What Plastics Can Be Used For Granulation?

2022-10-31

Article Paragraph

Ⅰ Plastic particles

Ⅱ Types of granulated plastics

Ⅲ Application of plastic particles

Ⅳ The classification of recycled plastic particles

Plastic particles

Plastic granules refer to granular plastics, generally divided into more than 200 kinds, with thousands of subdivisions.

Common plastic particles include general plastics, engineering plastics, and special plastics.

General purpose plastics: polypropylene, polyethylene, polyvinyl chloride, polystyrene, polyester, polyurethane, etc.

Engineering plastics: nylon, polytetrafluoroethylene, polyoxymethylene, polycarbon silicone, etc.

Special plastics: thermosetting plastics, functional polymer plastics, such as artificial kidneys.

.jpg)

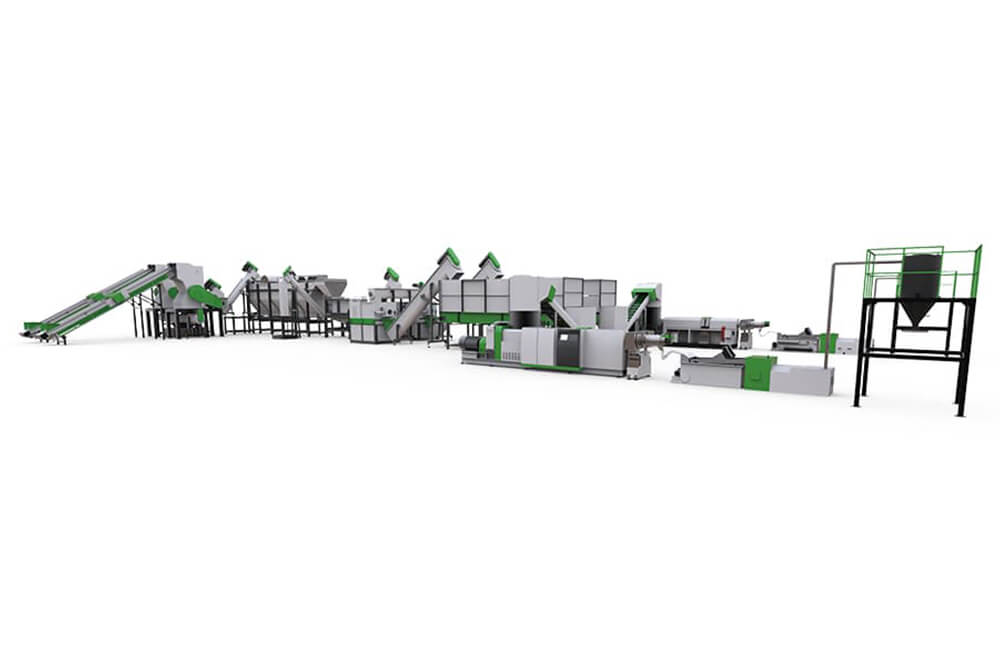

Types of Pelletizable Plastics

Everyday plastics such as PP/PE/PET/PA/PS/PC/PVC/ABS/PU/POM/PMMA can be granulated.

Introduction of PP recycled plastic: Polypropylene (PP)---translucent when unpigmented, waxy, lighter than polyethylene, better transparency than polyethylene, harder than polyethylene. Mainly used for pots, barrels, furniture, Films, woven bags, packing tapes, bottle caps, car bumpers, etc.

Introduction of PE recycled plastics: Polyethylene (PE)--- milky white translucent and waxy when uncolored; it feels slippery when touched by hand, flexible and flexible, slightly stretchable, generally low-density polyethylene is softer and more transparent Better, HDPE is harder, mainly used for mulch, tote bags, water pipes, oil drums.

PS is polystyrene plastic, which is easy to color and has good transparency. It is mostly used to make lampshades, toothbrush handles, toys, and electrical parts. It is resistant to acid and alkali corrosion, but is easily soluble in organic solvents such as chloroform, dichloroethylene and banana water.

PVC is a polyvinyl chloride plastic with bright color, corrosion resistance, firmness and durability. Due to the addition of some toxic auxiliary materials such as plasticizers and anti-aging agents in the manufacturing process, its products generally do not store food and medicine.

ABS is a plastic polymerized by acrylonitrile, butadiene, and styrene. It is eye-catching in color, heat-resistant and strong. The outer surface can be plated with metal films such as chrome and nickel. It can be used to make keys, buttons, knife holders, TV casings, umbrella handles Wait.

PA is nylon plastic, which is tough, firm and wear-resistant. It is often used to make combs, toothbrushes, clothes hooks, fan bones, mesh bag ropes, fruit packaging bags, etc. It is non-toxic, but cannot be in contact with acid and alkali for a long time. Features: wear-resistant, pressure-resistant, high-strength indoor and long service life, individual models such as PA66 high temperature resistance up to 2200, the disadvantage is that it is easy to change performance under the sun, easy to break, and poor weather resistance.

PU: Common name polyurethane. Mainly used for handrail (foam) accessories.

POM: Common name Saigang. Mainly used for wear-resistant parts such as foot pads, casters, door hinges, hinges, etc. The performance is wear-resistant and pressure-resistant, but the dimensional stability is poor.

PMMA: plexiglass (commonly known as acrylic). There are five kinds of transparent materials in plastic, and PMMA is one of the most transparent materials. The workpiece has an acetic acid smell when it is cut, and it is easy to deform and deform. It can be shaped and bent by soaking in boiling water. Disadvantages: The surface is easily scratched, the hardness is low, and it is easy to crack when bent, and the price is more than 20% higher than that of ABS.

PC: commonly known as polycarbonate. This variety is also a transparent material, with high surface hardness, scratch resistance, strong impact resistance, high strength, and good weather resistance (that is, not afraid of sunlight). The sun panel of the screen clapboard in the furniture is hollow extruded from this material. Features: High price and cost, about 40% higher than PMMA.

.jpg)

.jpg)

.jpg)

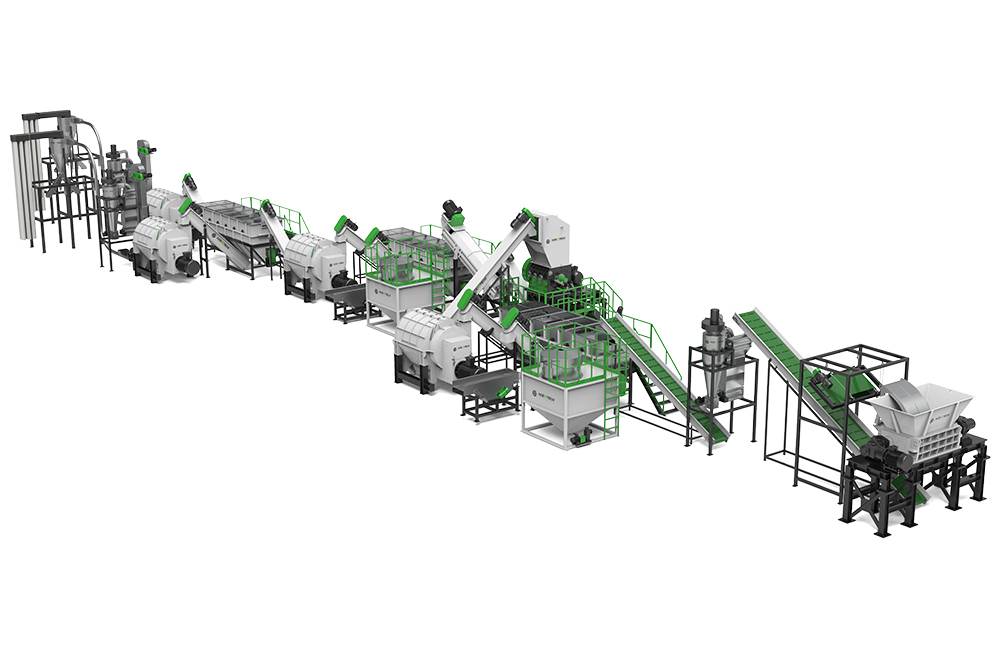

Plastic particle application

In daily life, recycled particles can be used to manufacture various plastic bags, barrels, basins, toys, furniture, stationery and other household utensils and various plastic products.

Apparel industry: recycled particles can be used to make clothing, ties, buttons, zippers.

In terms of building materials: recycled particles can be used to manufacture various building components, construction tools, plastic doors and windows, and mortar buckets.

Agriculture: Regenerated granules can be used to make agricultural film, water pipes, agricultural machinery, fertilizer packaging bags, and cement packaging bags.

In terms of machinery industry: the regenerated particles can be used to manufacture machine parts after special formulation: various forms of bearings, gears, cams, different gears, sealing rings, various blades, and various water pump impellers.

Chemical industry: Regenerated particles can be used as reactors, pipes, containers, pumps, valves, etc., and are used in chemical production sites to solve corrosion and wear.

Recycled particles are also widely used in electrical industry and telecommunication industry.

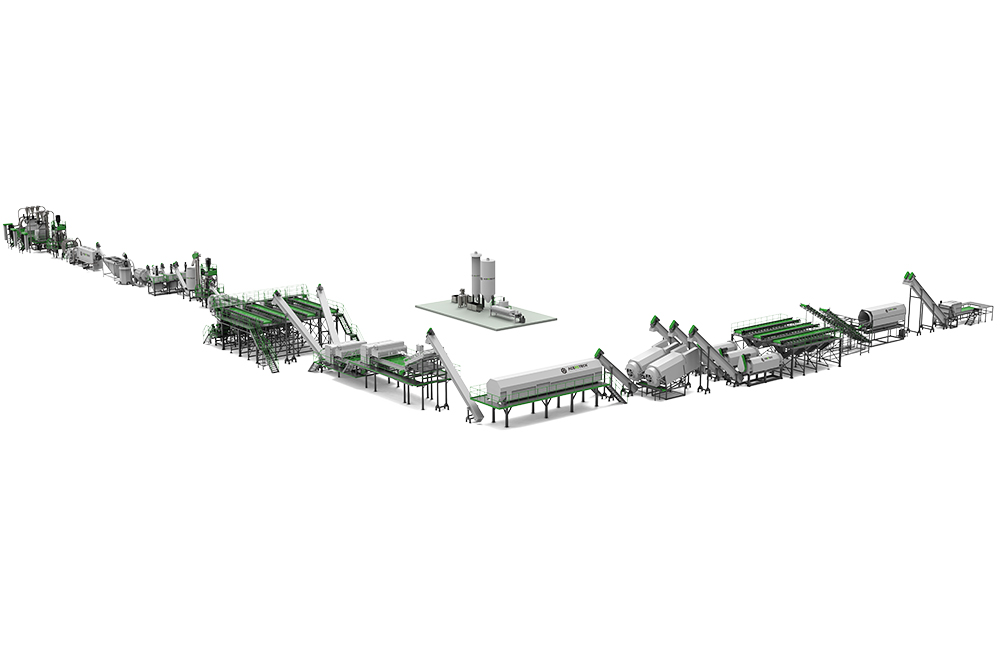

Classification of recycled plastic pellets

Recycled plastic granules are mainly classified into grades according to the different raw materials used and the characteristics of the processed plastic granules, and are generally divided into grades one, two, and three.

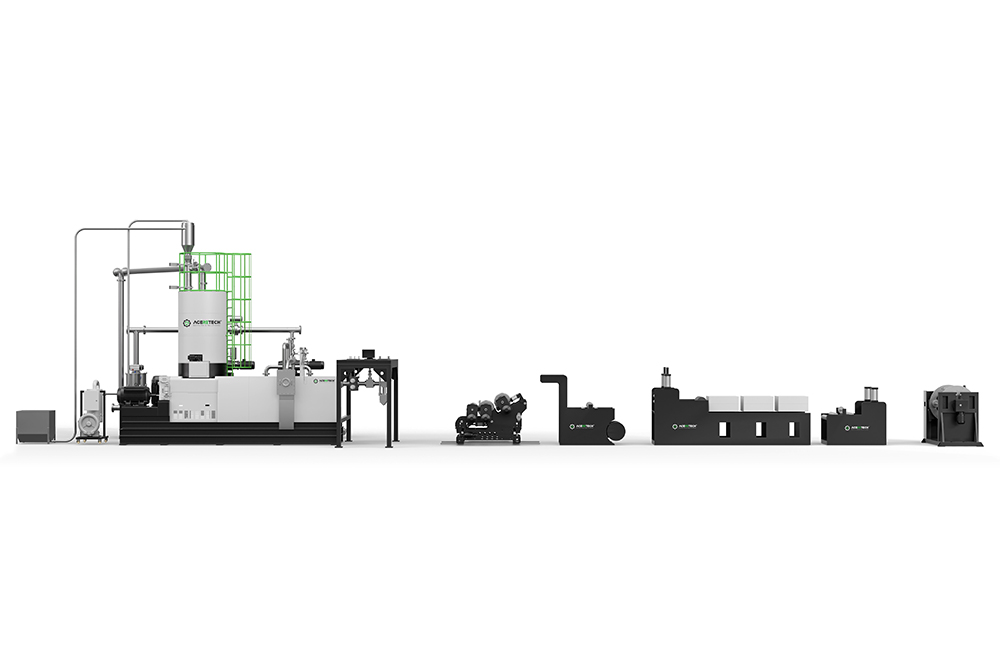

primary material

It means that the raw materials used are leftovers that have not fallen on the ground, or are called lower scraps, some are nozzle materials, rubber head materials, etc., and the quality is relatively good, that is, they have not been used. In the process of processing new materials, the remaining small corners, or raw materials of poor quality. The granules processed from these wool materials have better transparency, and their quality can be compared with that of new materials, so they are first-grade or super-grade materials.

Secondary material

It means that the raw materials have been used once, except for high-pressure granulation. Most of the imported large-sized pieces are used in high-pressure granulation. If the imported large-sized pieces are industrial films, they have not been exposed to wind and sun, so their quality is also very good. The transparency of the resulting particles is good, and it should also be judged according to the brightness of the particles and whether the surface is rough.

tertiary material

Refers to the raw material has been used twice or more times, the processed particles, its elasticity, toughness and other aspects are not very good.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us