Recycling Methods of Waste Plastics

♻️ Methods of Recycling Waste Plastics

Landfills and incineration have been used to treat waste plastics, although they have played a certain role. However, in recent years, the problem of waste resourceization has gained worldwide attention, and how to turn hazardous waste (waste plastics) into effective resources has become a popular research topic in the international arena. The use of landfill, incineration of these two treatment methods will cause a certain waste of resources, so people have developed a new recycling technology of waste plastics, in order to really make the best use of all the capacity and value of the use of plastic.

Article Paragraph Contents

Ⅰ. The direct use of waste plastics

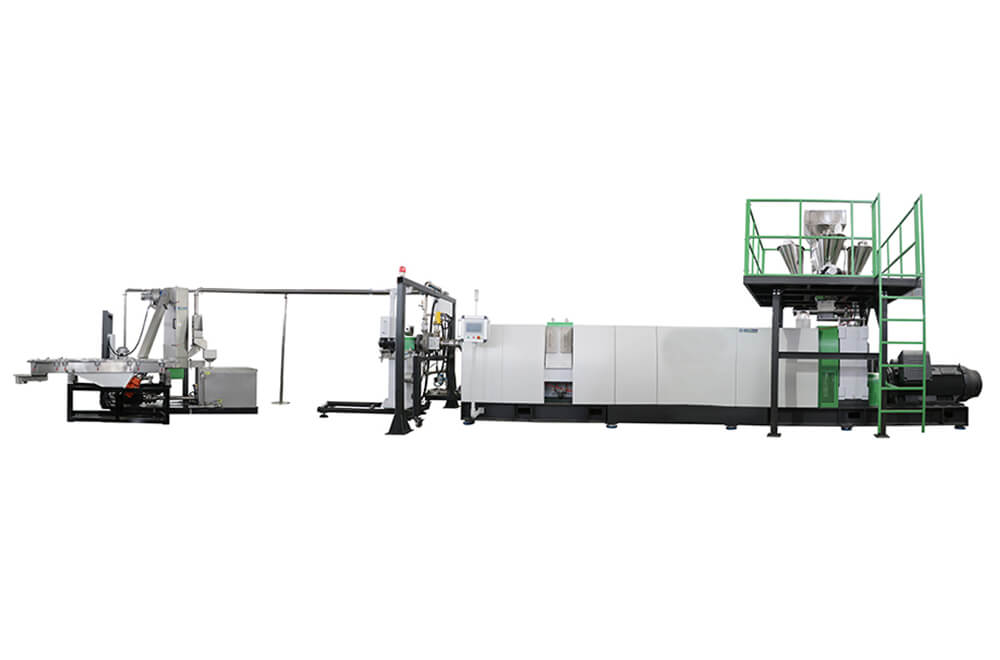

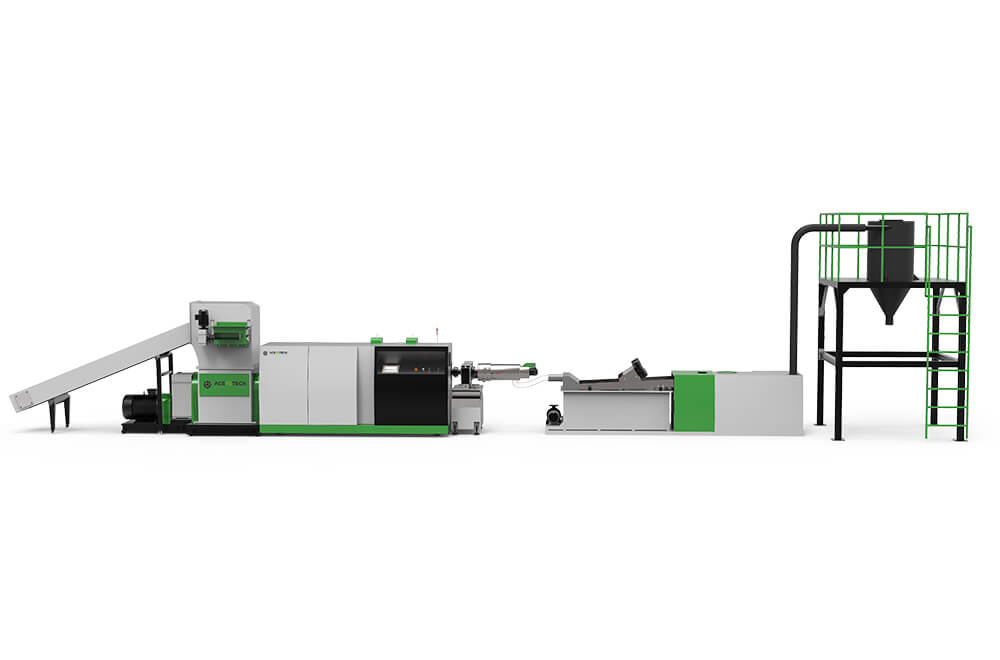

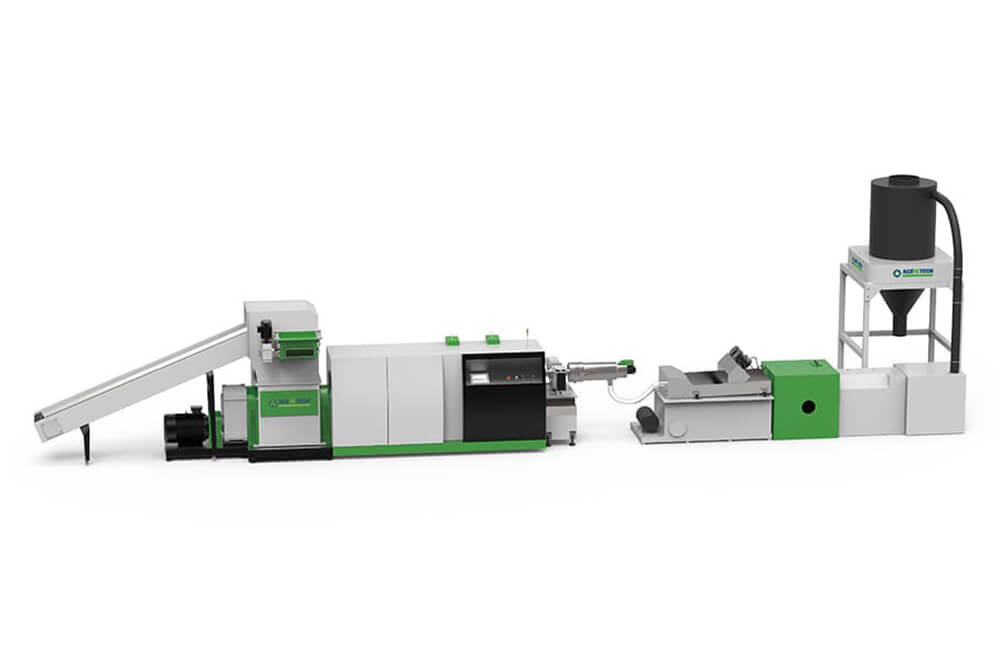

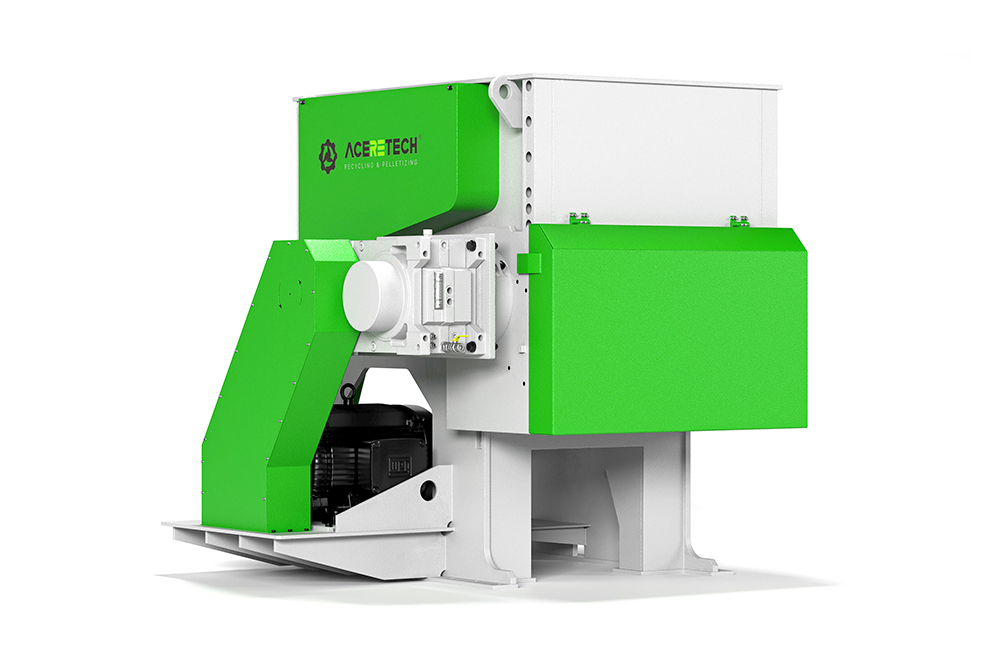

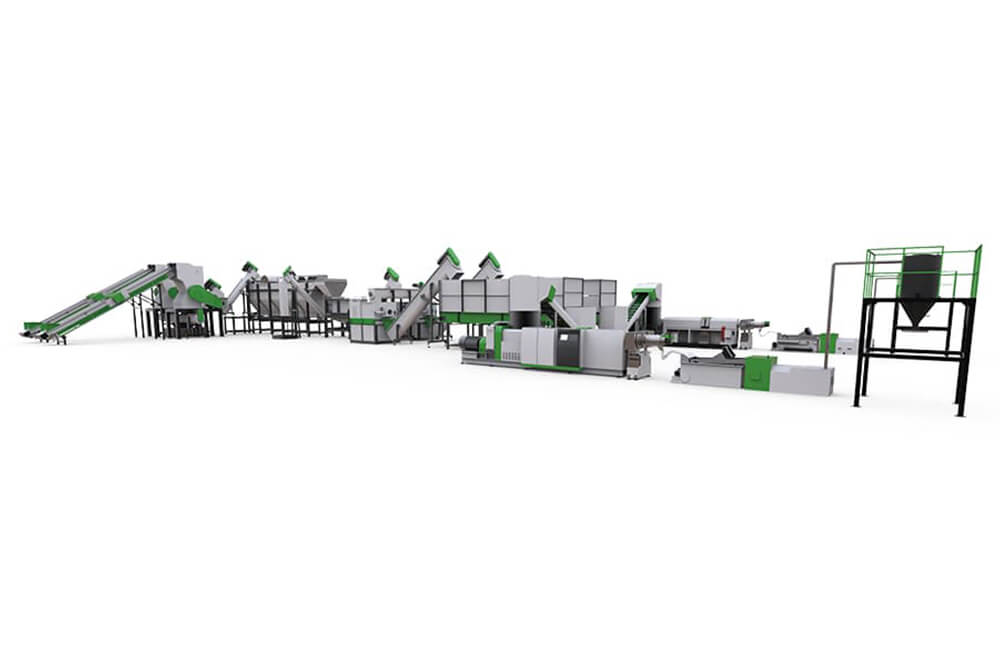

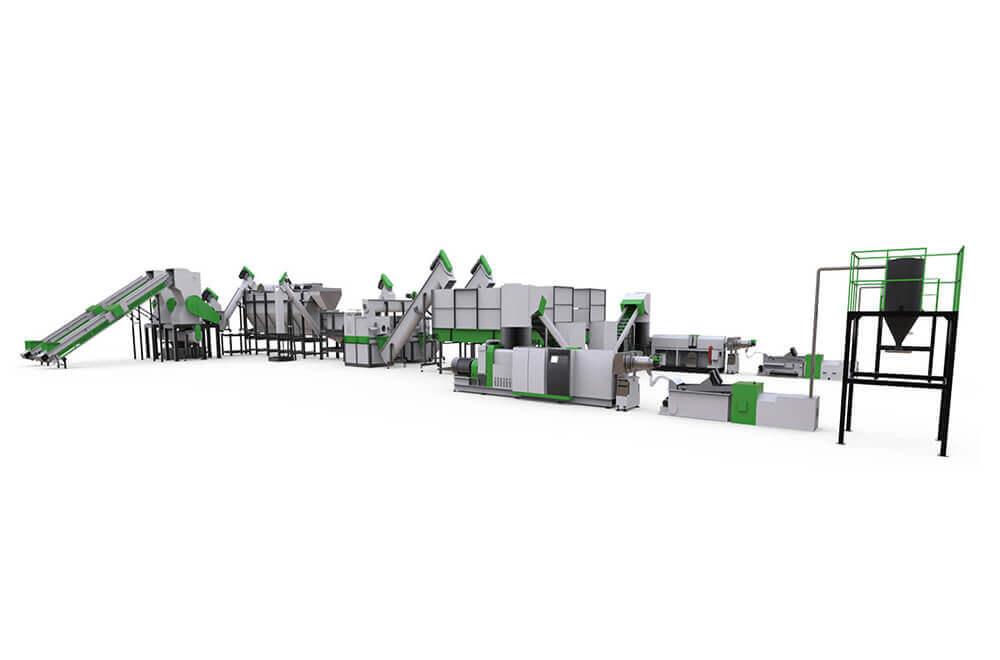

The direct use of waste plastics refers to the waste plastics without all kinds of modification, after cleaning, crushing, compaction granulation, extrusion, direct processing and molding, or with other materials by simple processing into useful products. A lot of research has been conducted on this technology at home and abroad, and the products have been widely used in agriculture, fishery, construction, industry and daily necessities. For example, the waste hard polyurethane foam is finely ground and added to the hand-made clean paste, which can be made into abrasive; the waste thermosetting plastic is crushed and ground into fine material, and then mixed into the new resin with a ratio of 15% and 30% as filler, the physical and chemical properties of the resulting products do not change significantly; the waste soft polyurethane foam is broken into pieces of the required size, which can be used as a cushioning filler and carpet lining material for packaging; rough and The rough, finely ground leather plastic bonded with polyurethane adhesive can be continuously processed into plates; waste plastics crushed and granulated can be used as raw materials for iron making to replace the traditional coke, which can significantly reduce the emission of carbon dioxide.

Ⅱ. The modified use of waste plastics

The main advantage of direct recycling of waste plastics is the simplicity of the process. The cost of recycled products is low, the disadvantage is that the mechanical properties of recycled material products decline, not suitable for the production of high-grade products. In order to improve the basic mechanical properties of recycled waste plastics and meet the quality requirements of special products, researchers have adopted various modification methods to modify waste plastics to meet or exceed the performance of the original plastic products.

The phenomenon of "white pollution" caused by waste plastics is getting more and more attention, while people are committed to solve the "white pollution", more attention should be paid to the research of comprehensive utilization technology of waste plastics, according to the "reduction, harmless, resource According to the principle of "reduction, harmlessness and resource utilization", we can recycle resources and turn waste into treasure to achieve the unity of economic, environmental and social benefits.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us