How To Use Waste Plastic ?

2022-10-31

Manufacturers who have been engaged in the plastics industry for many years will answer your questions. There are three ways to recycle:

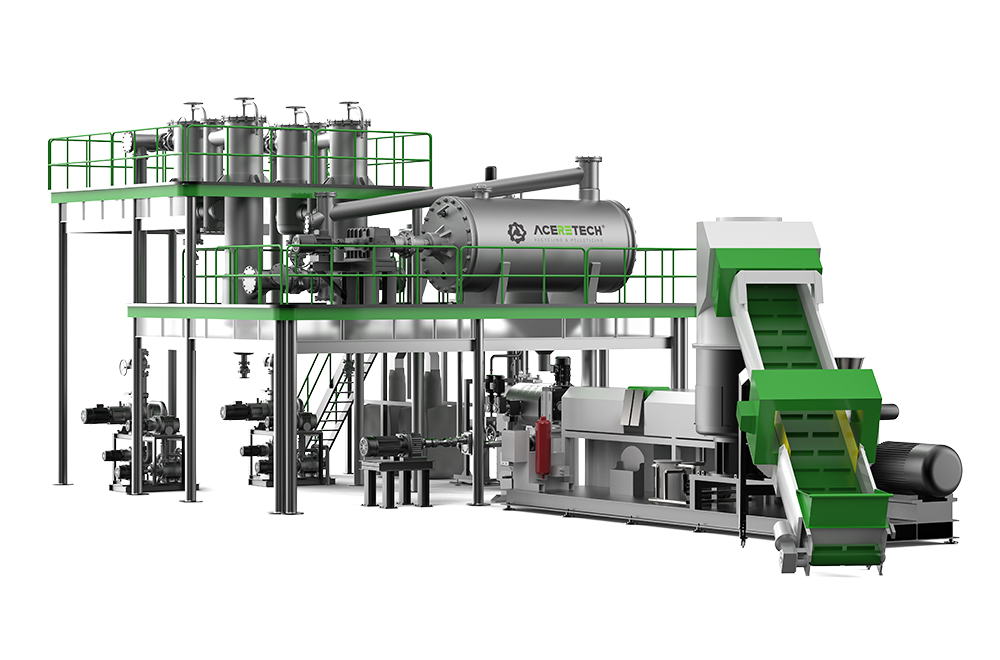

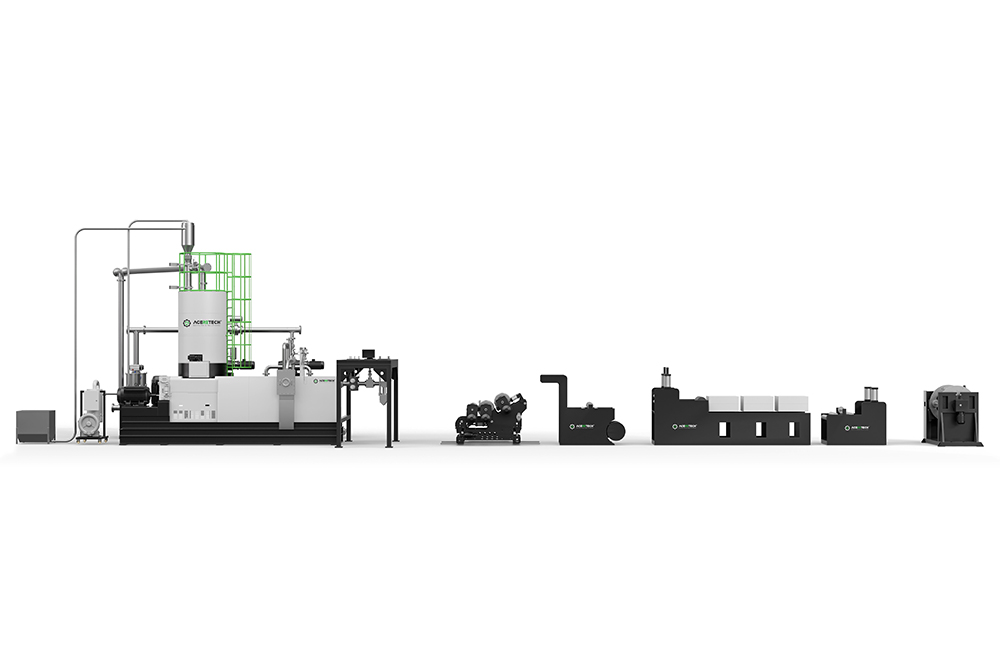

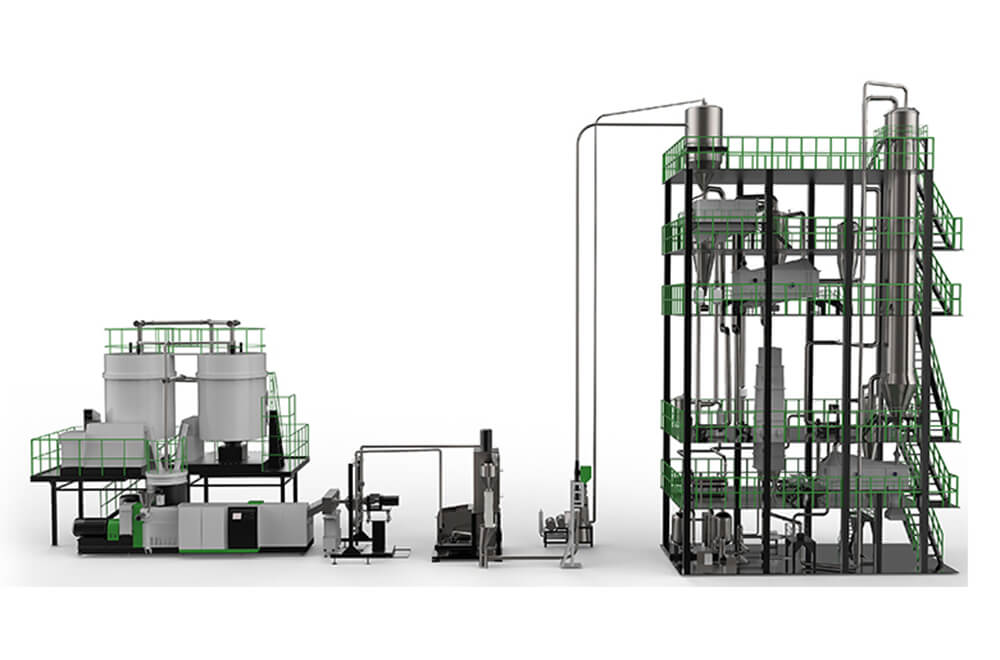

1. Thermal decomposition treatment This method is to heat and decompose waste plastics into oil or gas, or use them as energy or reuse chemical methods to separate them into petrochemical products for utilization. The process of thermal decomposition is: the polymer is depolymerized at high temperature, and the molecular chain is broken and decomposed into smaller molecules and monomers. The thermal decomposition process is different, and the final product is different, which may be in the form of a monomer, a low molecular weight polymer or a mixture of various hydrocarbons. Which process to choose oilification and gasification should be determined according to the actual demand. The methods used are: melting tank type (for PE, PP, random PP, PS, PVC, etc.), microwave type (PE, PP, random PP, PS, PVC, etc.), screw type (for PE, PP, etc.) , PS, PMMA). Tube evaporator type (for PS, PMMA), fluidized bed type (for PP, random PP, cross-linked PE, PMMA, PS, PVC, etc.), catalytic decomposition type (for PE, PP, PS, PVC, etc.). The main difficulty in thermally decomposing plastics is that the thermal conductivity of plastics is poor, which makes industrial large-scale thermal decomposition and thermal cracking difficult to carry out. In addition to thermal decomposition, there are other chemical treatment methods, such as thermal cracking, hydrolysis, alcoholysis, alkali hydrolysis, etc., which can recover various chemical raw materials.

.jpg)

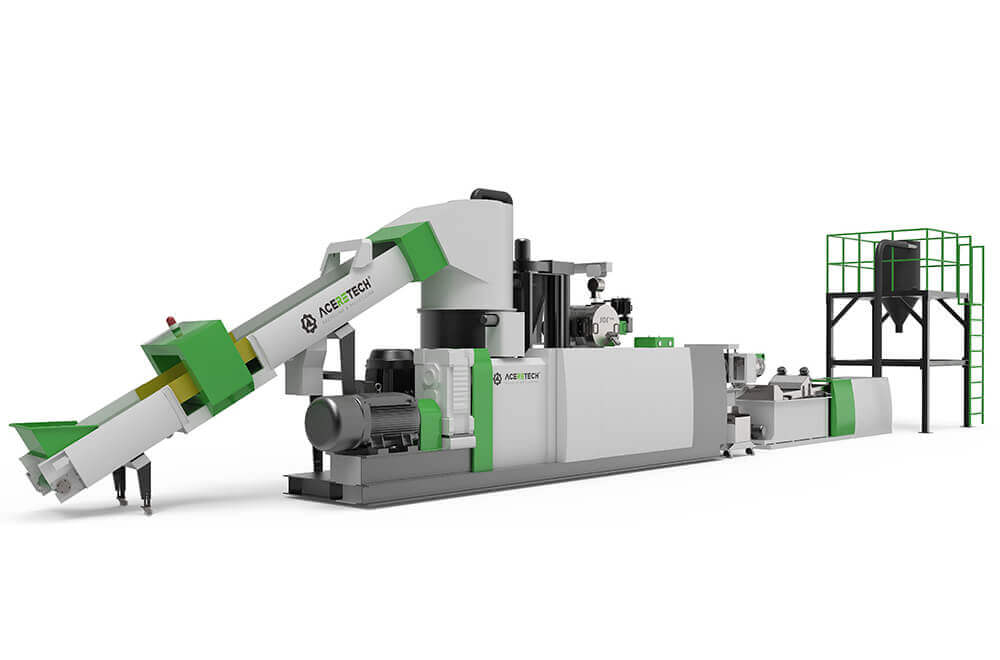

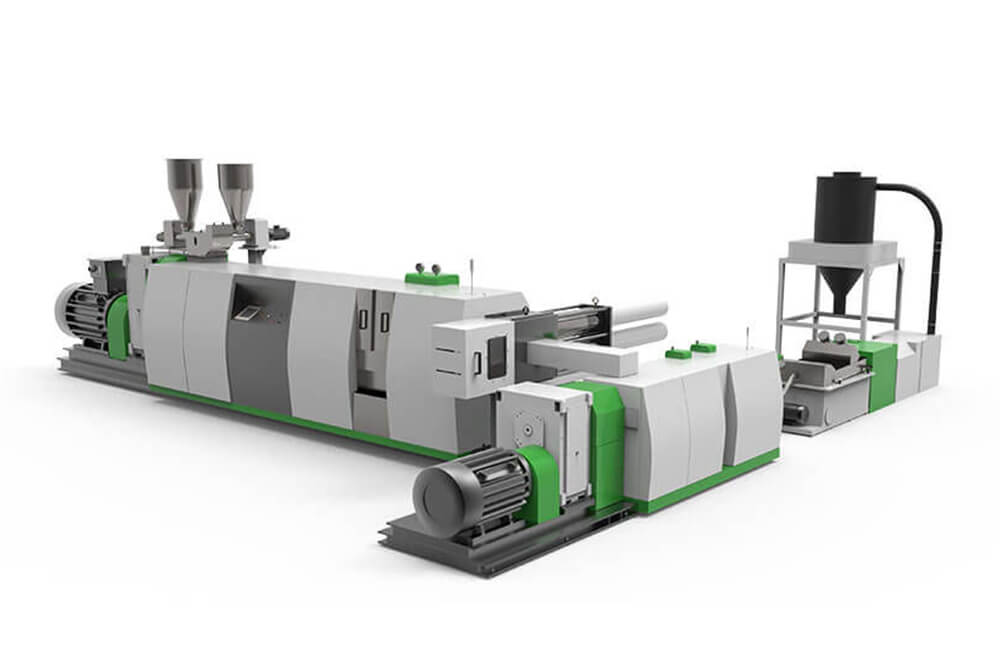

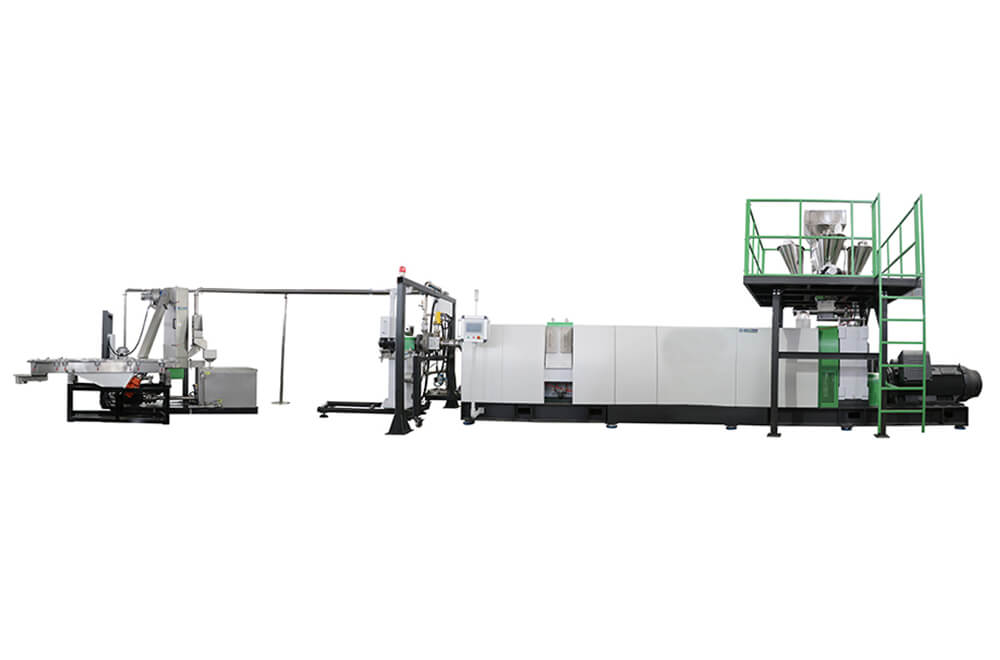

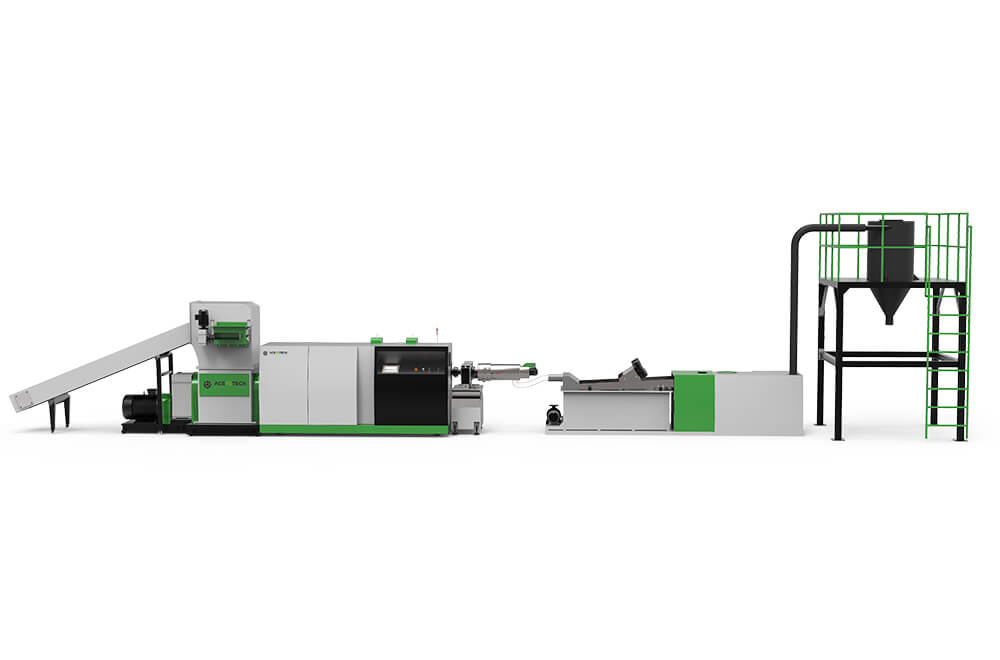

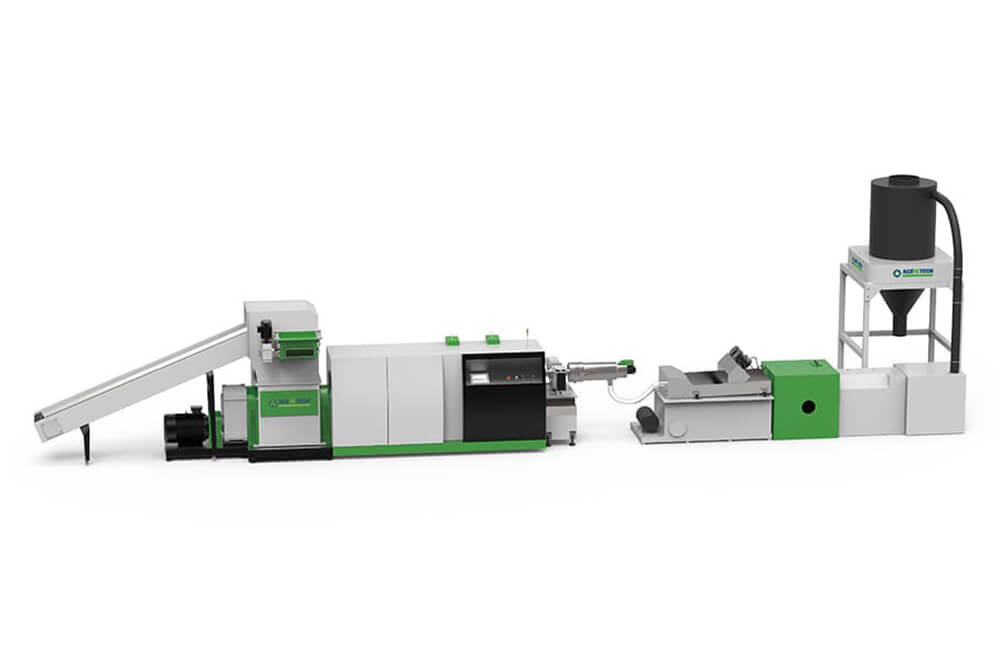

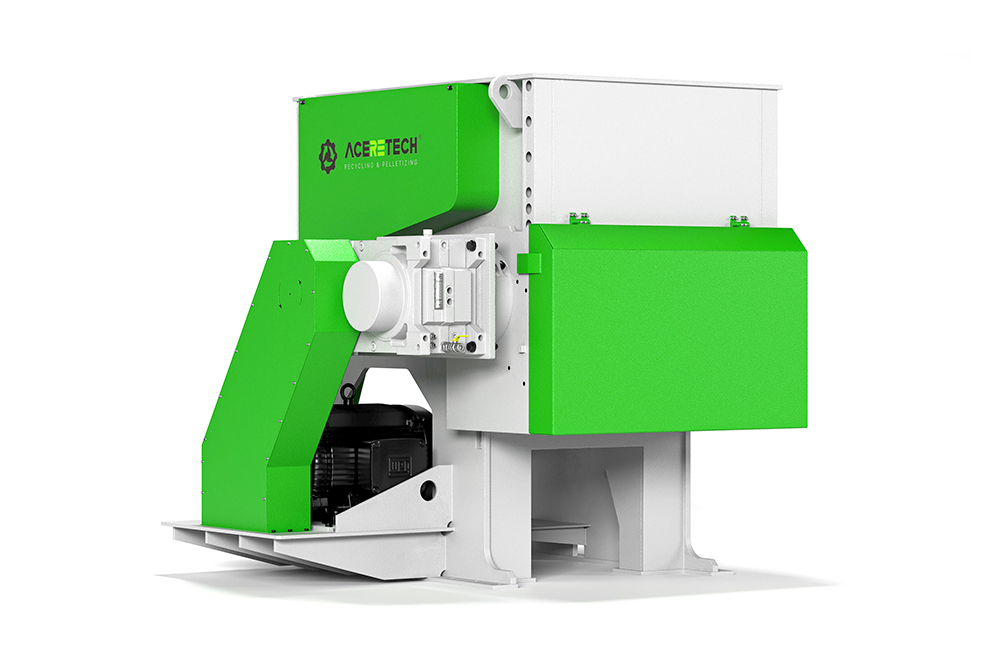

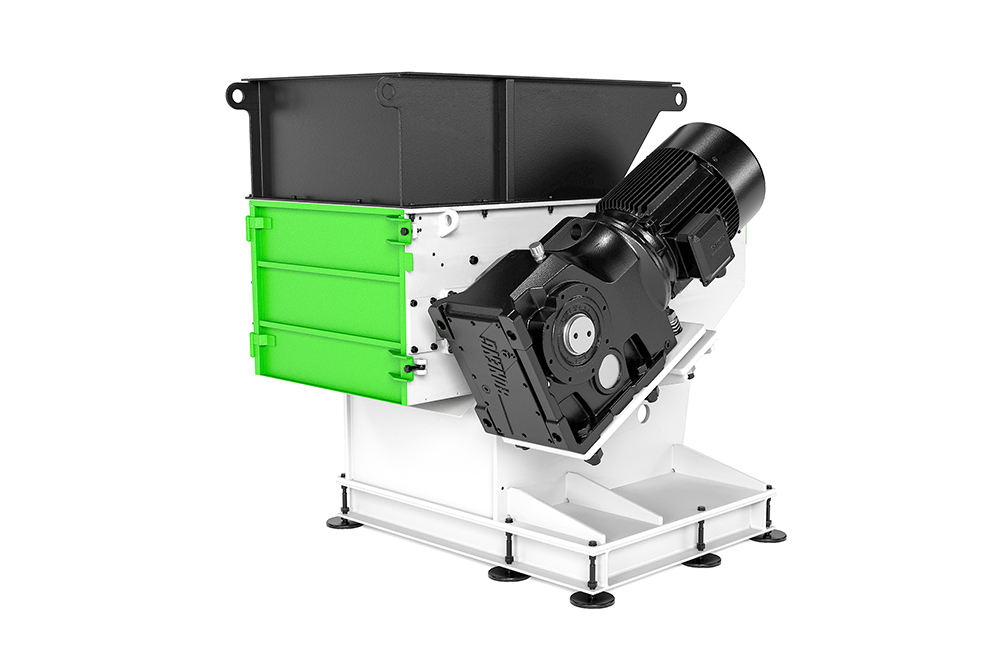

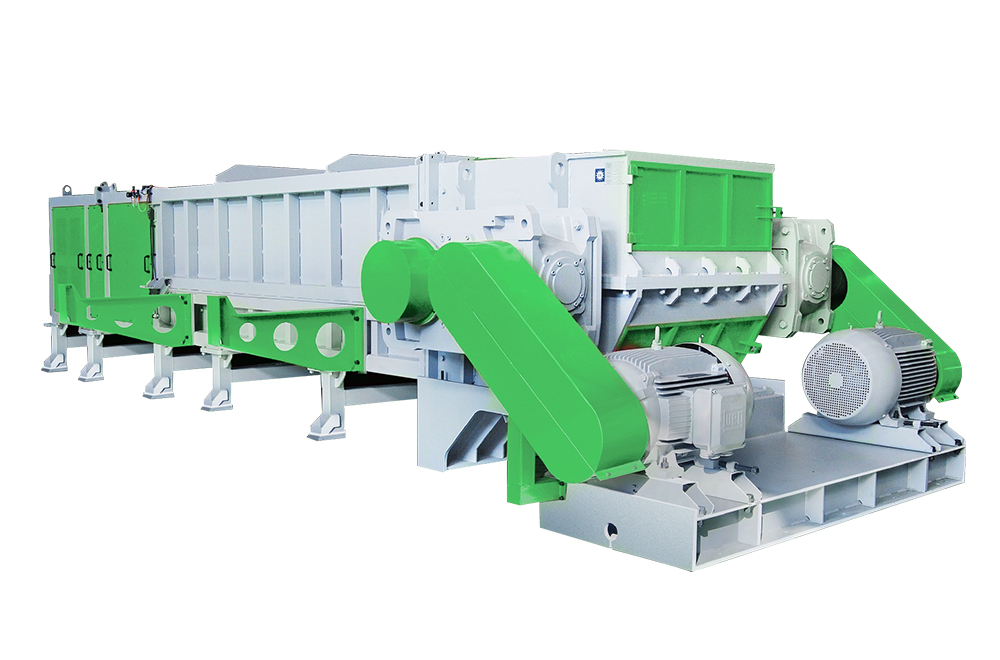

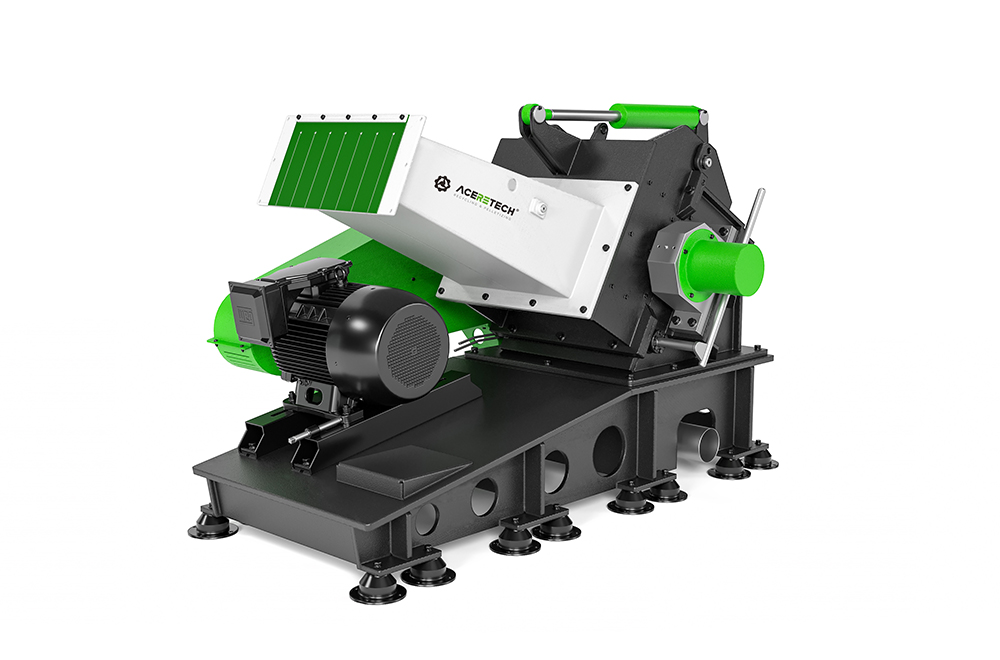

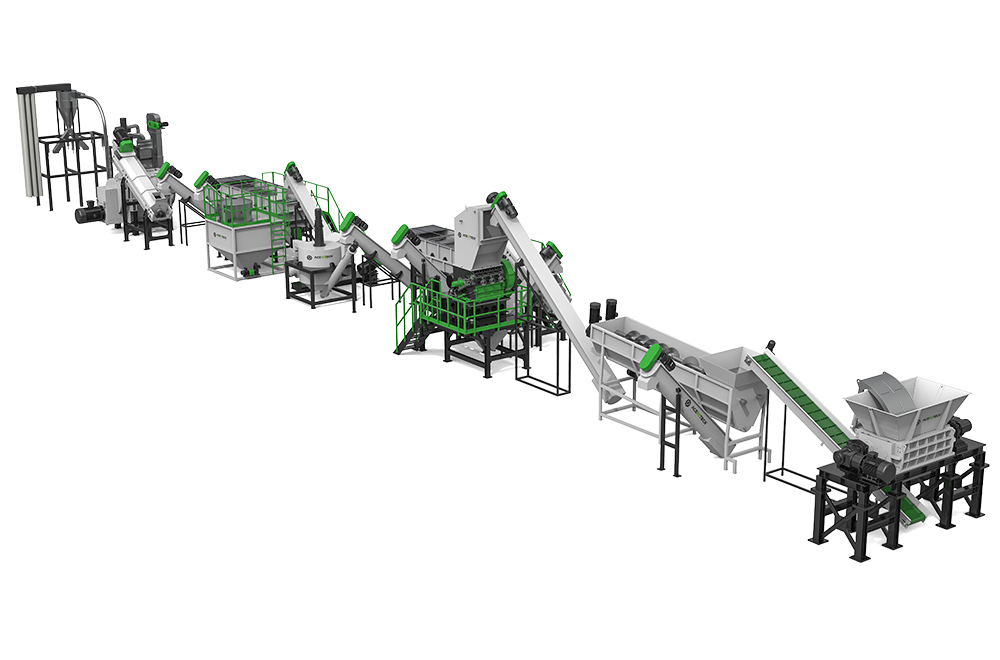

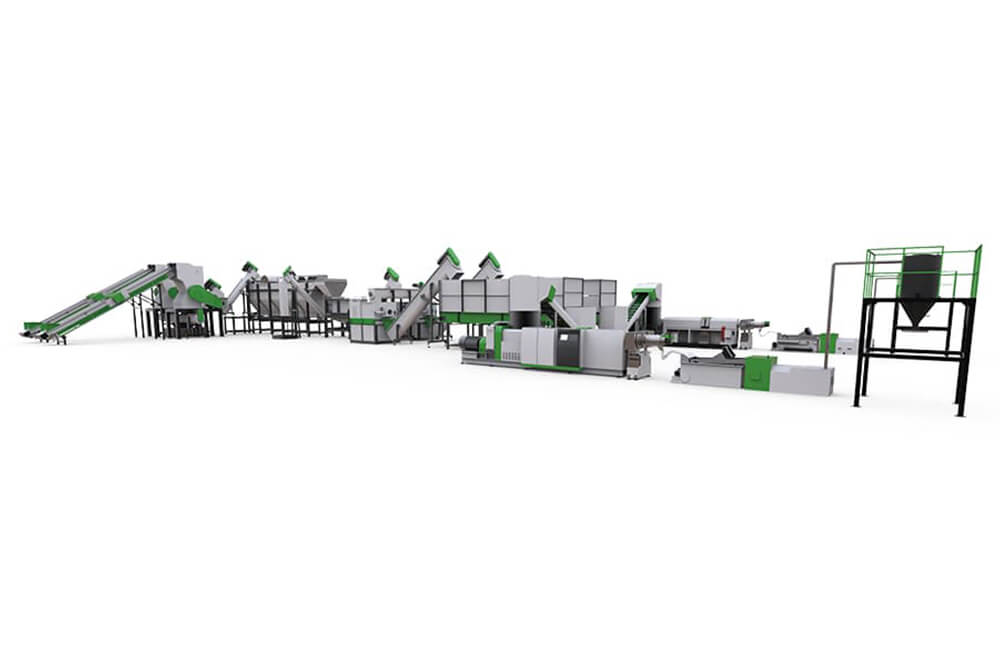

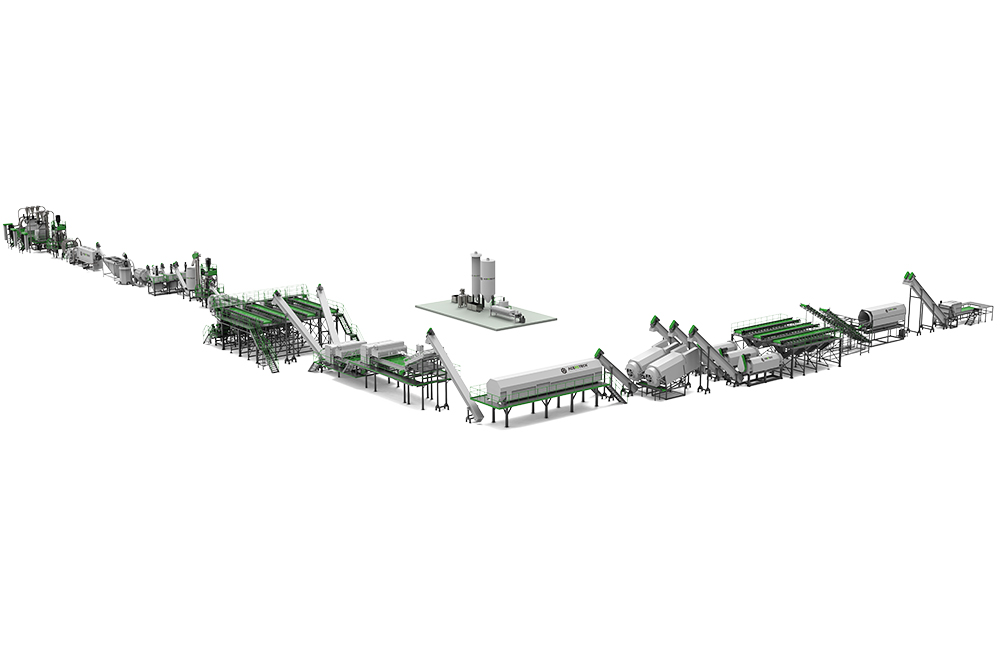

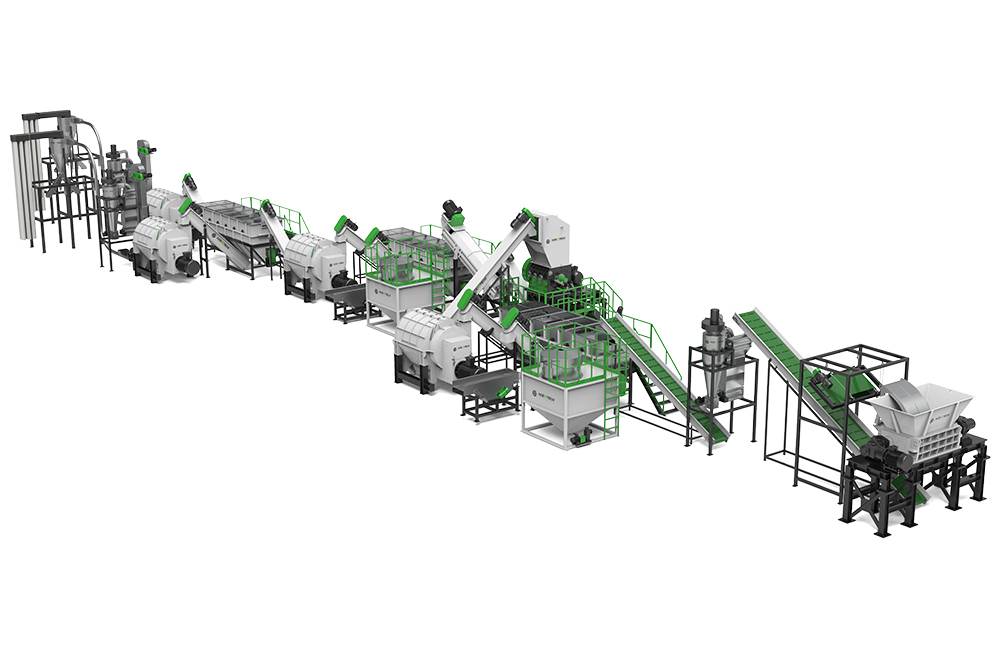

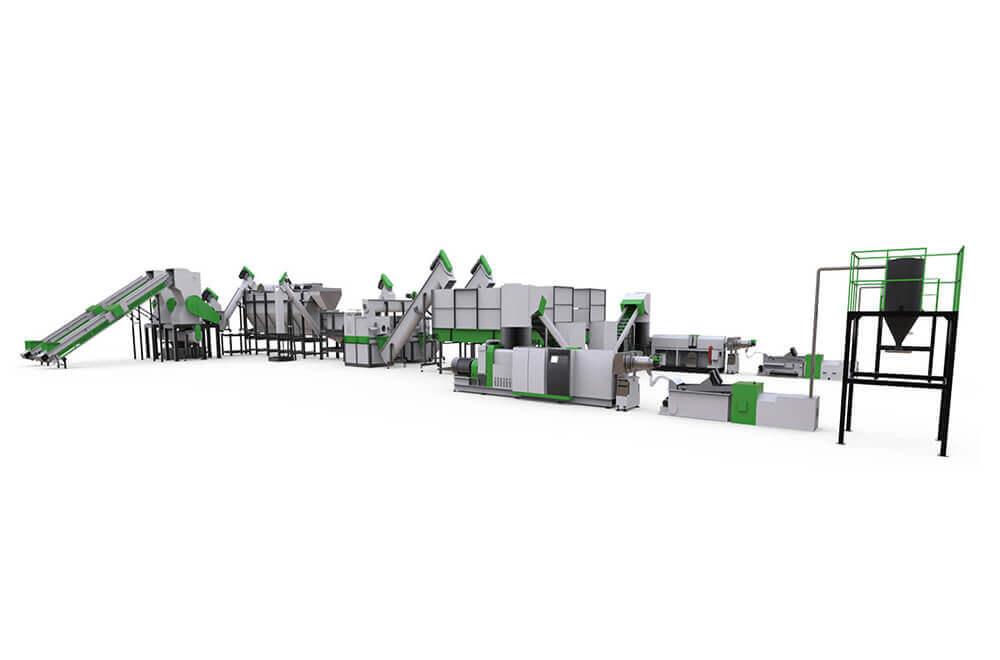

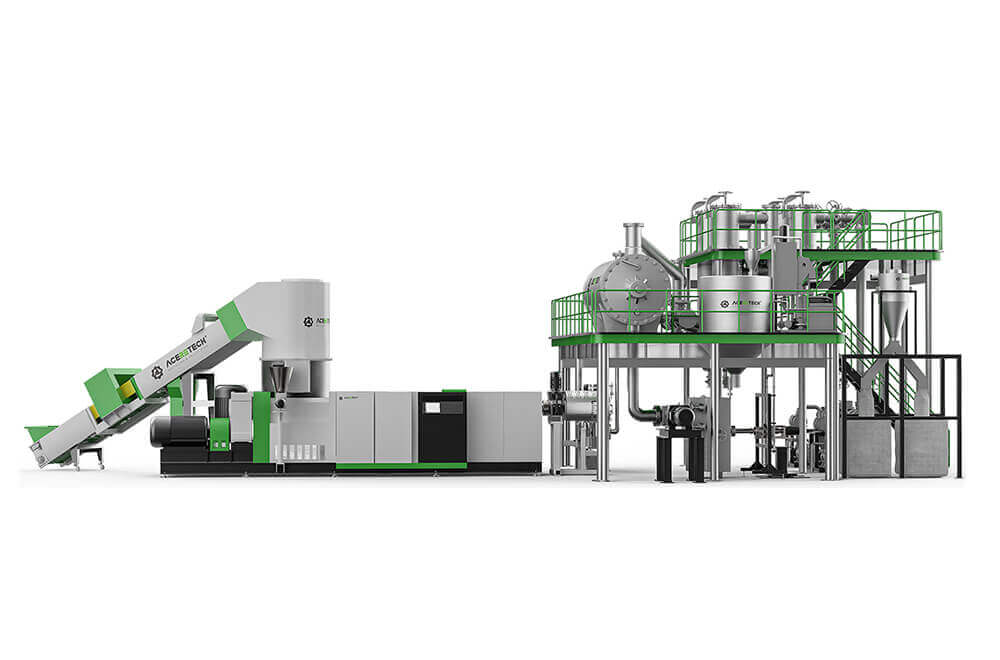

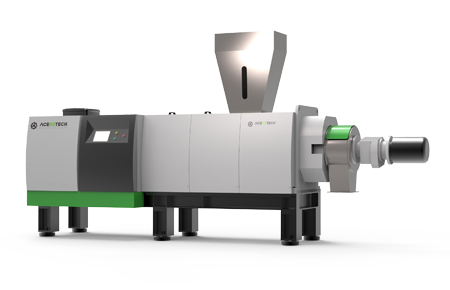

2. Melt recycling and utilization This method is to sort, shred, crush, clean, melt granulate, plasticize and extrude waste plastics into plastic products. For the waste products and scraps from resin production plants and plastic processing plants, various products with better quality can be produced by this method. The sorting and cleaning of waste plastics used in the society is more troublesome and the cost is higher. It is generally used to make coarse and low-grade products.

.jpg)

3. Composite reuse This method is to crush waste plastics, such as PS foam products, PU foam, etc. into pieces of a certain size, and then mix them with solvents, adhesives, etc. to make lightweight boards and pads.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us