ASP Shredding and Pelletizing System for Recycling PVDF Film/Lumps

PVDF film is an electrical film made of Polyvinylidene Fluoride. Because of its weather resistance and insulation properties, it is now one of the key raw materials for the insulating backplate of solar cell power generation modules.

Main PVDF film manufacturers for solar power generation are foreign manufacturers such as Akma, Japan Denka, and South Korea's SKC. Most domestic solar cell power module manufacturers can only import-related materials from abroad. However, after nearly 3 years of research and development, ACERETECH's customers have successfully mastered several core technologies and production processes for the large-scale production of PVDF films, and have become one of the few domestic companies with relatively mature technologies that can independently produce films.

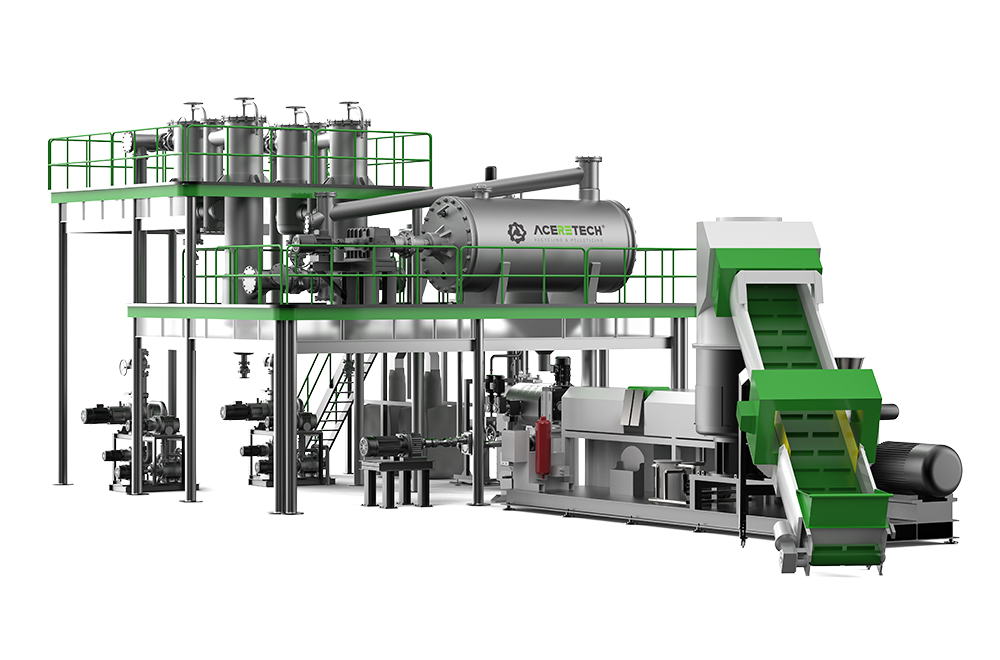

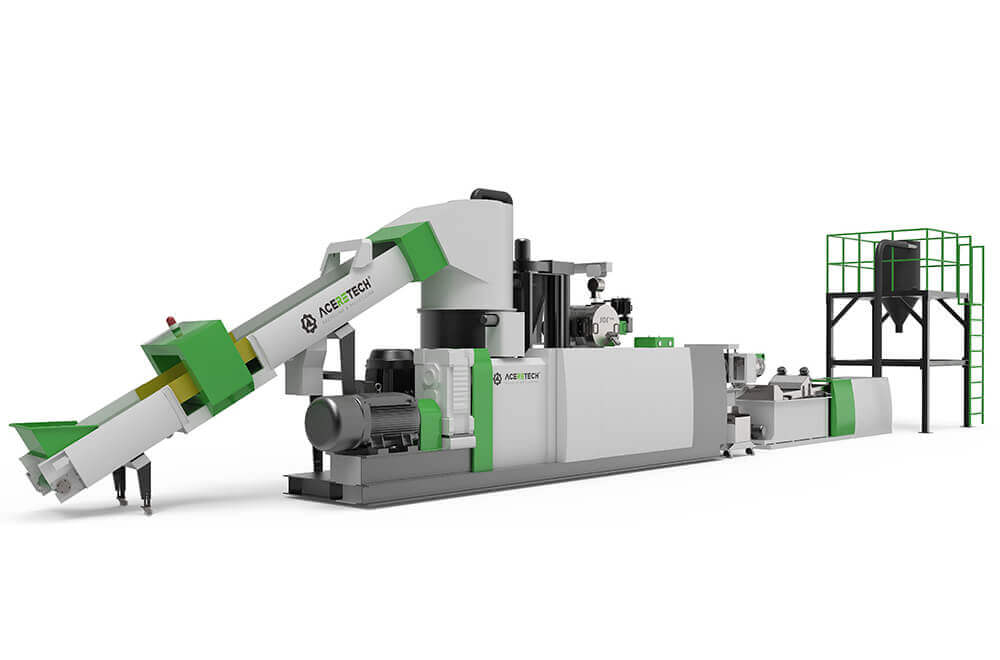

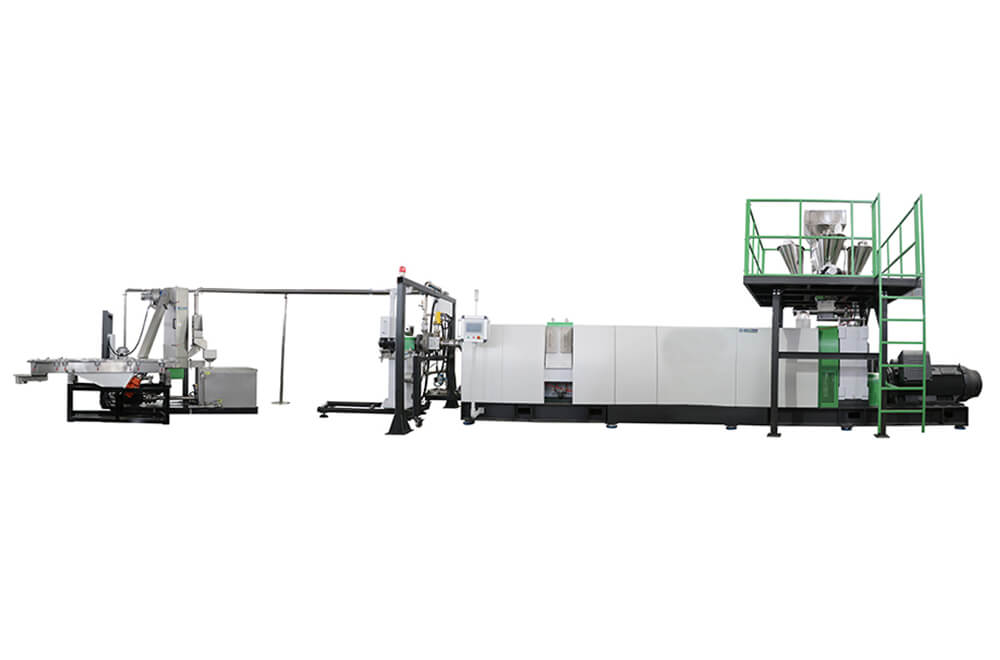

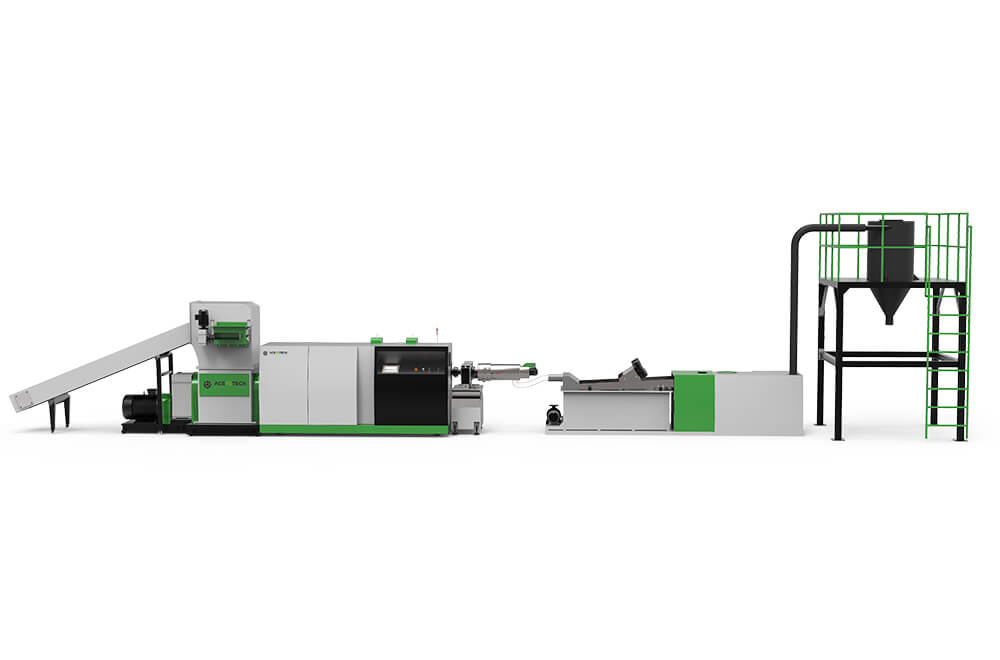

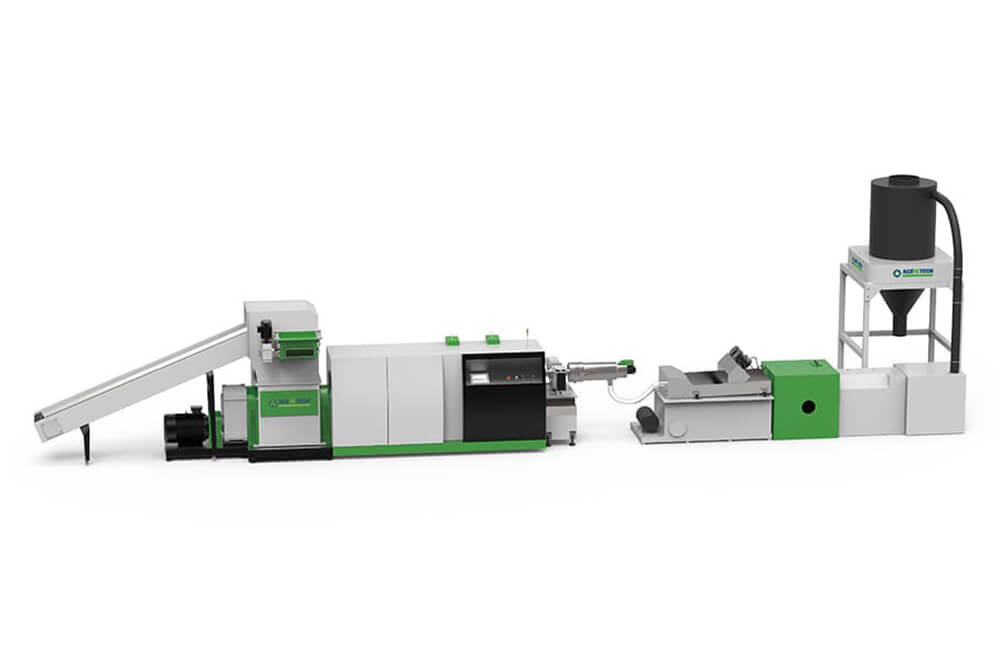

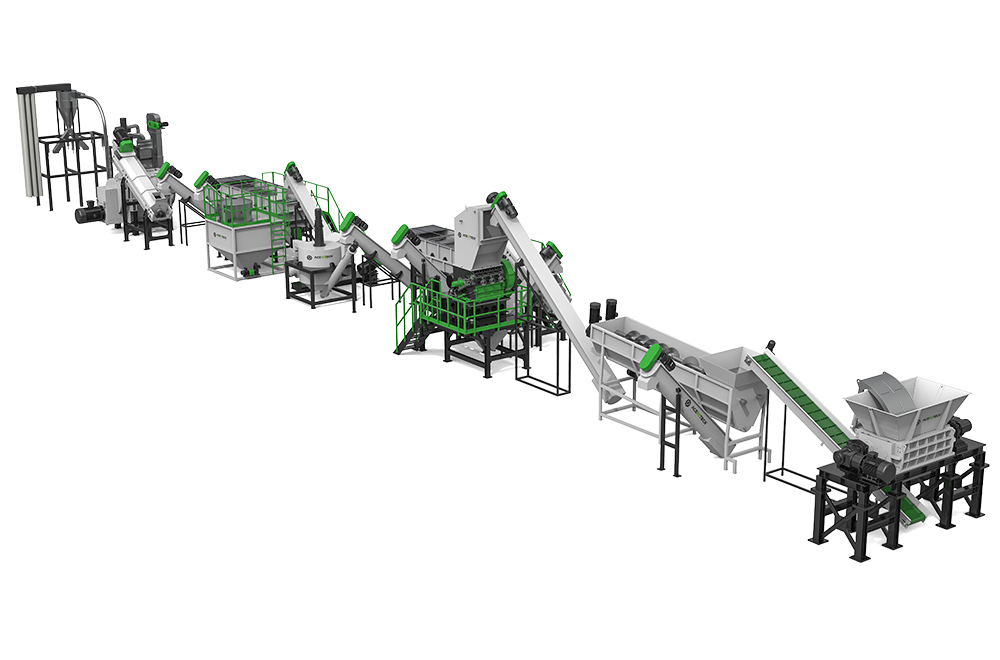

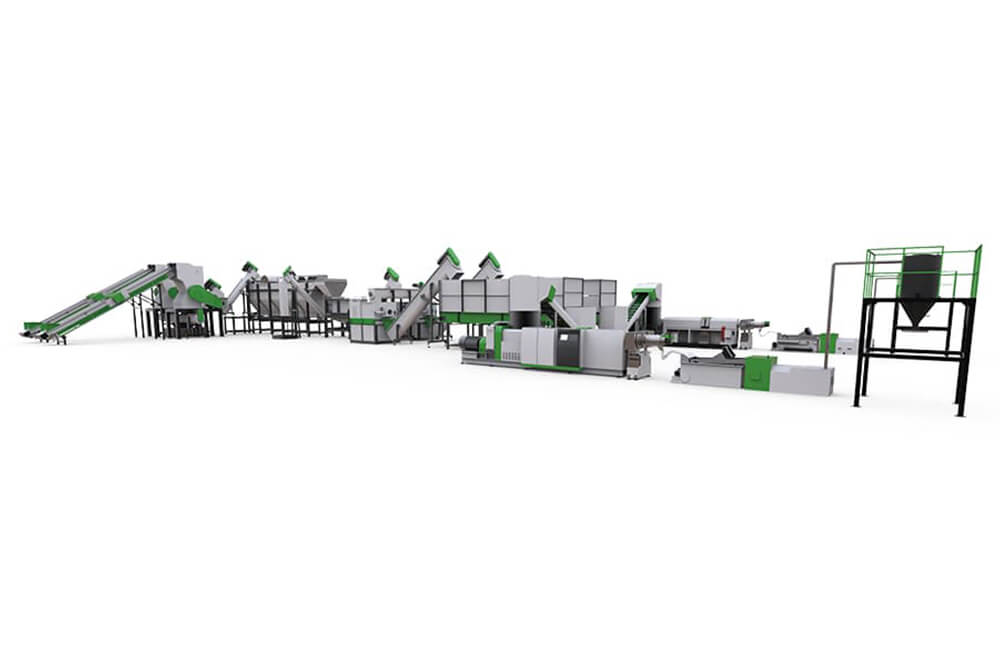

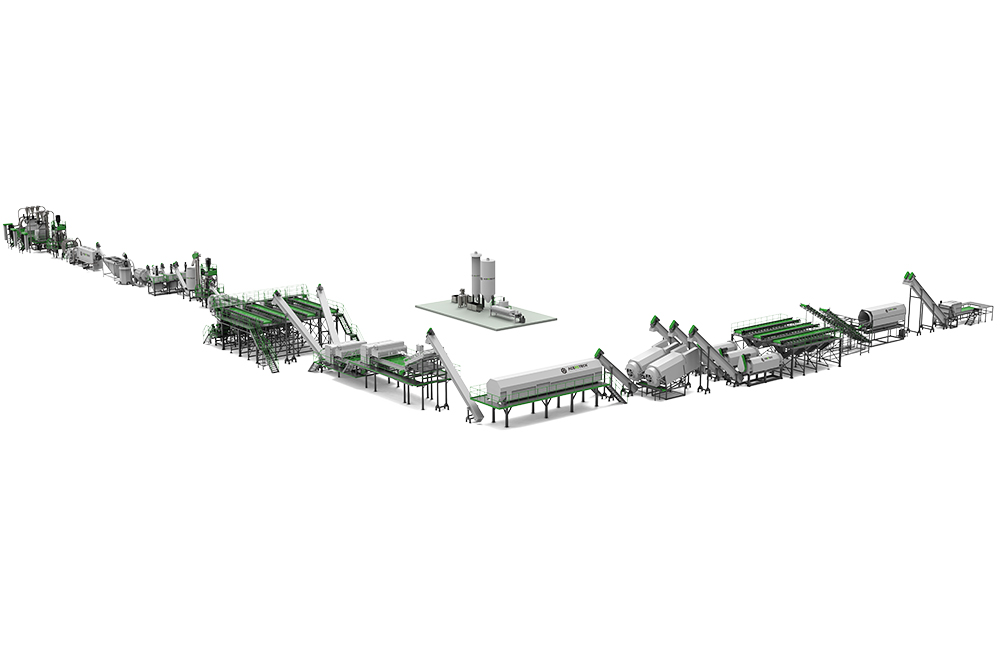

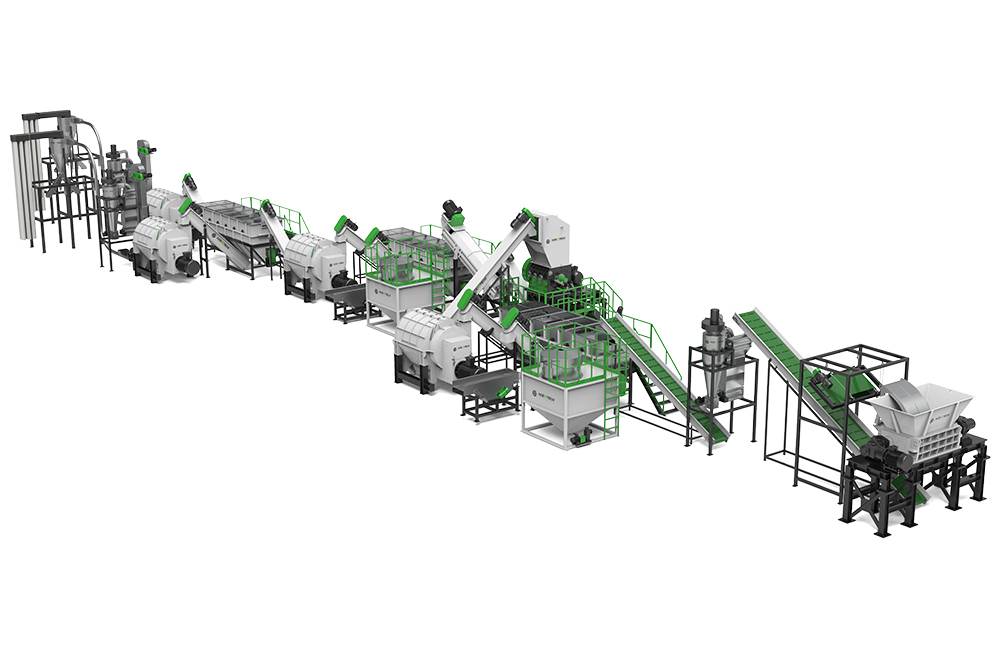

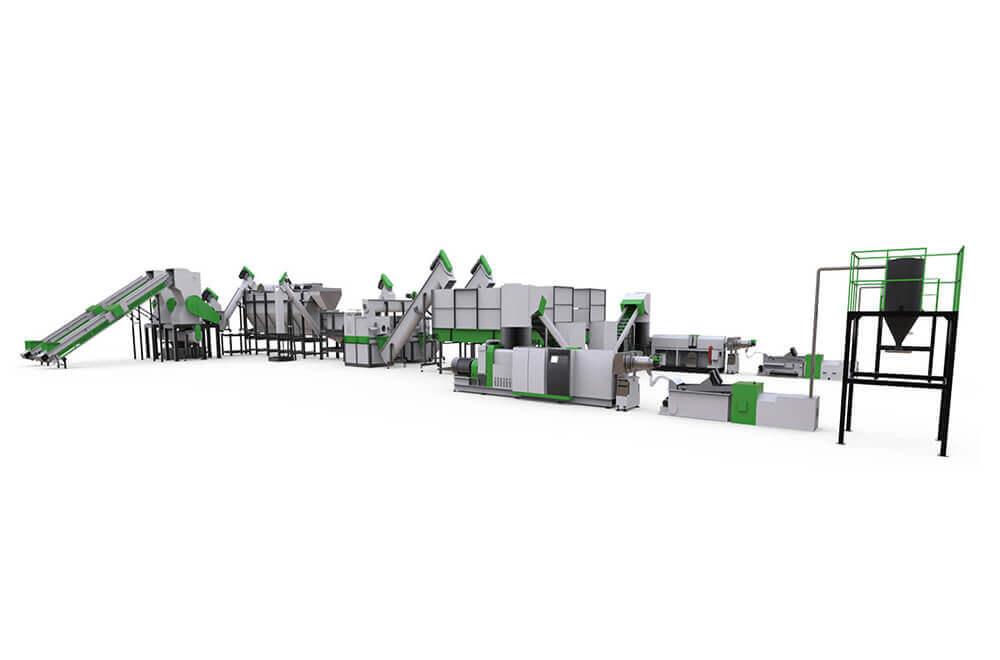

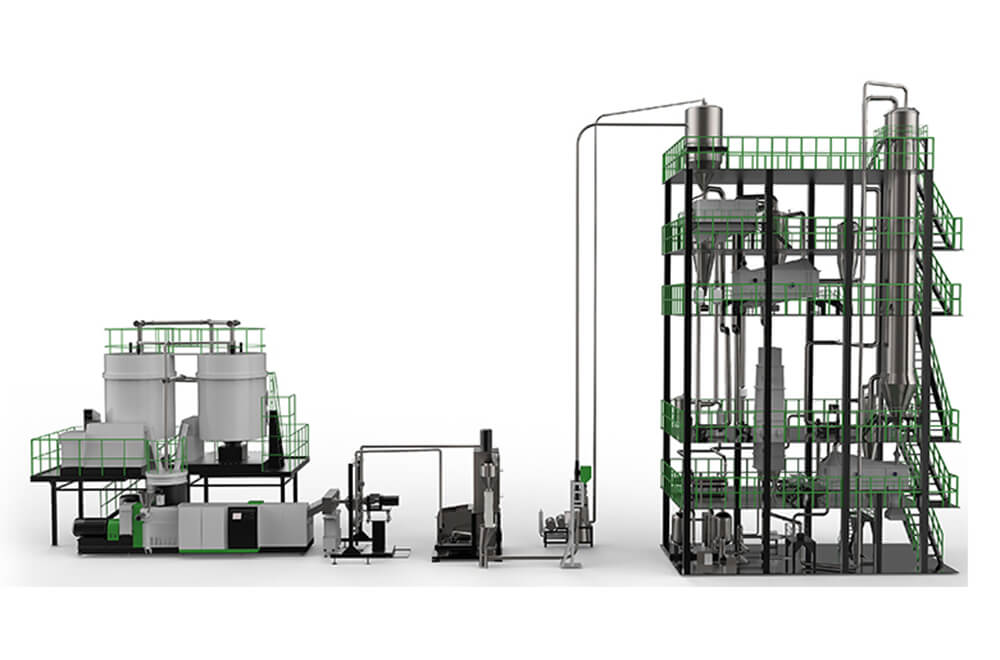

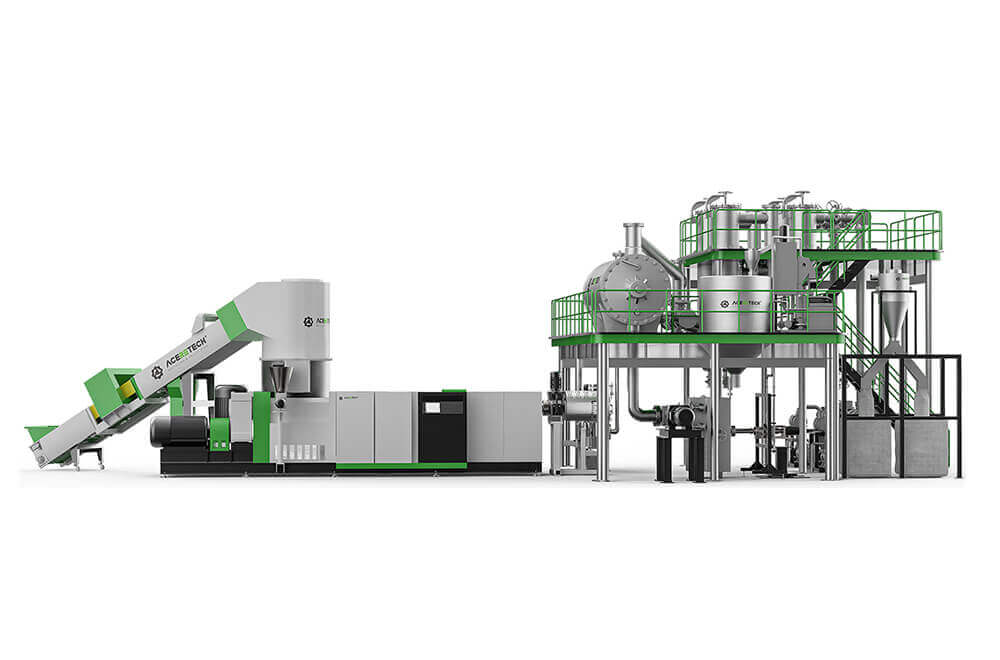

When producing films used in solar power modules, the production line will produce waste films and mold materials at the same time. To effectively save costs, the recommendation can refer to our ASP shredding and pelletizing system.

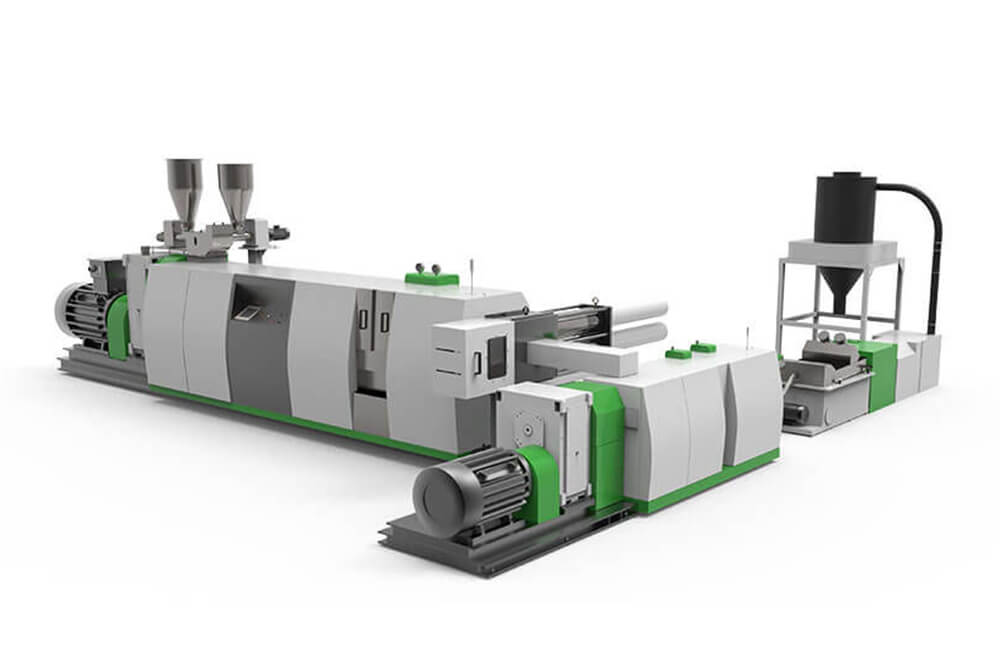

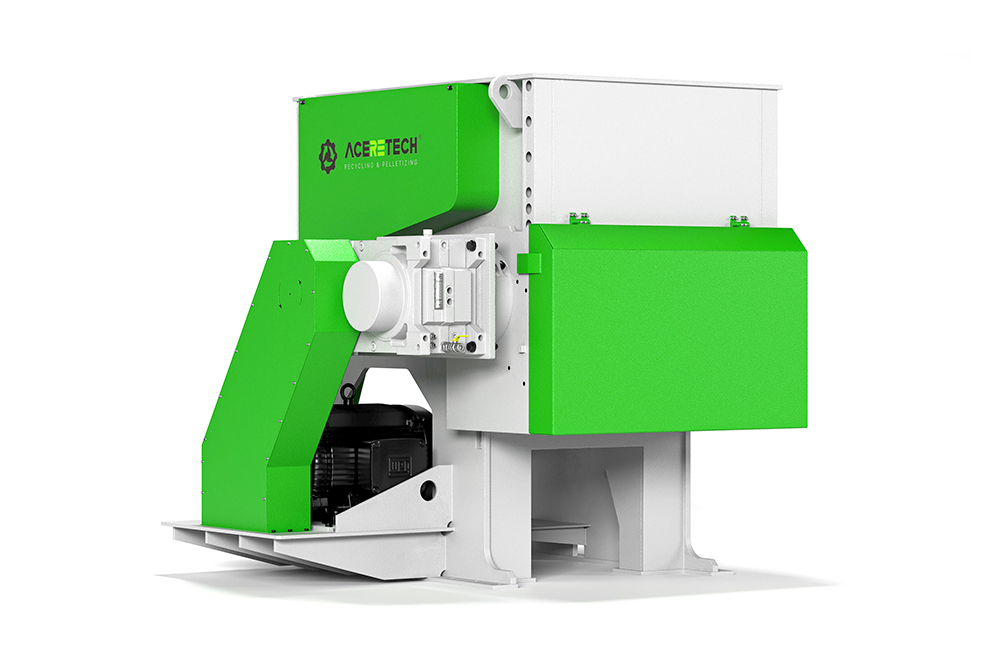

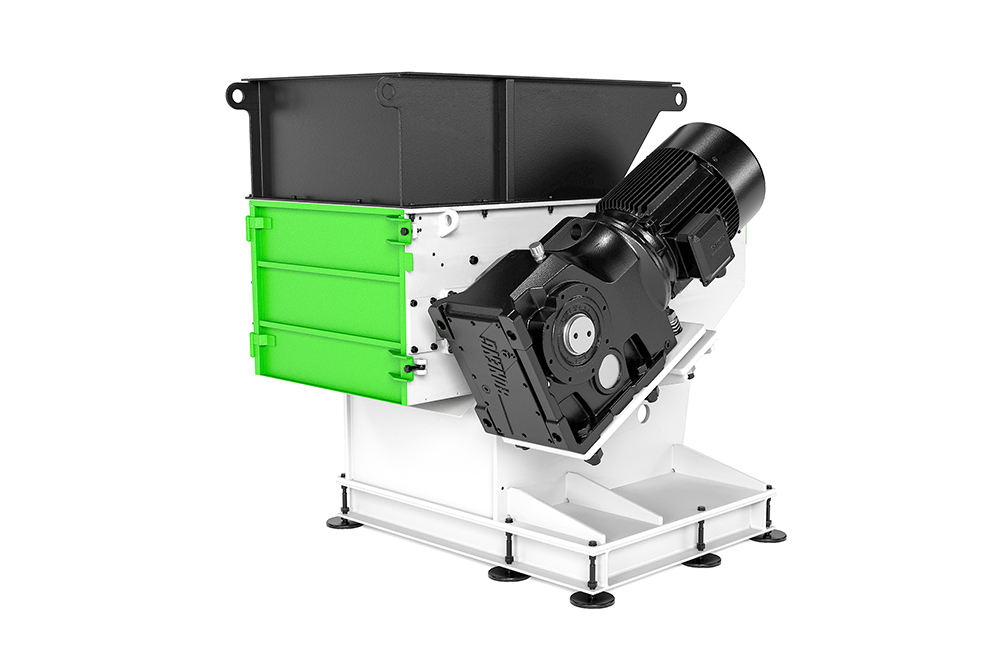

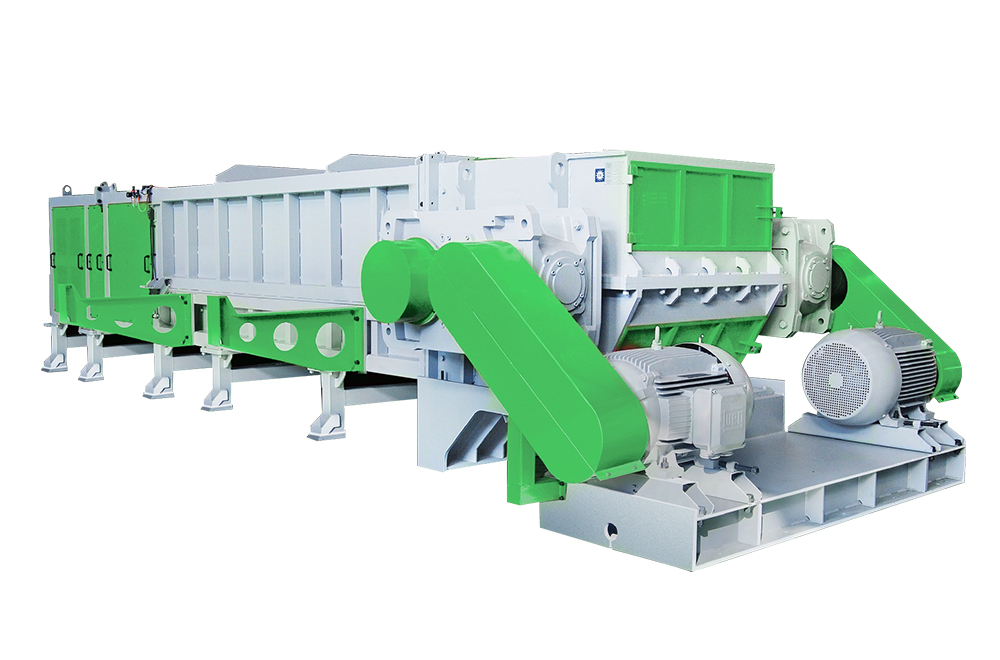

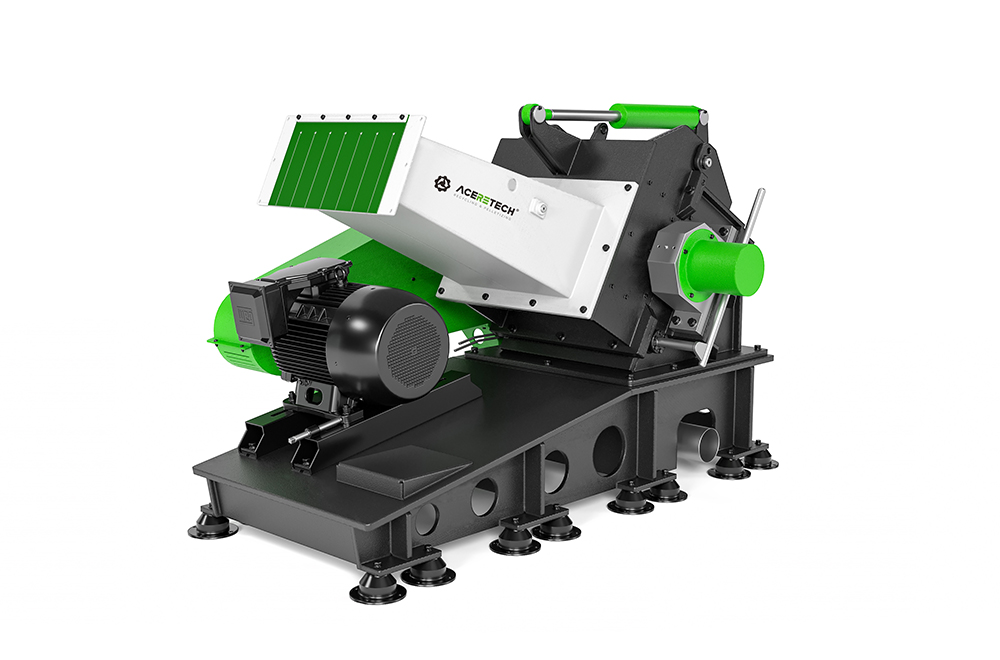

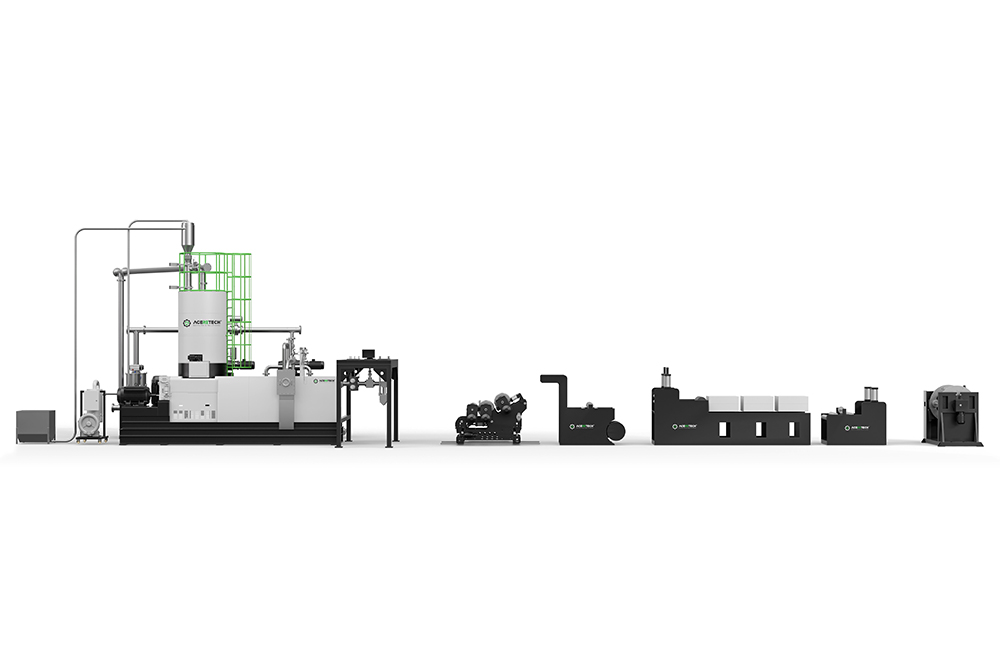

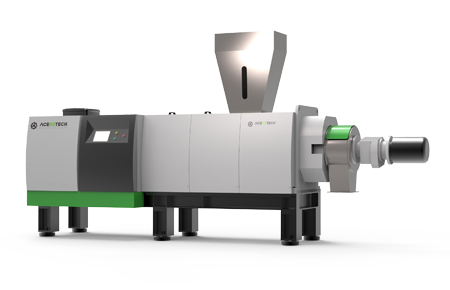

Our ASPTM series shredding and granulation system integrates shredding, crushing, forced feeding, plasticization, and granulation. Applied in the plastic recycling and pelletizing process, it is an integrated and cost-saving solution for various plastic waste materials, such as film, raffia, scraps, purge, hollow parts, bottles, and foam materials in a factory recycling.

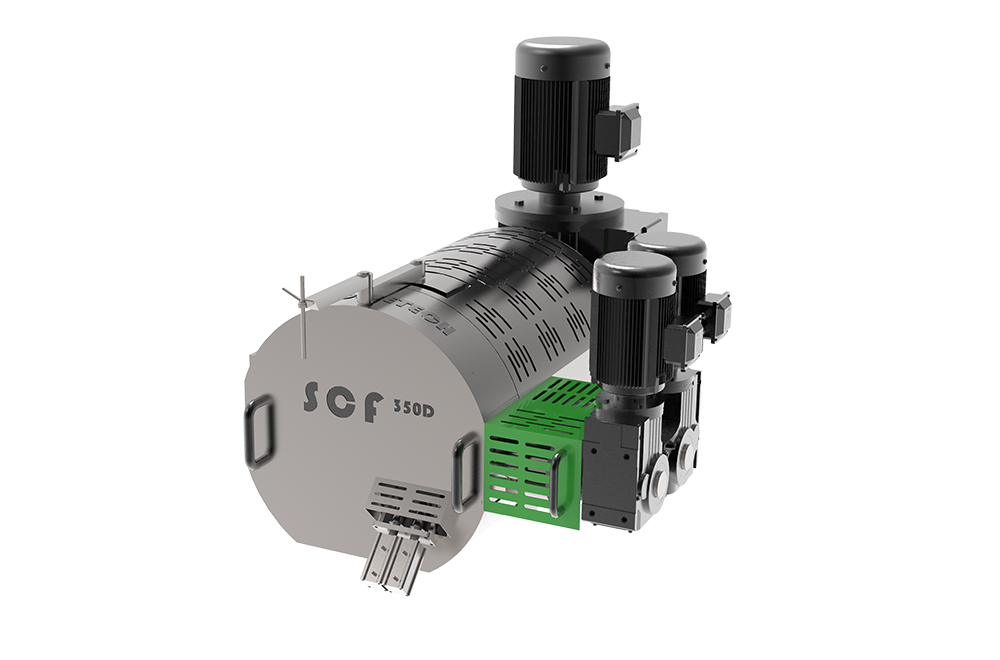

Die-face water ring pelletizing system set as the standard granulating method in ASPTM system. Self-adjusting pelletizing head for the best granulate quality and long using-life thanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure.

The recycled pellets can be applied in the downstream PVDF film production used for solar power generation, chemical properties of PVDF film are excellent in UV resistance, corrosion resistance, especially flame retardant.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us