Analysis Of The Working Principle And Characteristics Of The Single-Shaft Shredder

2022-10-28

Article Paragraph

Ⅰ Overview

Ⅱ Analysis of working principle

Ⅲ Equipment Features

Overview

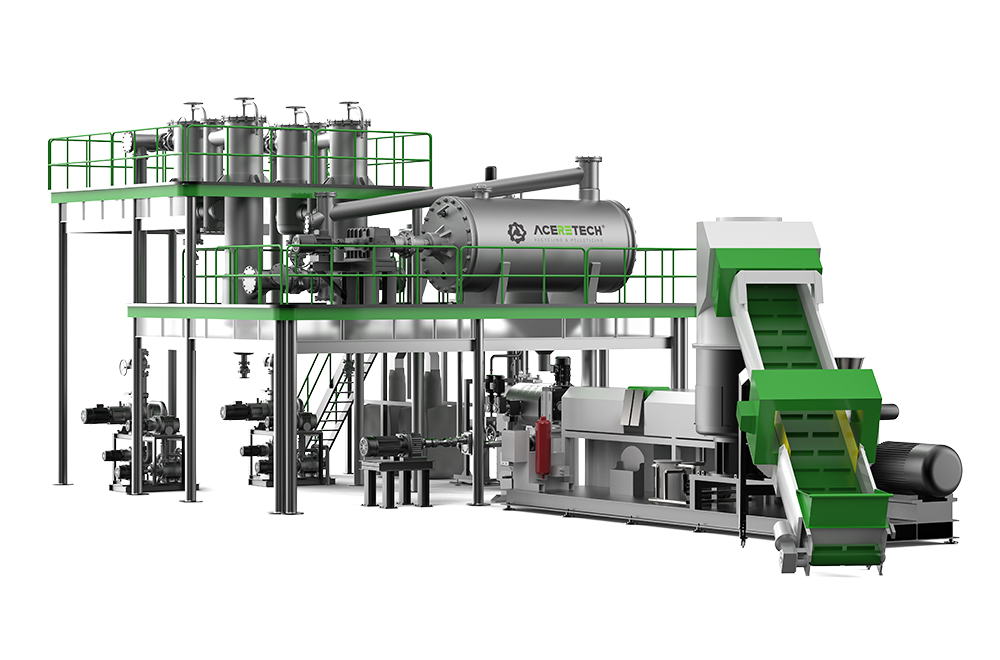

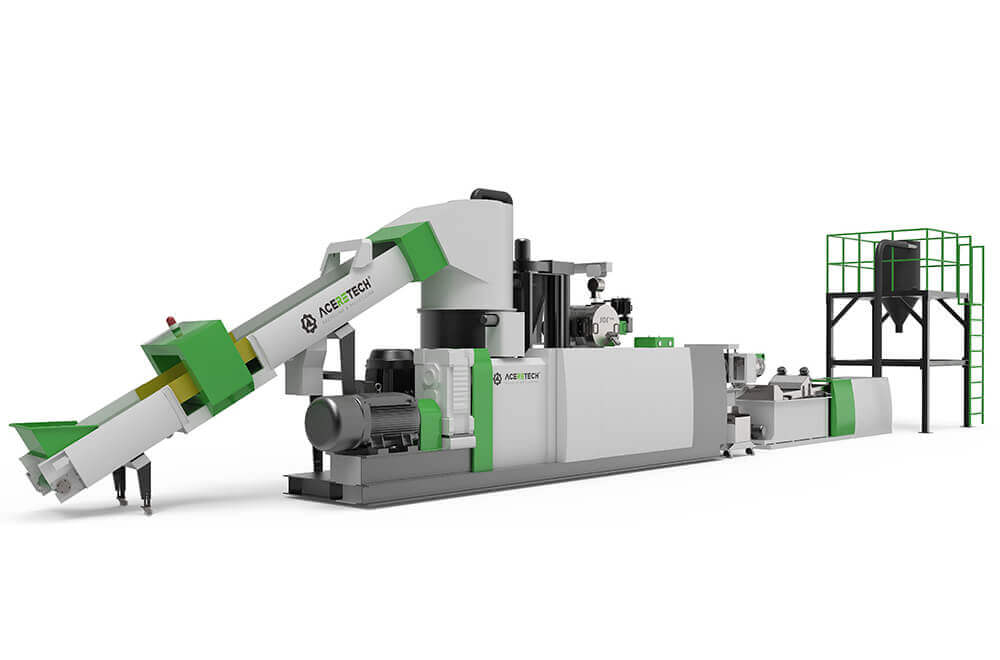

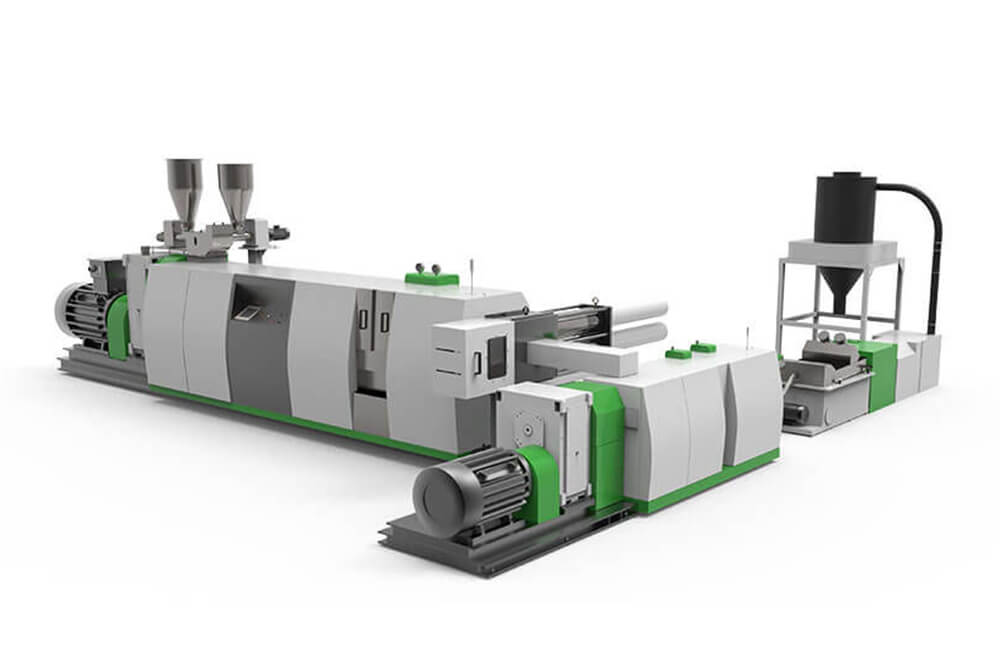

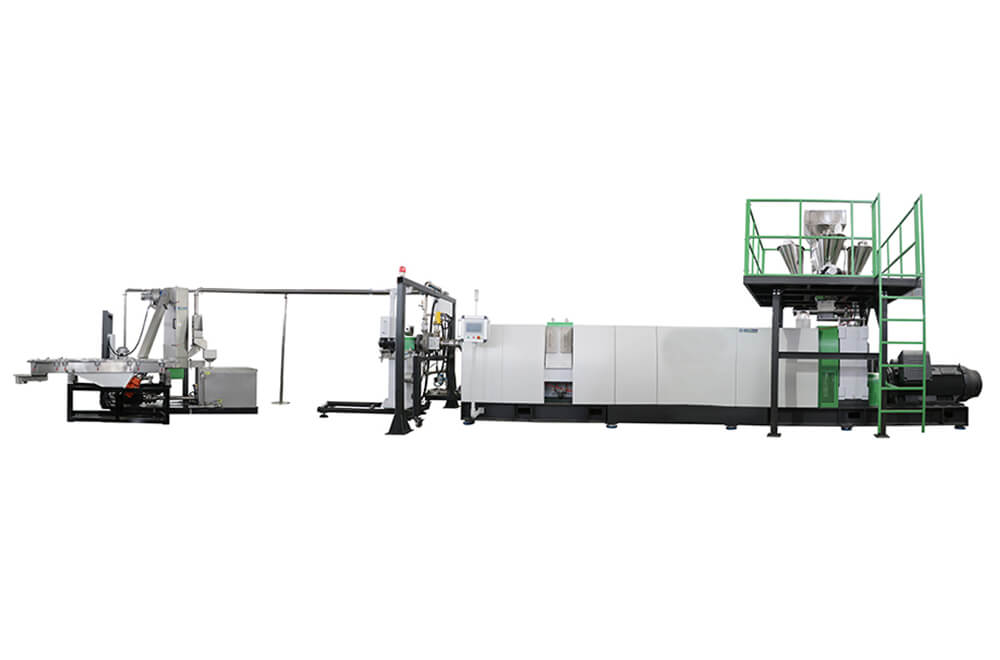

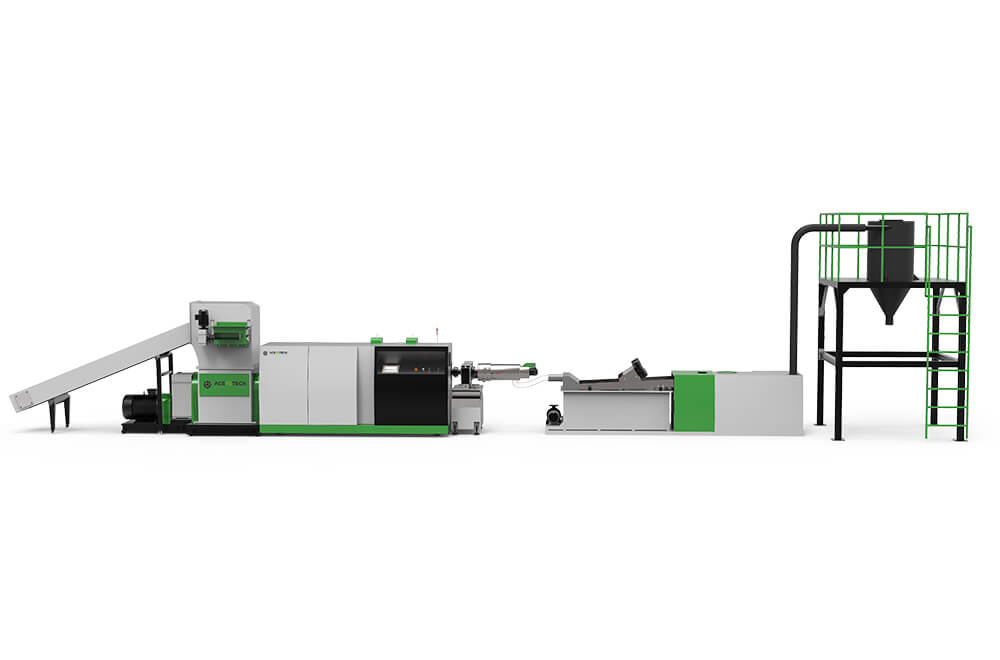

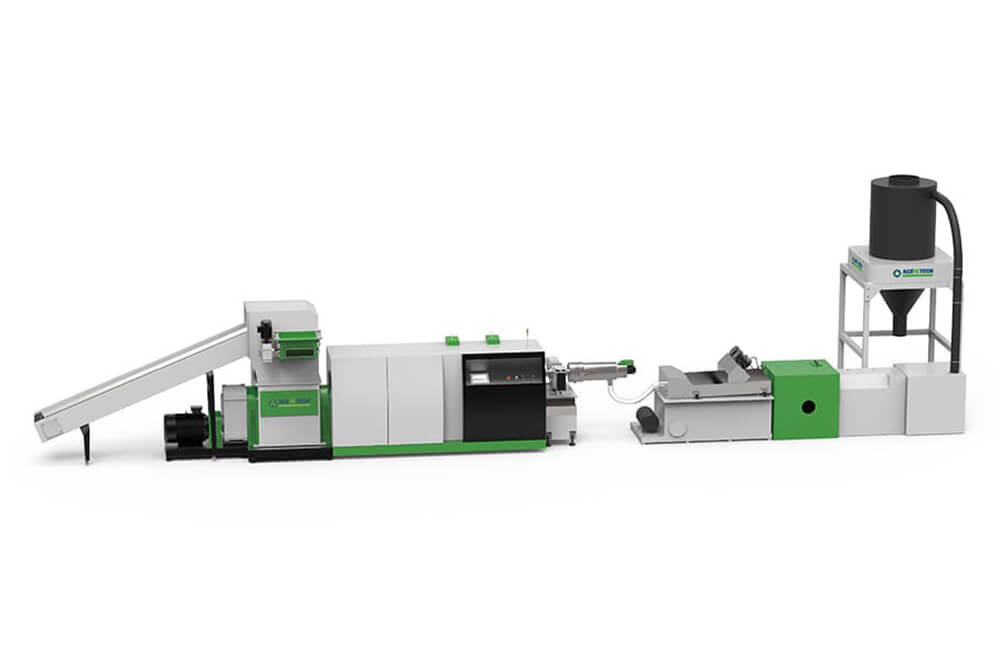

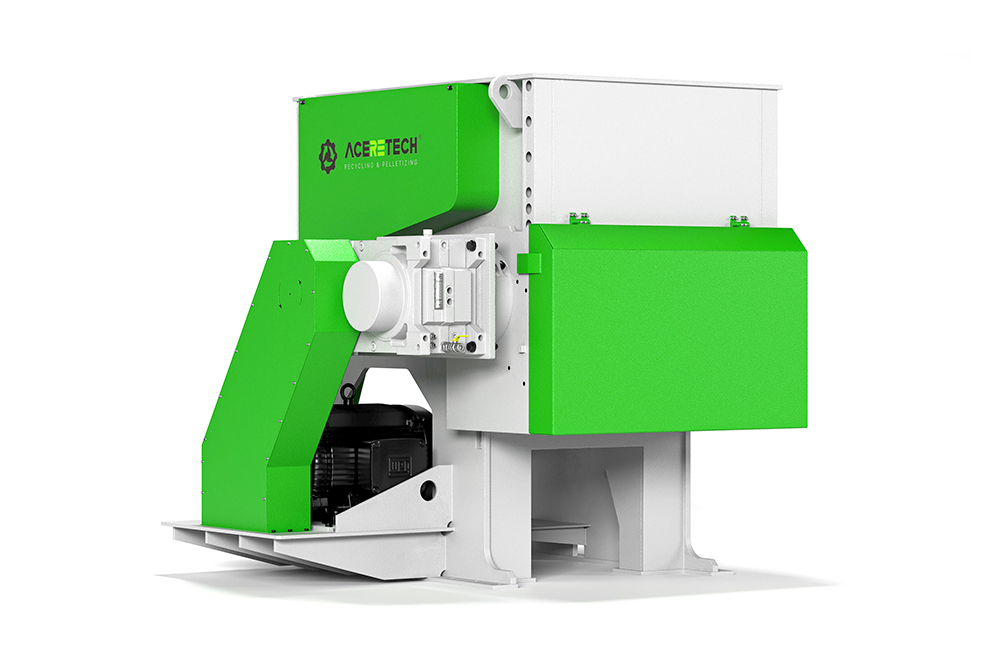

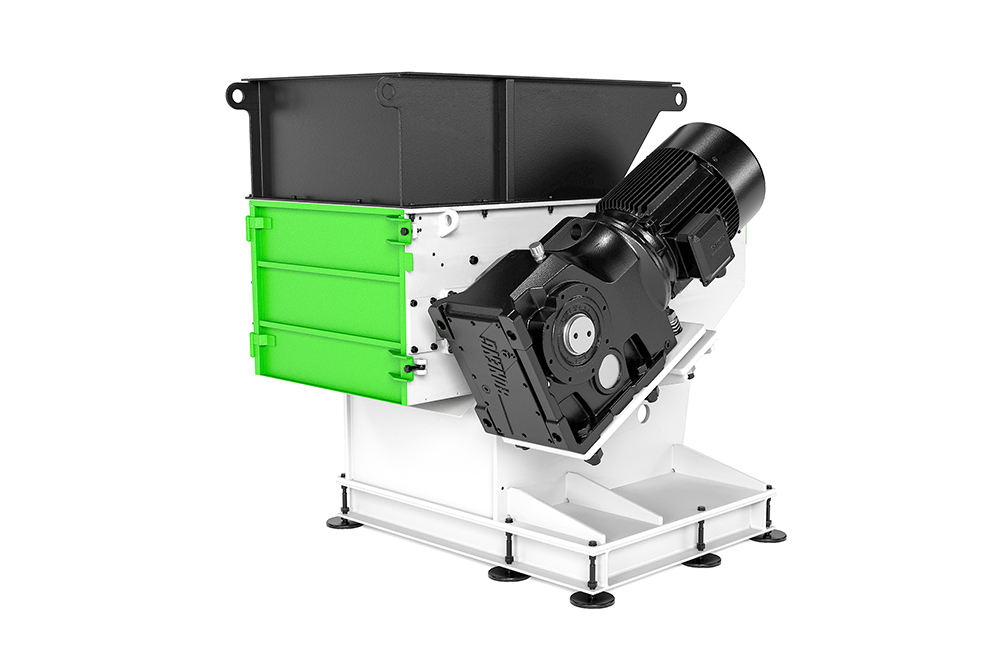

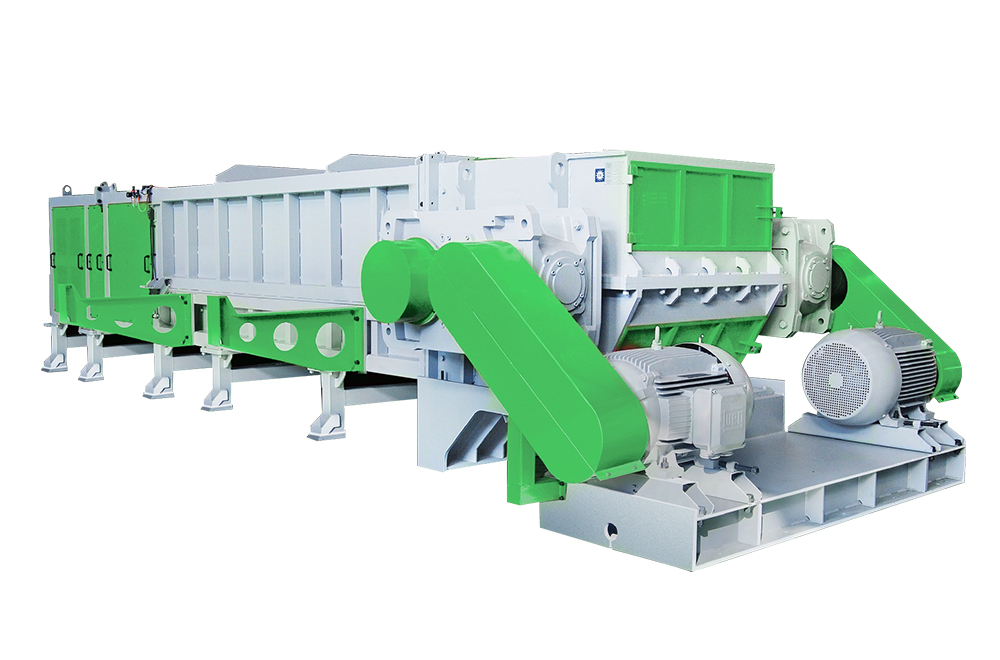

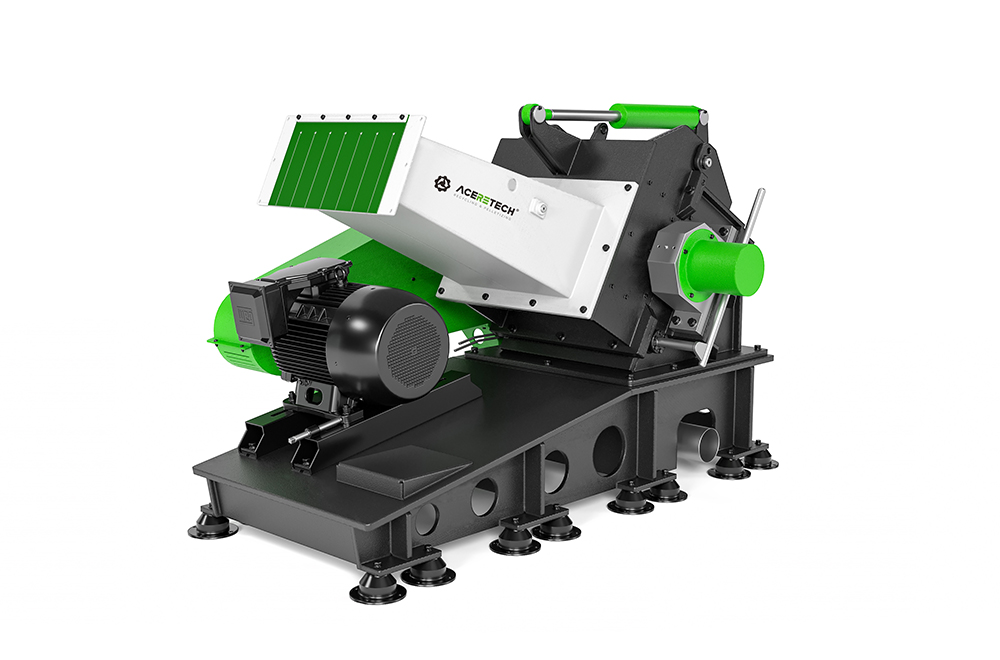

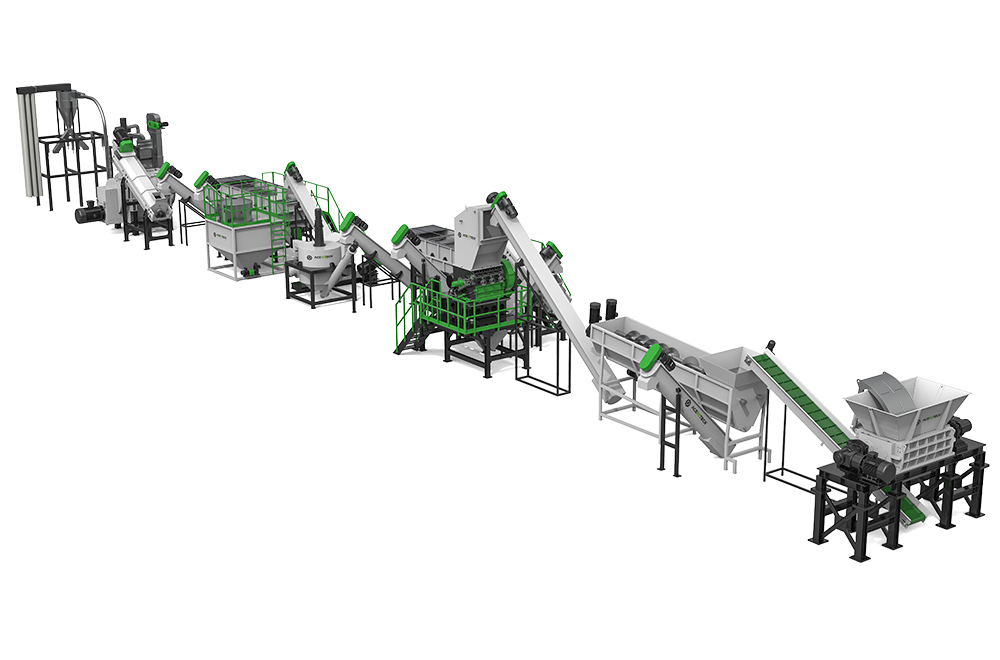

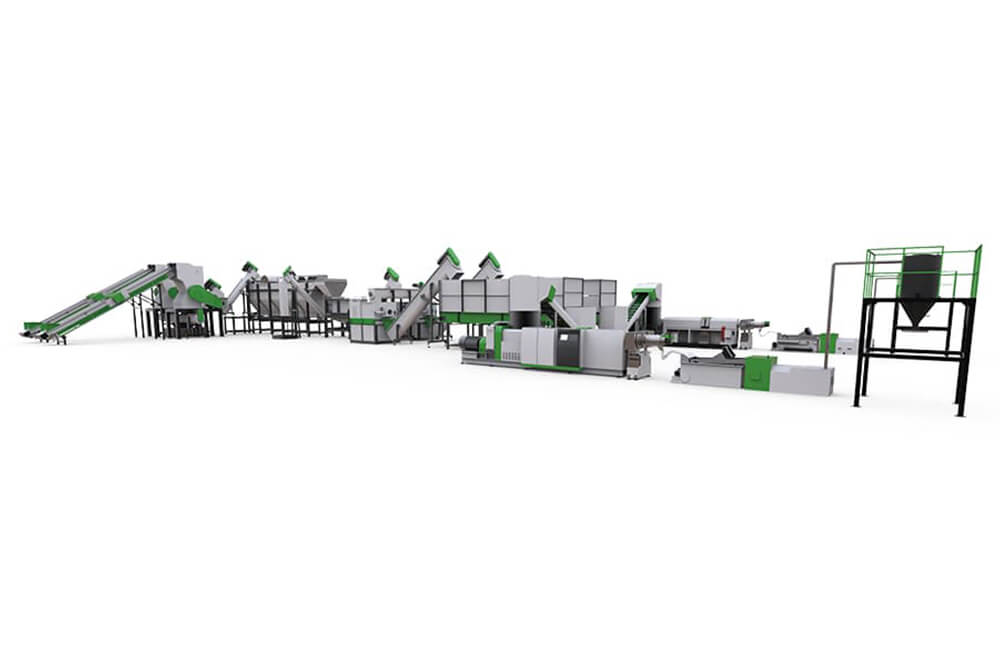

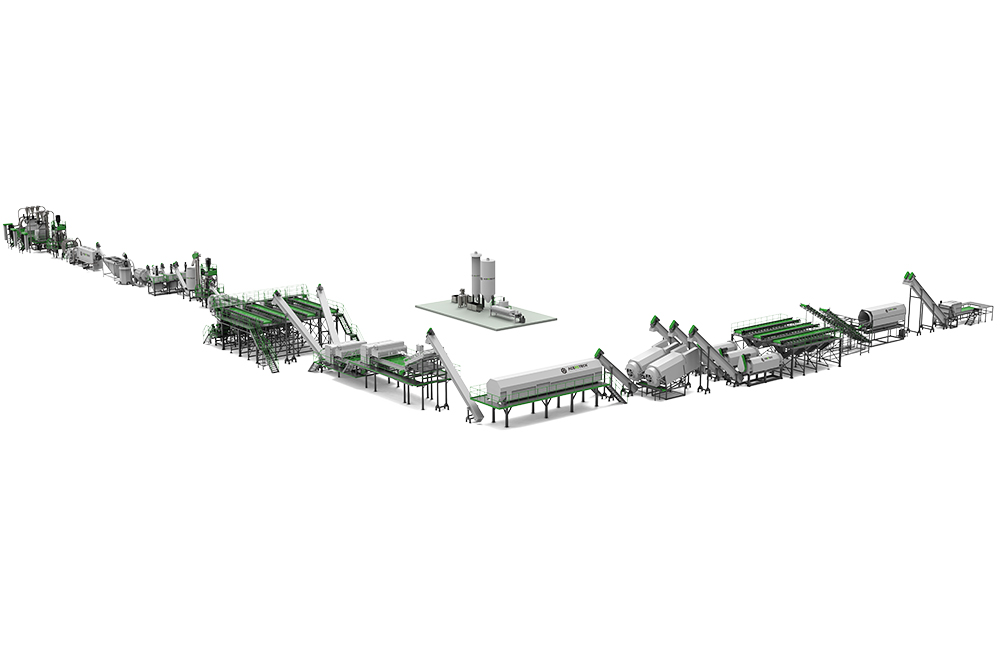

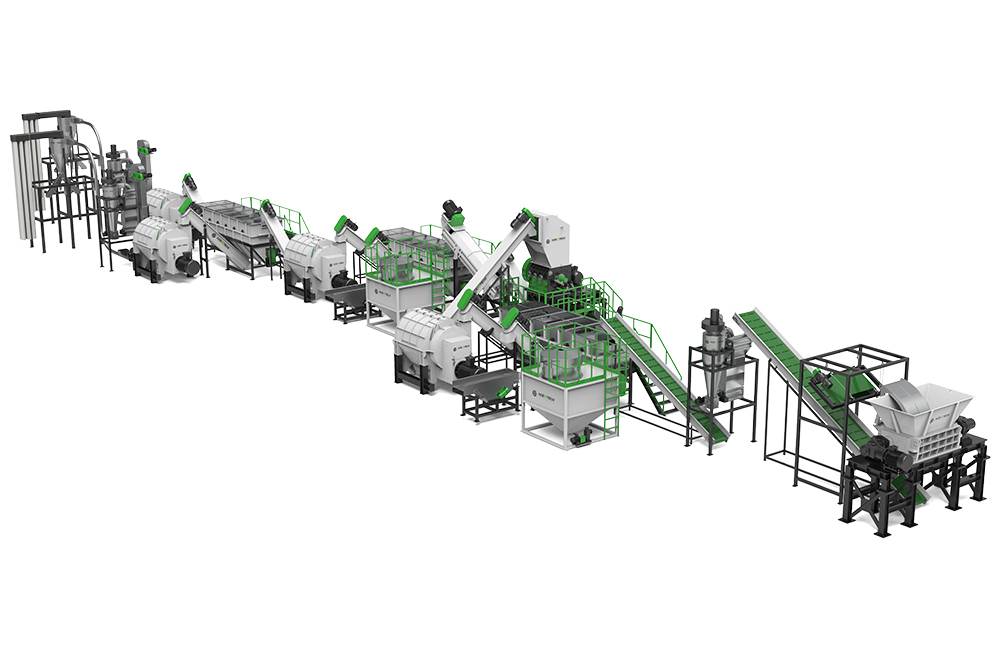

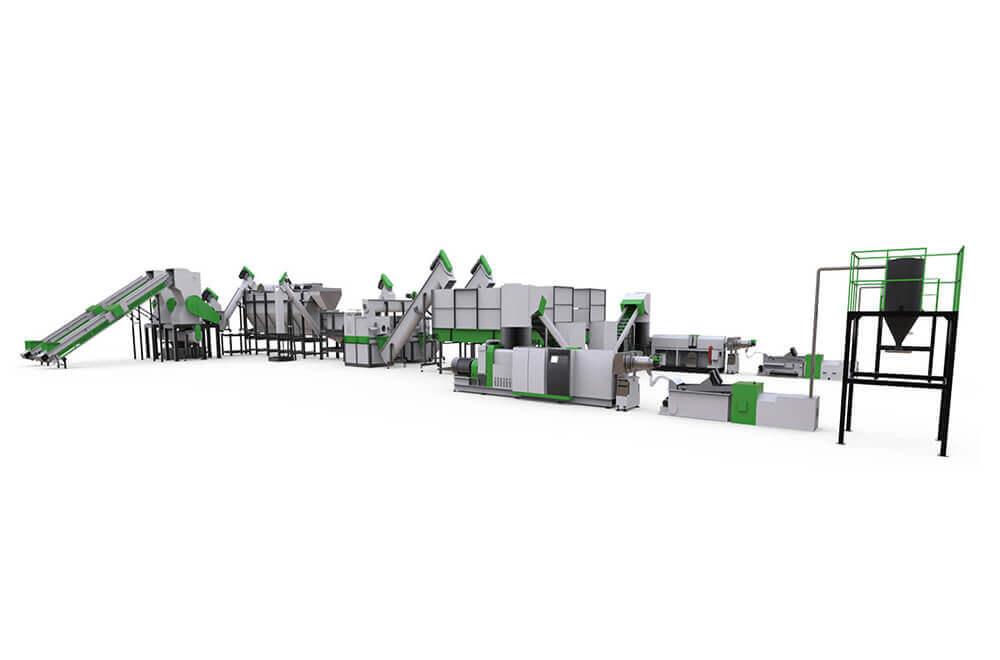

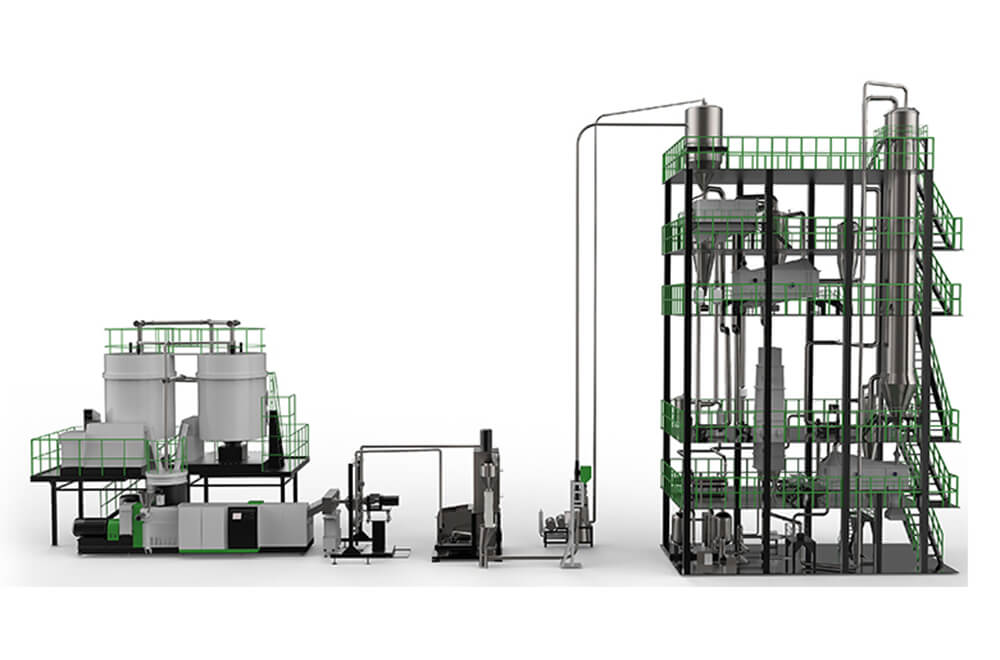

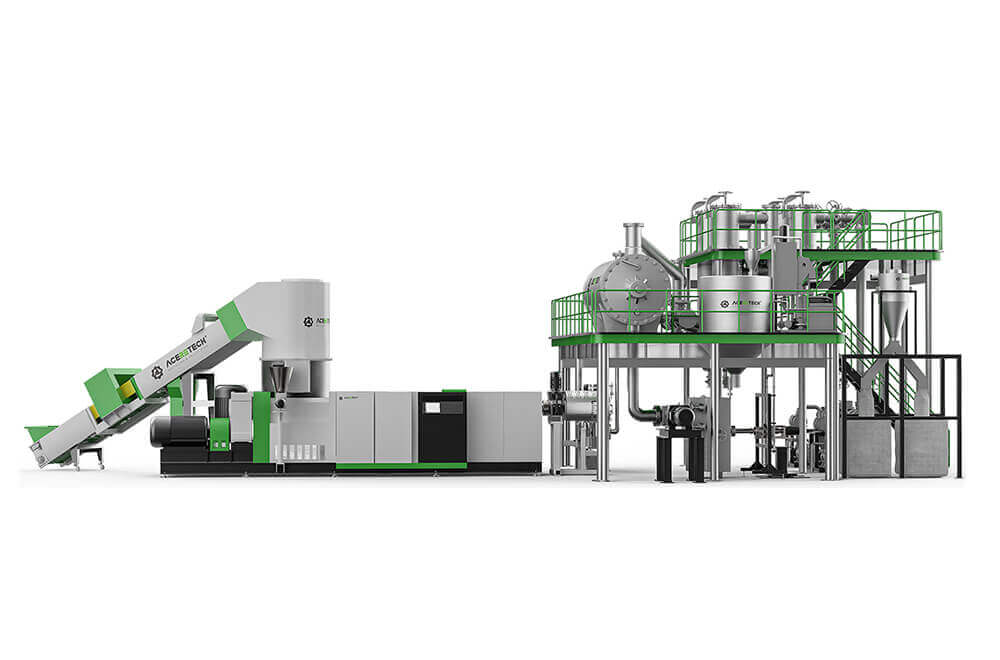

The single-shaft shredder adopts advanced heavy-duty knife roller and large-arc pusher structure, and has strong medium and fine crushing capabilities. The processing capacity of each model is between 1 and 30 tons per hour. Depending on the processing environment, an electric motor or a high-torque radial motor drive scheme can be selected. Applicable to various materials including: domestic waste, industrial waste, municipal waste, RDF derived fuel, alternative fuel, shoe factory scrap, leather scrap, chemical barrel, large blue barrel, rubber scrap, nozzle material, plastic pallet, wooden pallet, Wooden pallets, paper mill waste, industrial waste paper, etc.

Working Principle Analysis

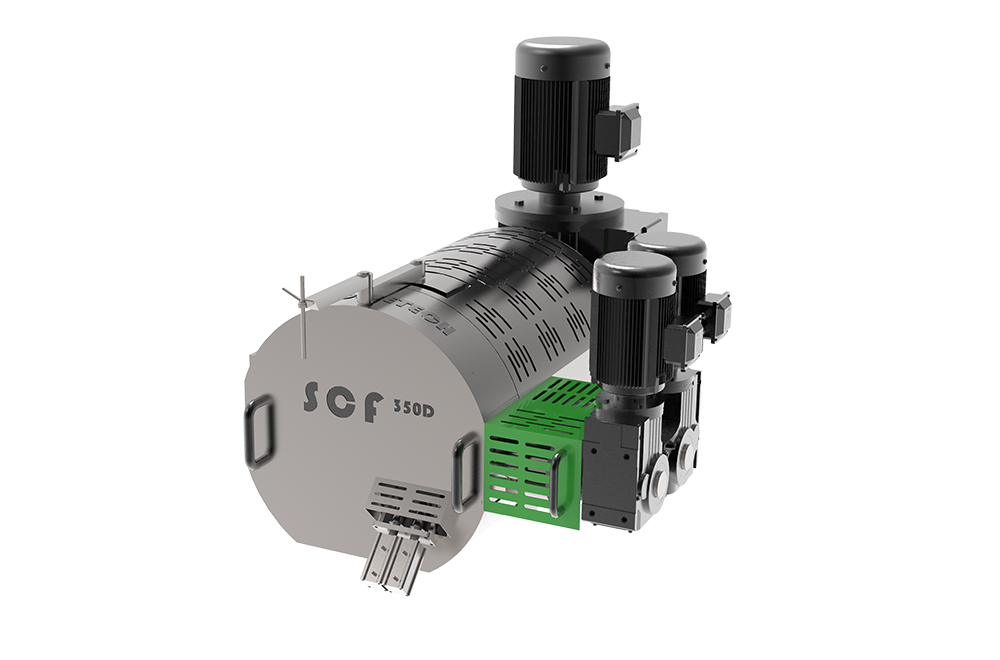

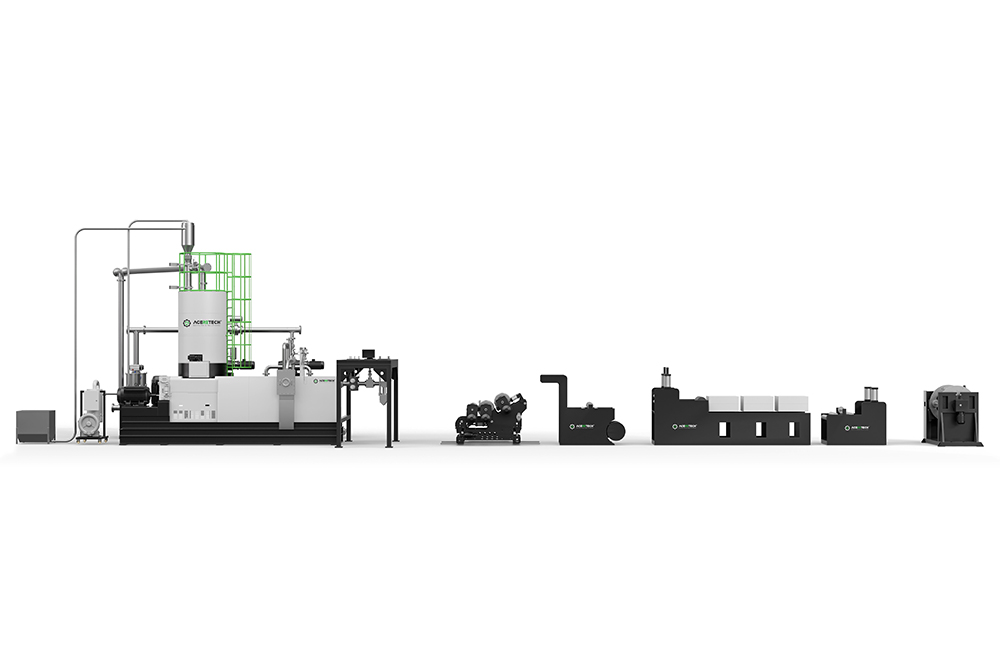

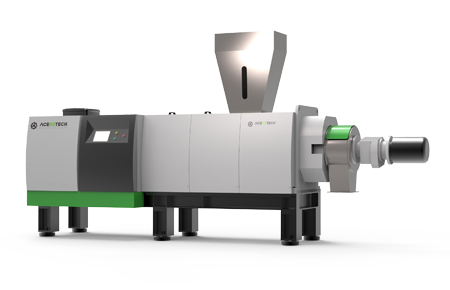

Various waste materials enter the inside of the shredding box through the feeding system, the box carries the moving knife roller and the shredding blade, and the oil cylinder pushes the push box to push the material to the vicinity of the blade. The geared motor drives the moving knife roller to rotate, and the material is torn, squeezed and sheared by the shredding blade, and the material is shredded into small pieces and discharged from the screen mesh.

.jpg)

Features

1. Multiple dustproof, bearing seat isolation structure completely eliminates material pollution to moving parts;

2. The designed triangular distribution main shaft bearing structure can also run smoothly when crushing mixed materials and hard materials.

3. The overall reducer base shock absorber improves the stability of the reducer action and avoids the casing strain caused by long-term vibration;

4. PLC controls the feeding system in real time according to the main current, which improves the effective output power;

5. The large arc cutting range and the dual-axis arrangement of the knives greatly improve the crushing efficiency;

6. The European special wear-resistant steel imported in batches, the high temperature heat treatment casting blade, the low energy consumption and the low maintenance cost.

When selecting a single-shaft shredder, it is necessary to ensure that it can reach the output, meet the requirements of crushing and discharging, easy to maintain, easy to disassemble and install the tool, wear-resistant tool material, strong shock absorption, suitable for dust, low temperature and high temperature. Environmental work.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us