PE Bags Film

ACERETECH: Revolutionizing PE Bag Film Recycling with Advanced Machinery

PET bag films are plastic materials that are widely used for packaging and storing various products. However, they also pose a serious threat to the environment, as they are non-biodegradable and consume a lot of energy and resources to produce. Recycling PET bag films can help reduce plastic waste, save landfill space, conserve natural resources, and lower greenhouse gas emissions. Recycling PET bag films is a responsible and sustainable way to protect our planet.

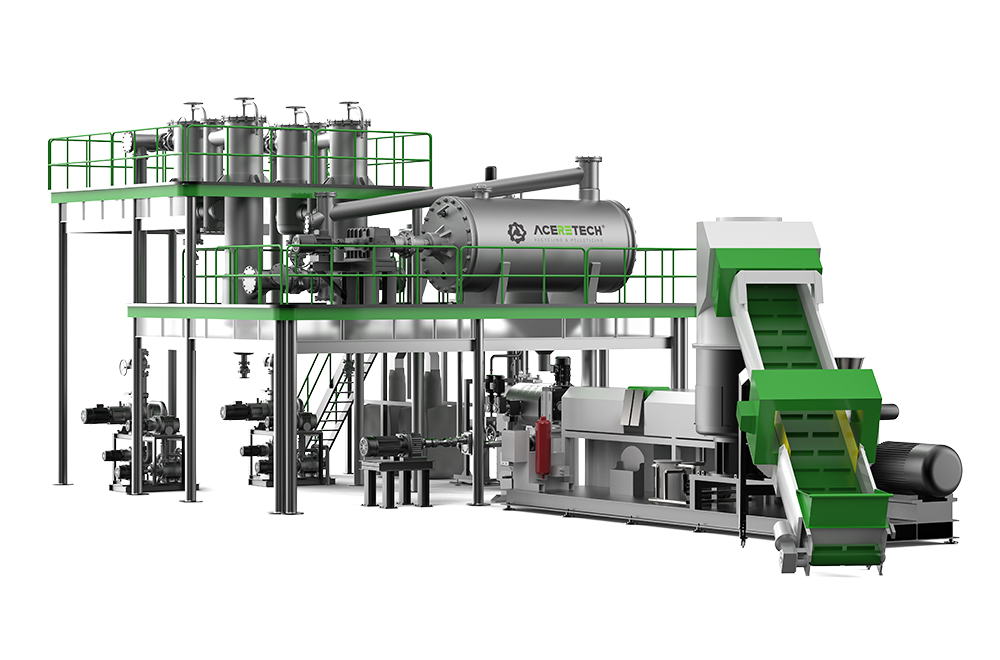

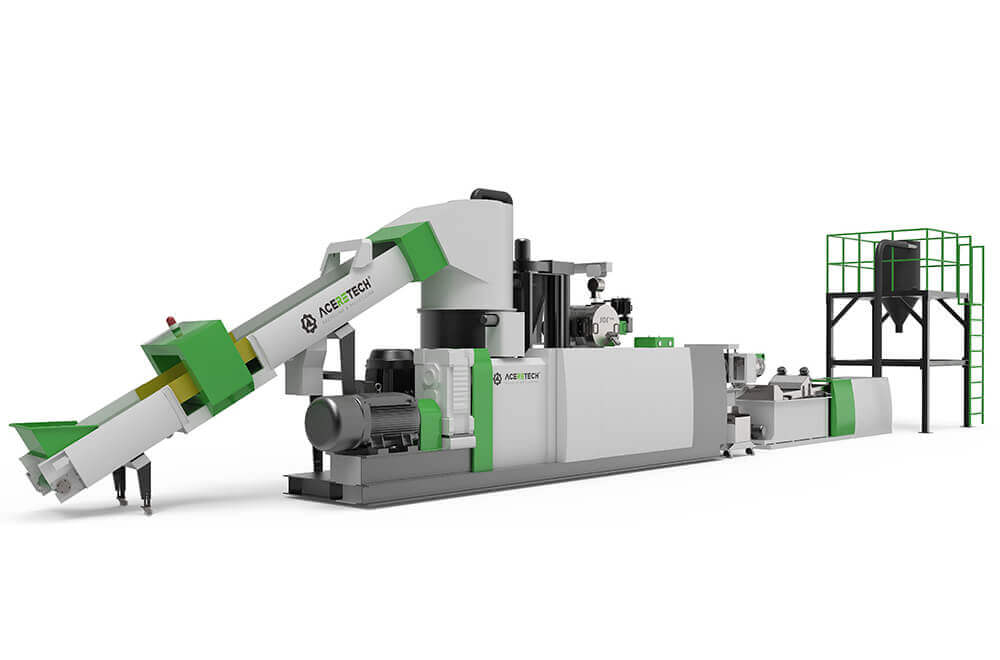

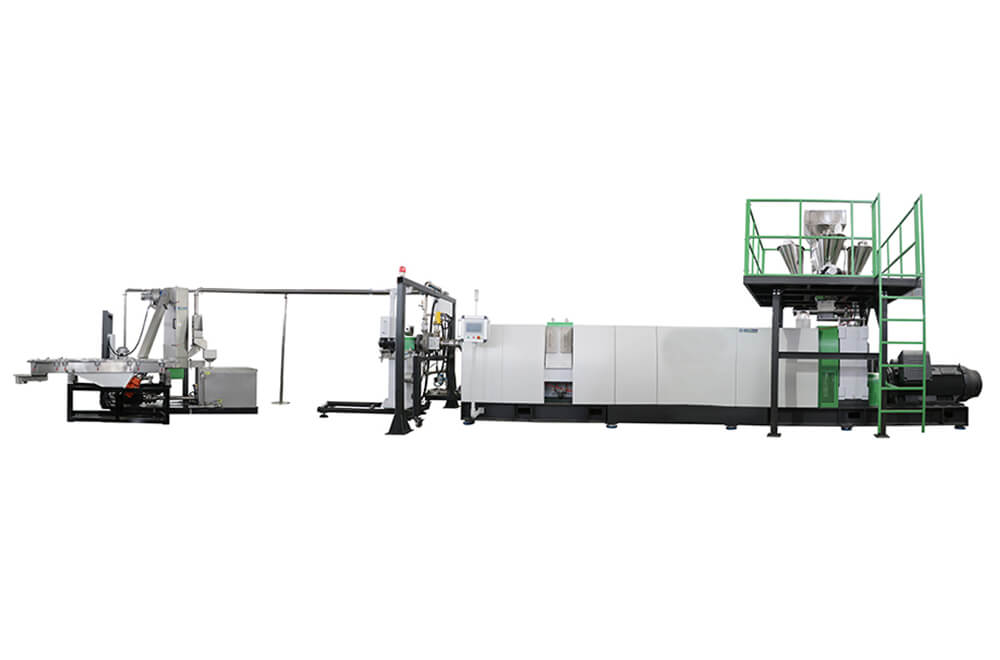

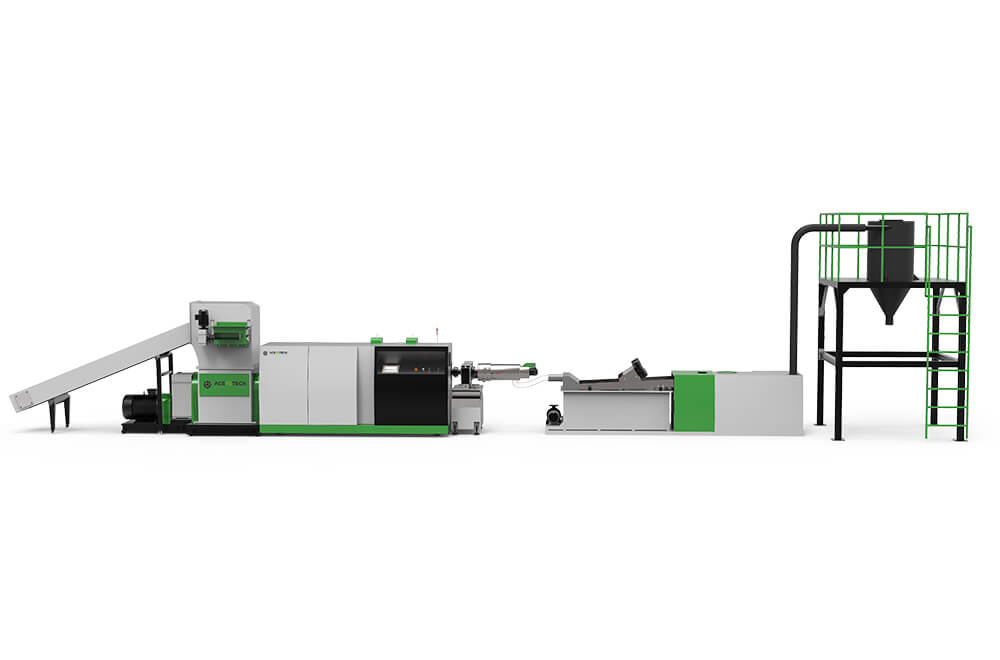

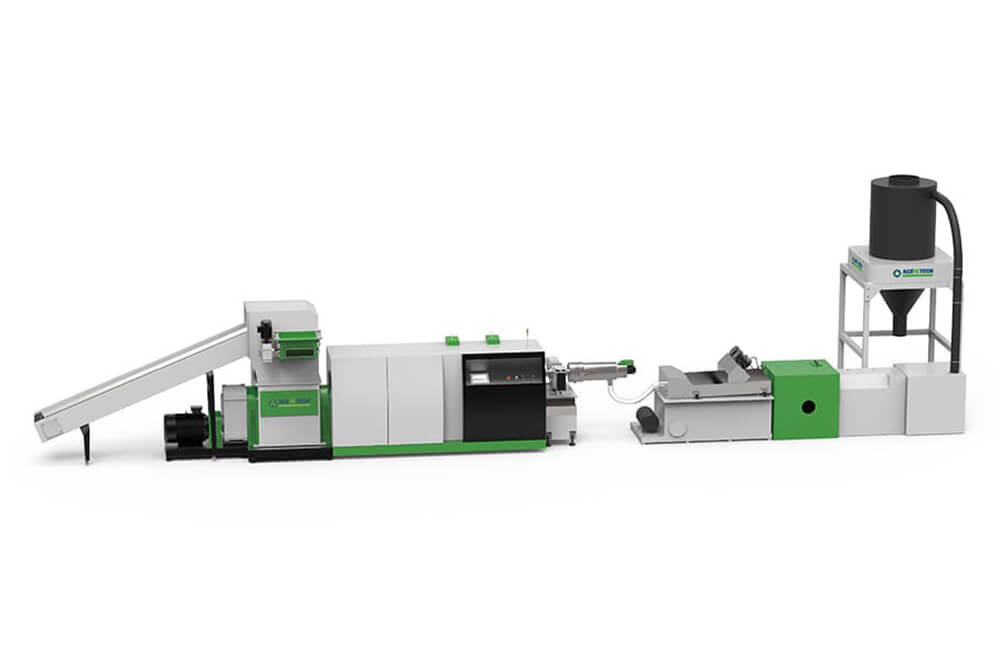

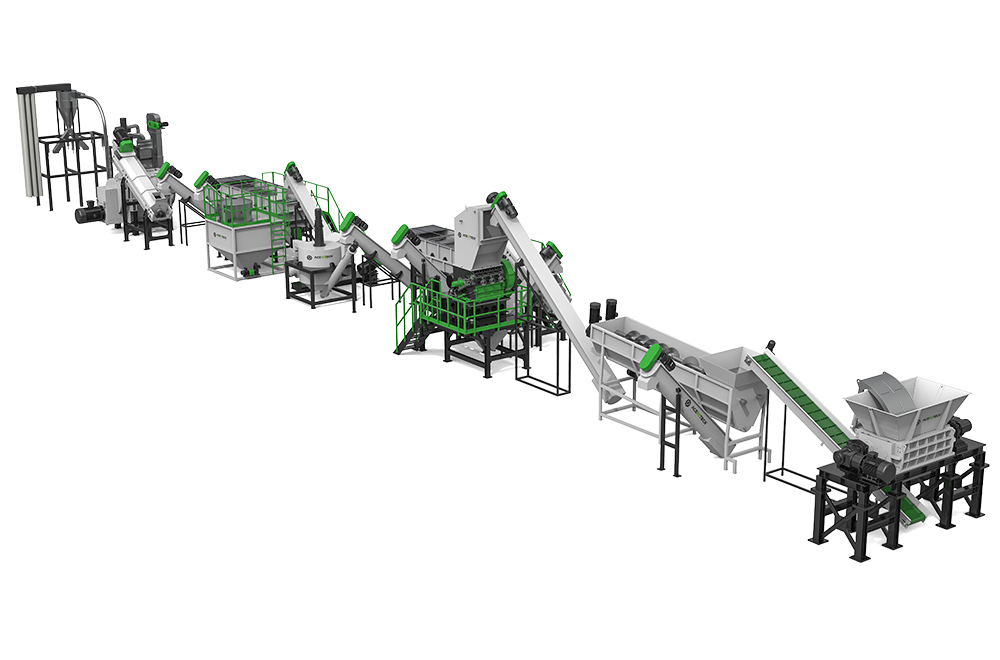

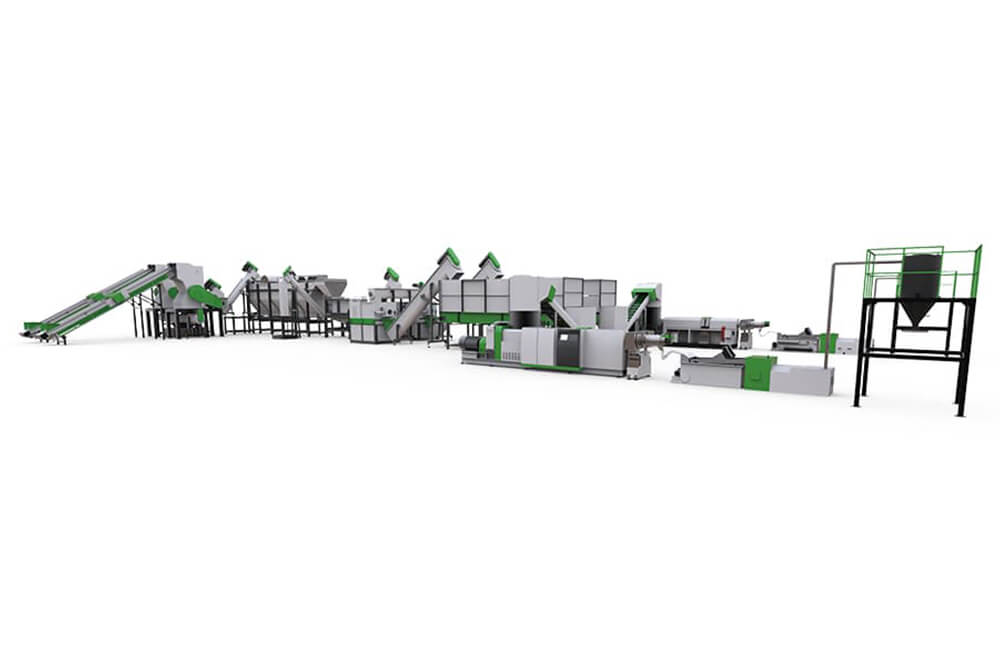

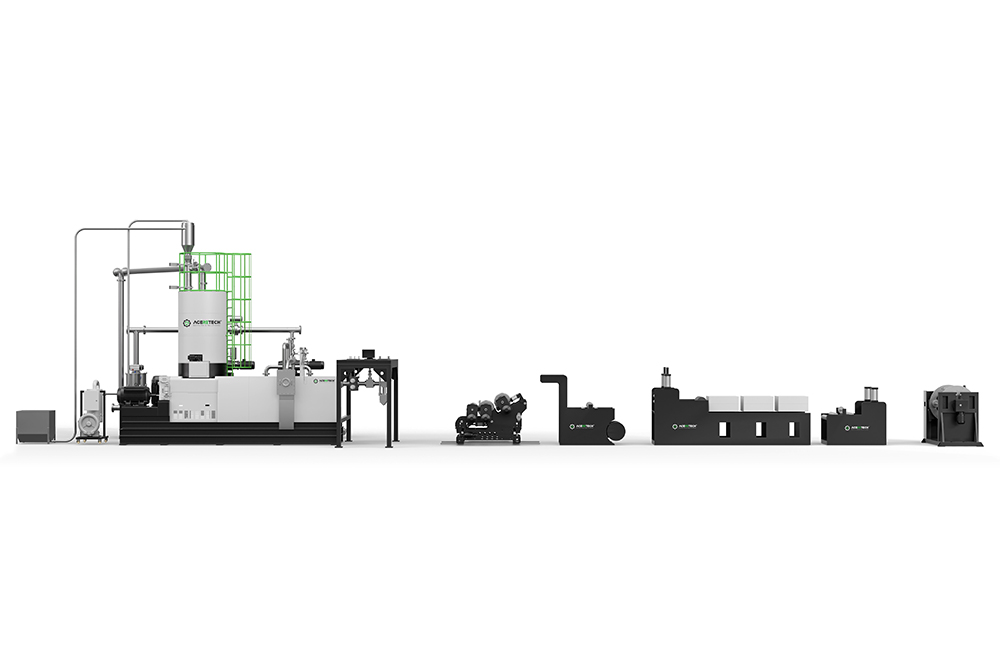

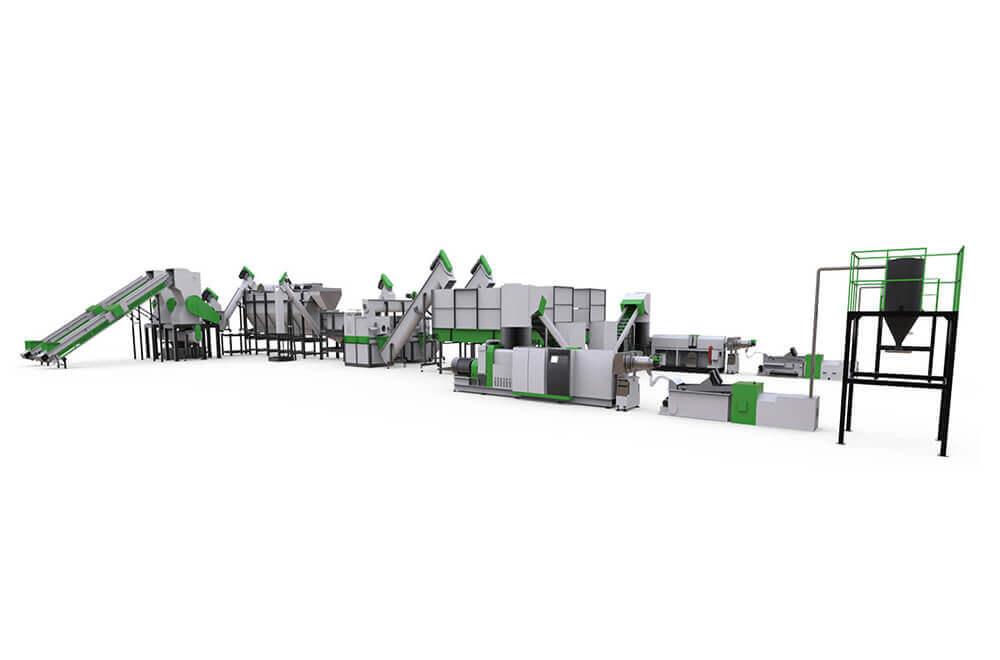

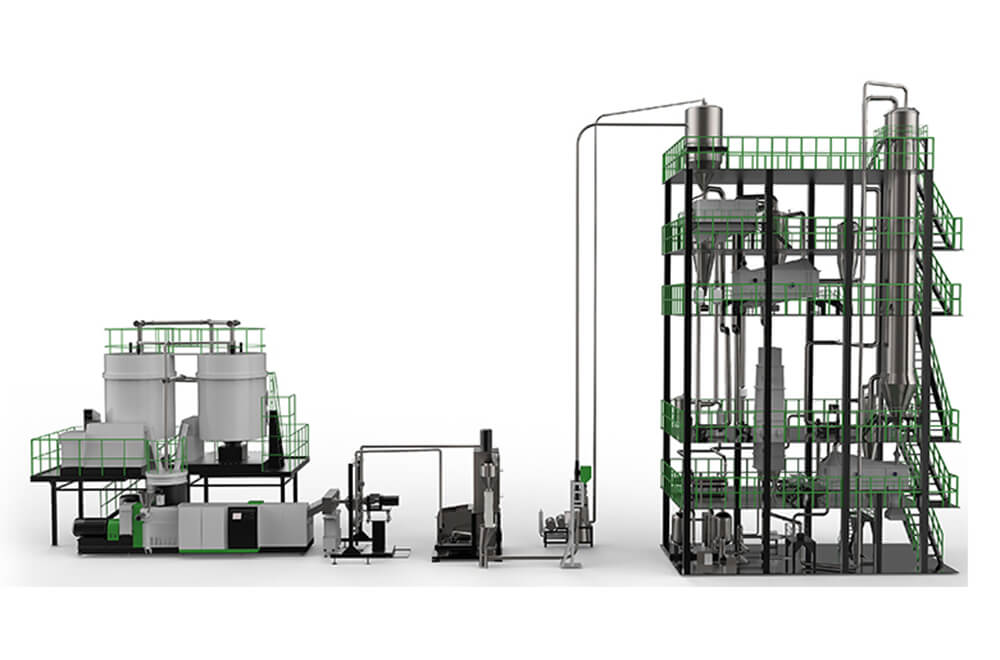

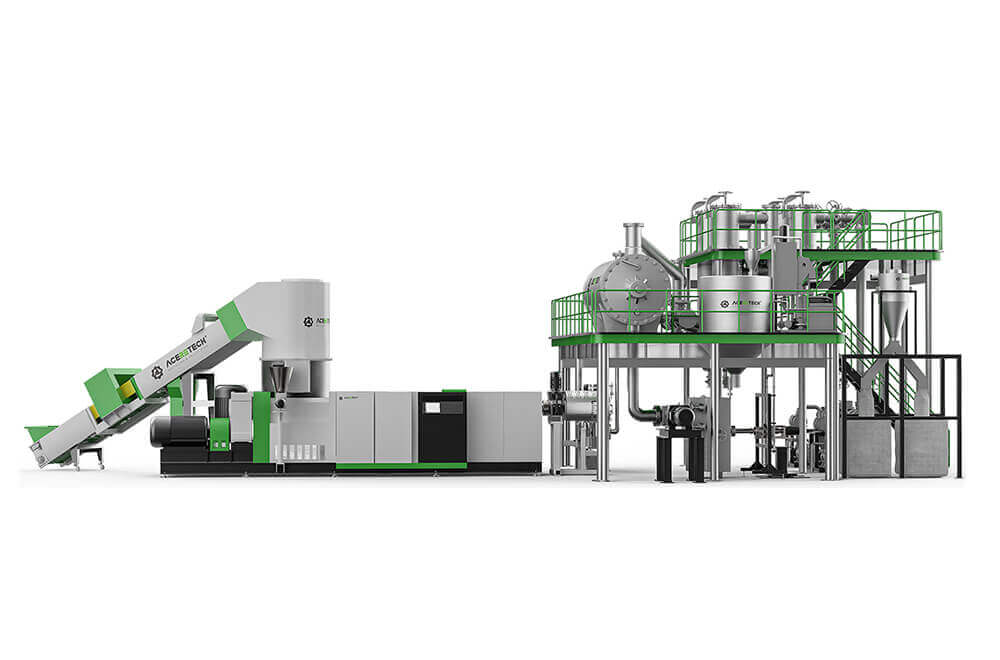

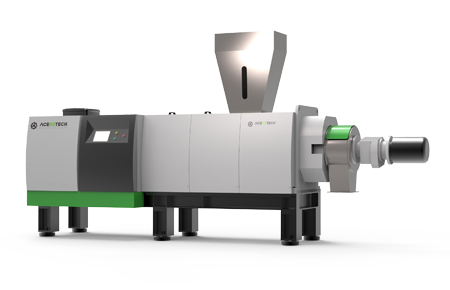

ACERETECH, a leading name in the plastic recycling machinery sector in China, proudly presents its innovative solution for recycling PE bag films. Our state-of-the-art machinery, the ACS800/120 Compacting and Single Screw Extruder equipped with an Automatic Strands Pelletizing System, is designed to transform crushed PET fiber/cloth into valuable recycled materials. This system is currently operational in the Czech Republic, showcasing its efficiency and reliability.

Machine Workflow:

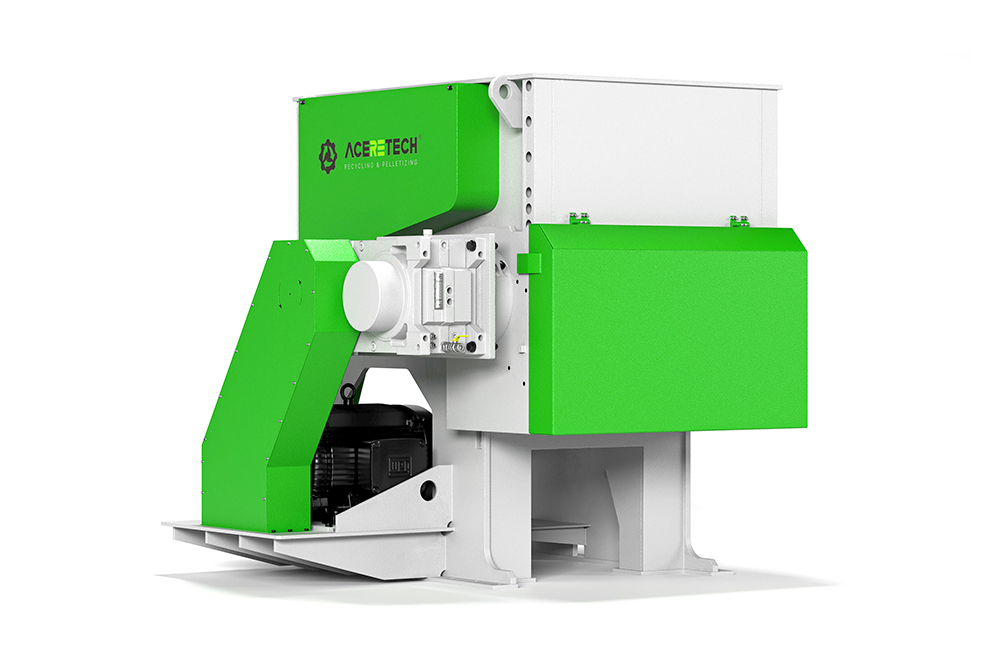

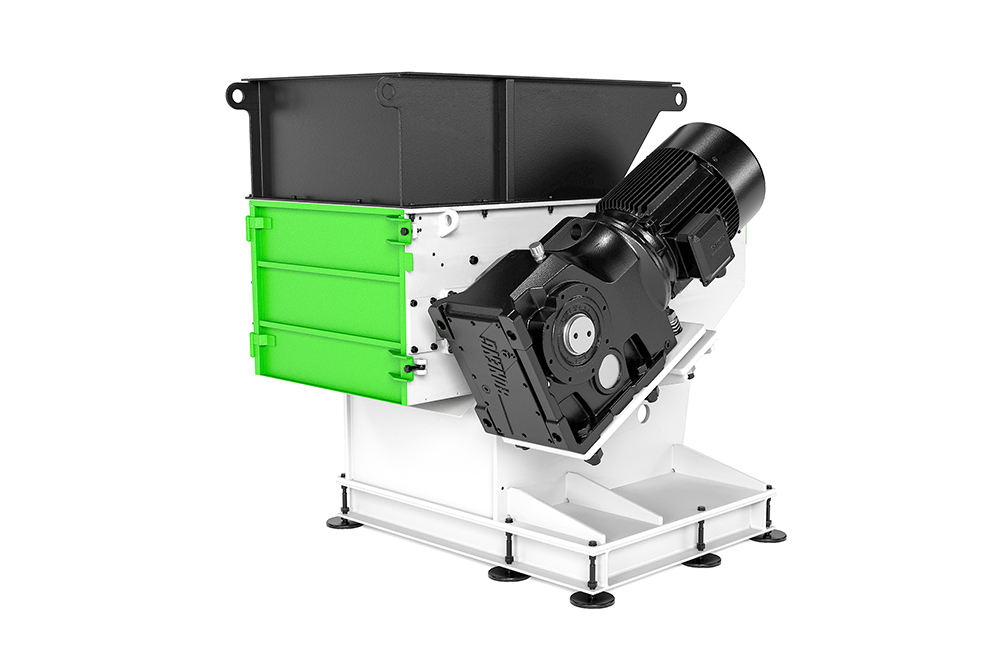

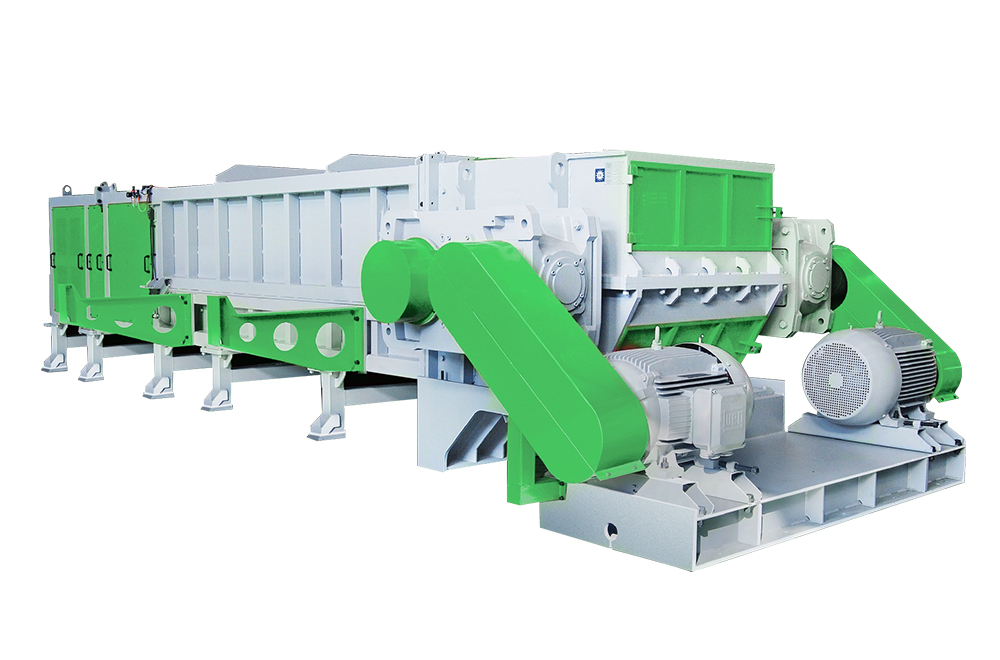

- Crushing: Initiates the recycling process by downsizing PE bags/films, facilitating easy feeding into the pelletizing machinery. This step significantly reduces compactor pressure and enhances overall throughput.

- Belt Feeding: Incorporates an edge-sealing feature to ensure the efficient transfer of materials, preventing spillage.

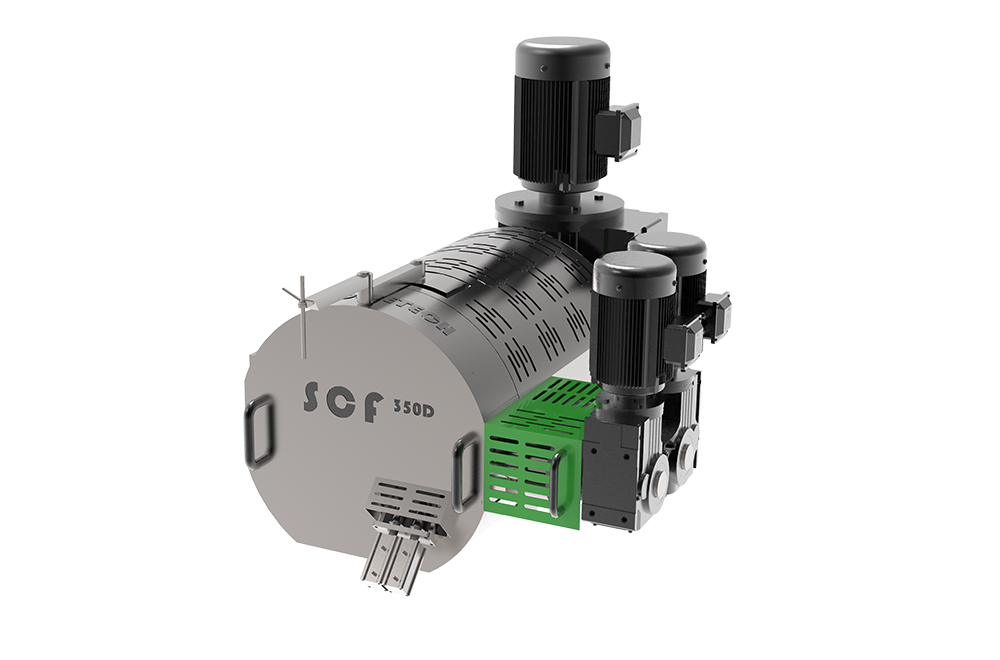

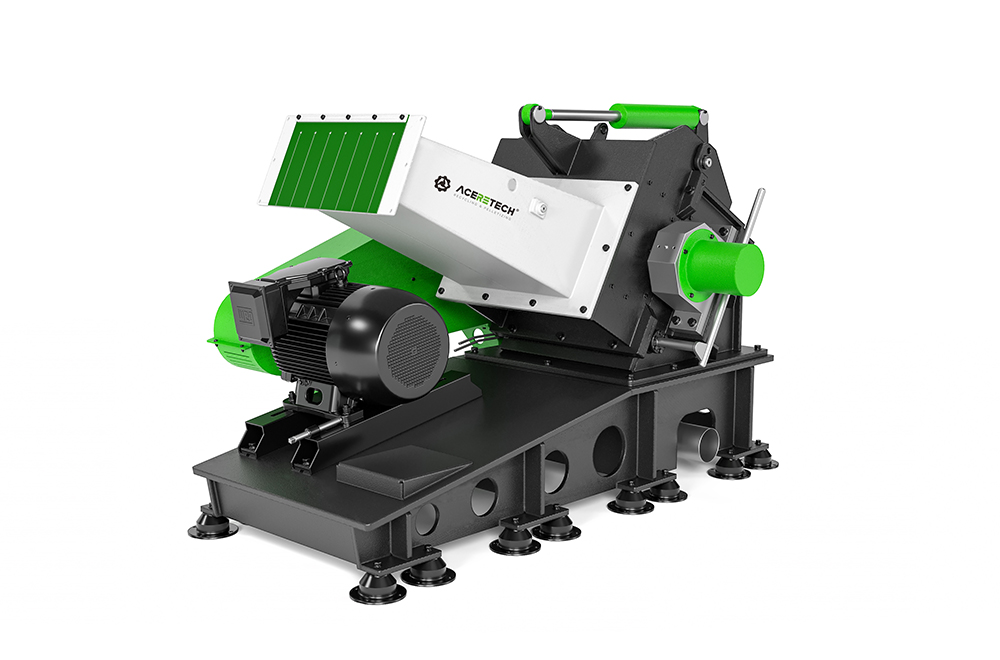

- Compacting: Utilizes both rotary and stationary blades for material preheating and cutting, featuring a unique guide groove for seamless feeding into the extruder.

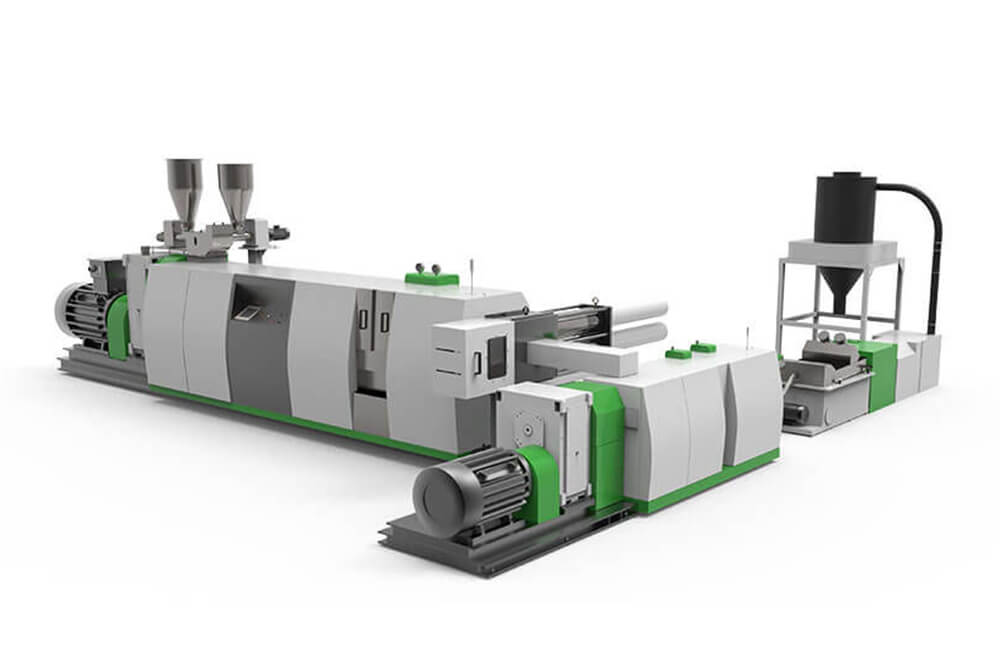

- Extruding: Adapts to various materials with its diverse screw structure designs.

- Vacuum Pumping: Extracts residual ink and impurities, ensuring the purity of the recycled product.

- Screen Changing: Offers an extensive filtration area for continuous operation.

- Water-ring Pelletizing: Employs pneumatically adjusted cutting blades for precise pellet formation.

- Vibration Drying: Conducts initial water removal and sieves pellets to specification.

- Centrifugal Drying: Eliminates surface moisture from pellets, preparing them for the market.

ACERETECH's commitment to innovation and quality makes us a preferred partner in Waste PET Recycling Machines for bottles, film, woven bags, etc. For more details on how our machinery can benefit your recycling efforts, feel free to contact our service team!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us