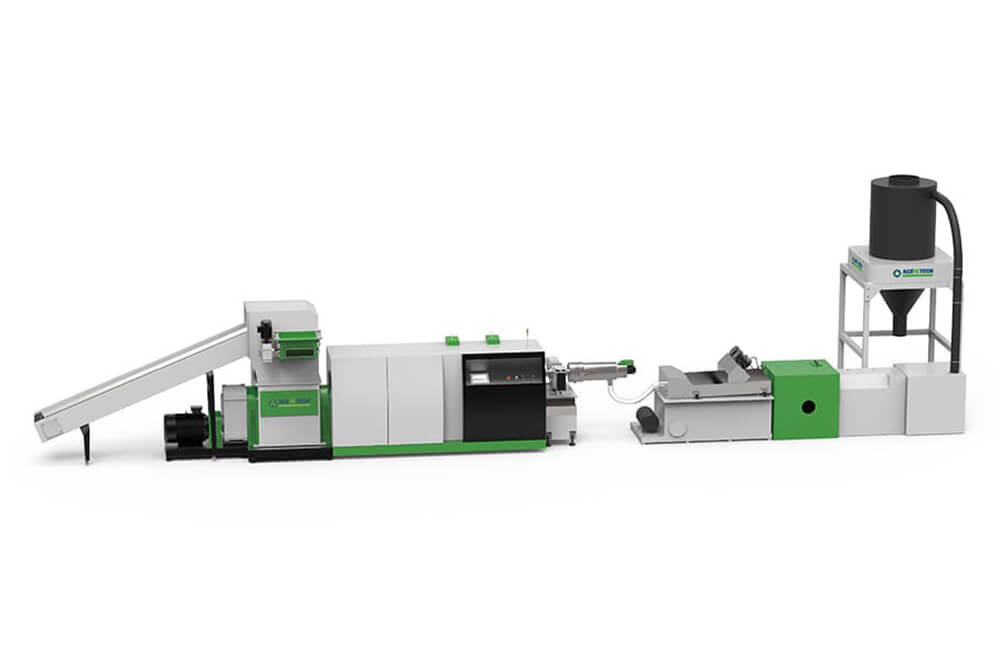

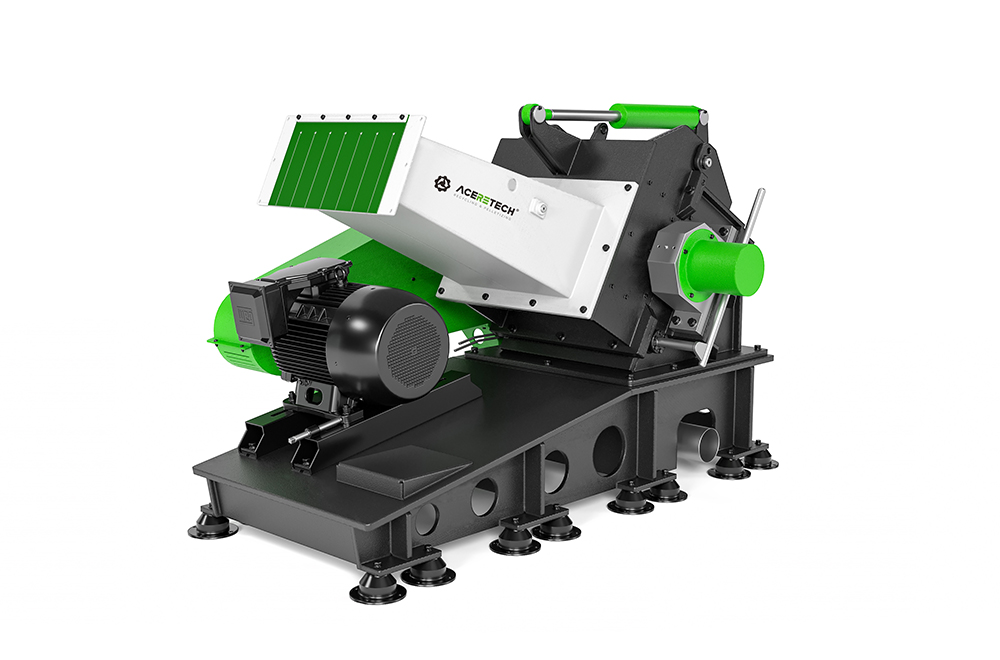

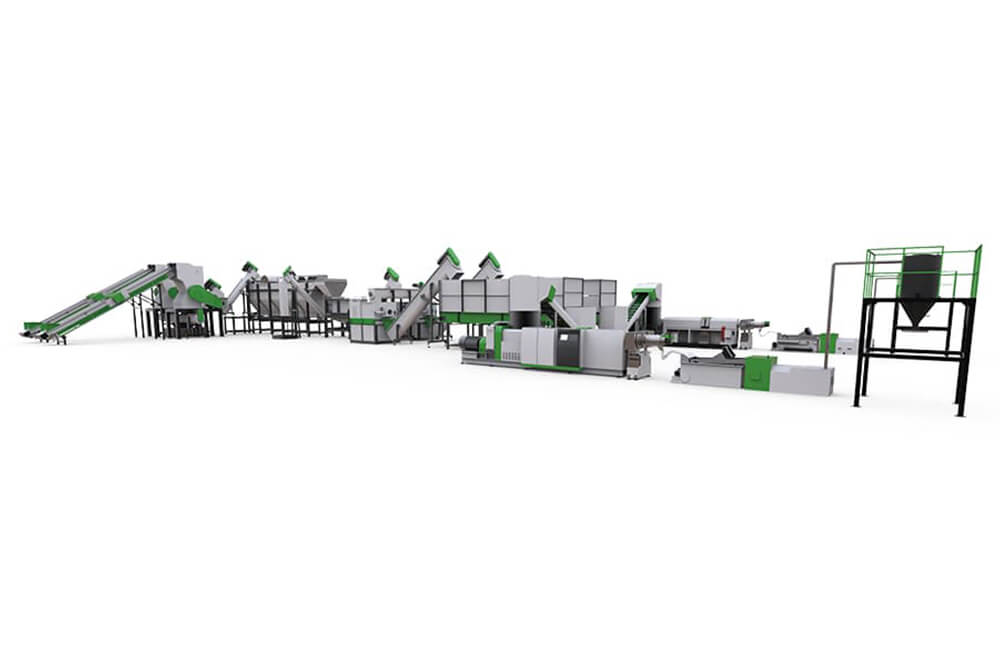

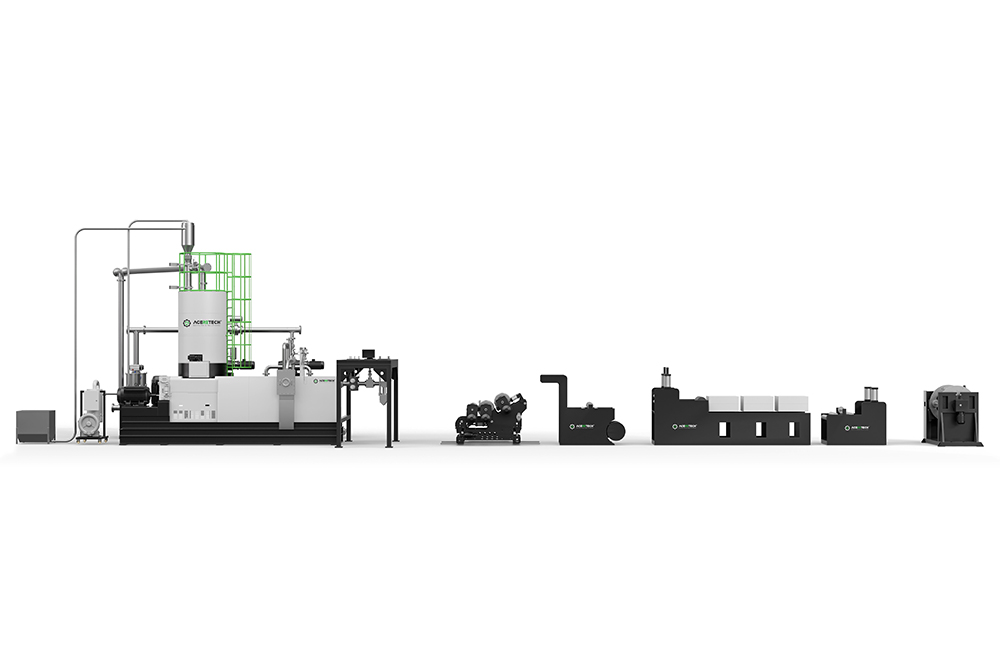

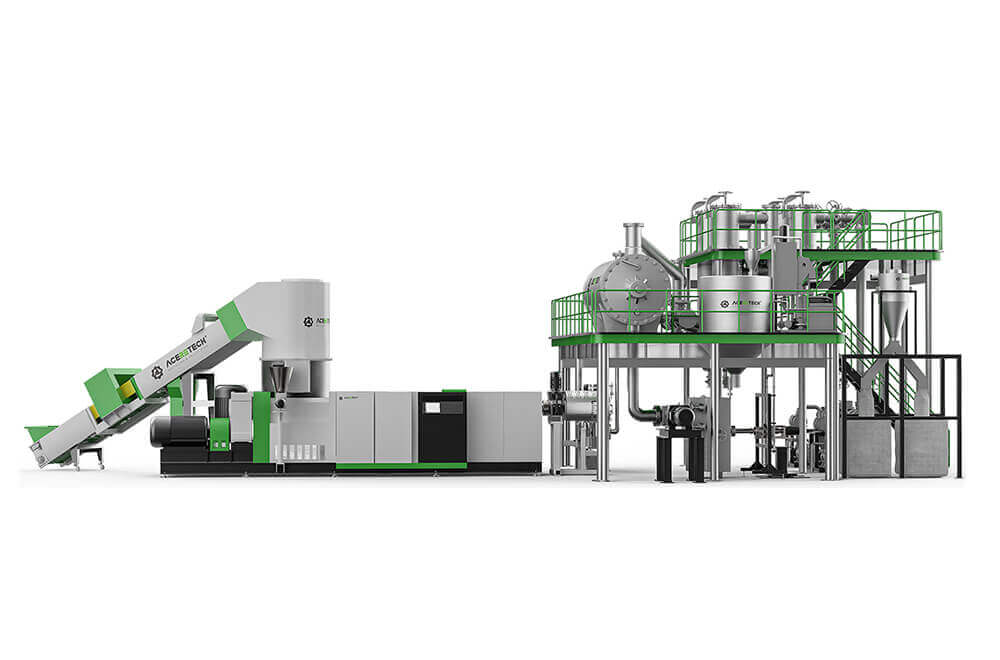

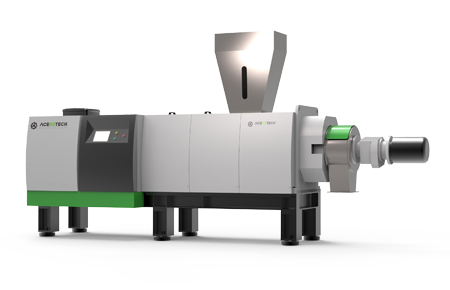

According to the recycling experience of ACERETECH, we recommend the ACS-H compaction granulator for the recycling and granulation of lithium battery film materials.

For more details about the case, please consult your sales staff. We will provide more good advice based on recycling experience to help you.

Raw materials expected to be recycled:

According to the recycling experience of ACERETECH, we recommend the ACS-H compaction granulator for the recycling and granulation of lithium battery film materials.

For more details about the case, please consult your sales staff. We will provide more good advice based on recycling experience to help you.

Application:

Customer area: China

Material: crushed lithium battery film;

Scheme design capacity: 700kg / h;

Actual production capacity: 500-600kg / h dry film

Oil film 950-1000kg / h

With oil film 800-1000kg / h (related to the raw material properties of the output);

Finished product: HDPE particles;

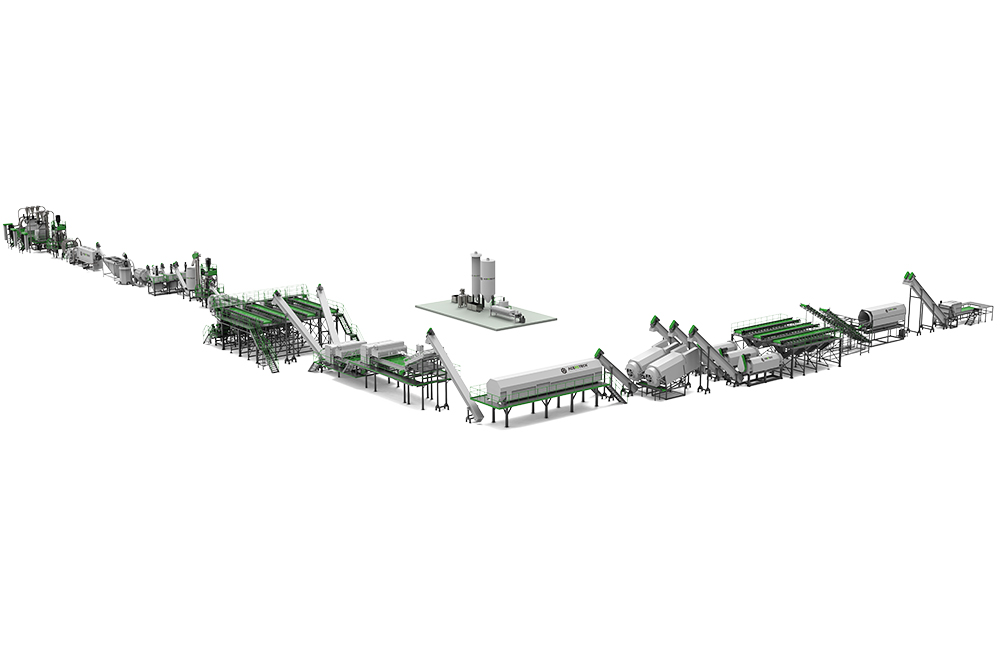

Factory auxiliary configuration: front-end crushing equipment, flue gas collection and processing equipment, chiller.

Customer factory installation:

Customer factory installation:

For more applications please contact ACERETECH Machinery!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us