Efficient Recycling Of PET

Ideally, recycled PET is first used for high-quality uses and then gradually used for low-quality uses. rPET has reached food-grade standards, enabling a high-quality "bottle-to-bottle" recycling model. However, according to ICIS statistics, 66% of the world's rPET recycled materials are currently used in the field of chemical fiber, which belongs to "downgrade recycling".

In practical applications, many consumer brand enterprises require the proportion of recycled materials to reach 30%, which can prolong the service life of PET. Some companies have done experiments and have been using 100% recycled materials. PET bottles can be recycled up to about 8 times. After that, the performance of the product decreased significantly, it became brittle, and the color turned yellow. Of course, some companies have proposed the use of 100% rPET, such as PepsiCo, Coca-Cola, etc. have proposed or launched 100% rPET beverage packaging bottles, which will pose considerable challenges to the quality and processing technology of recycled raw materials.

.jpg)

Regeneration starts with recycling. The quality of recycled PET bottles, whether they are contaminated or not, directly affects the application of rPET. As a result, many companies have focused on the construction of recycling systems and began to deploy them to eliminate pollution at the source.

Recycling starts with design. The design of the bottle largely determines the quality of rPET. For example, some bottles are film-coated all-inclusive bottles and cannot be sorted; there are many PVC labels, which are indistinguishable from PET, which directly affects the quality of rPET; some self-adhesive labels also contain adhesives that are difficult to clean.

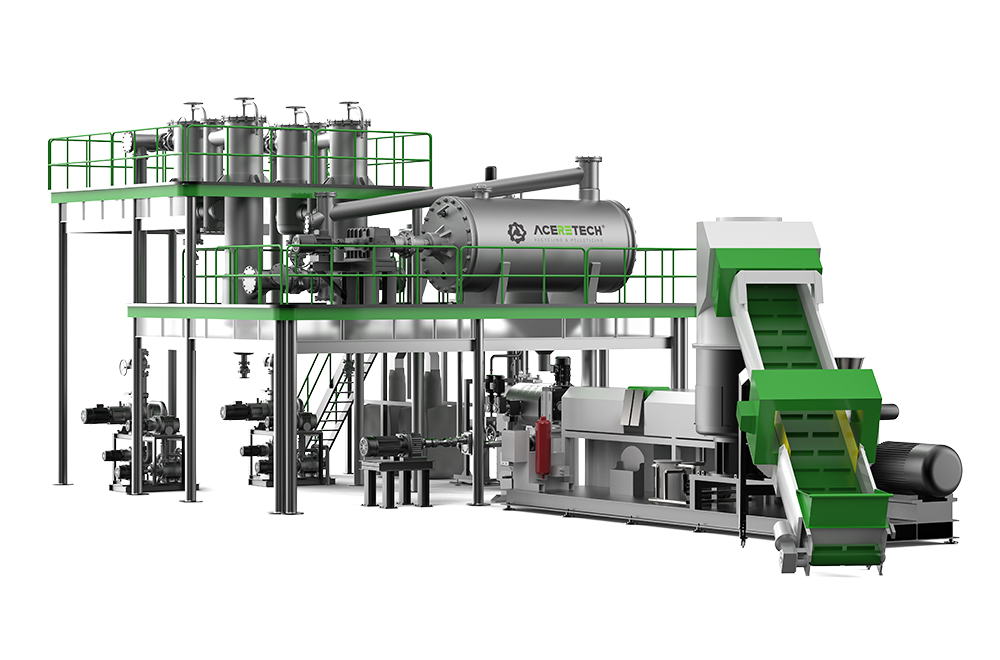

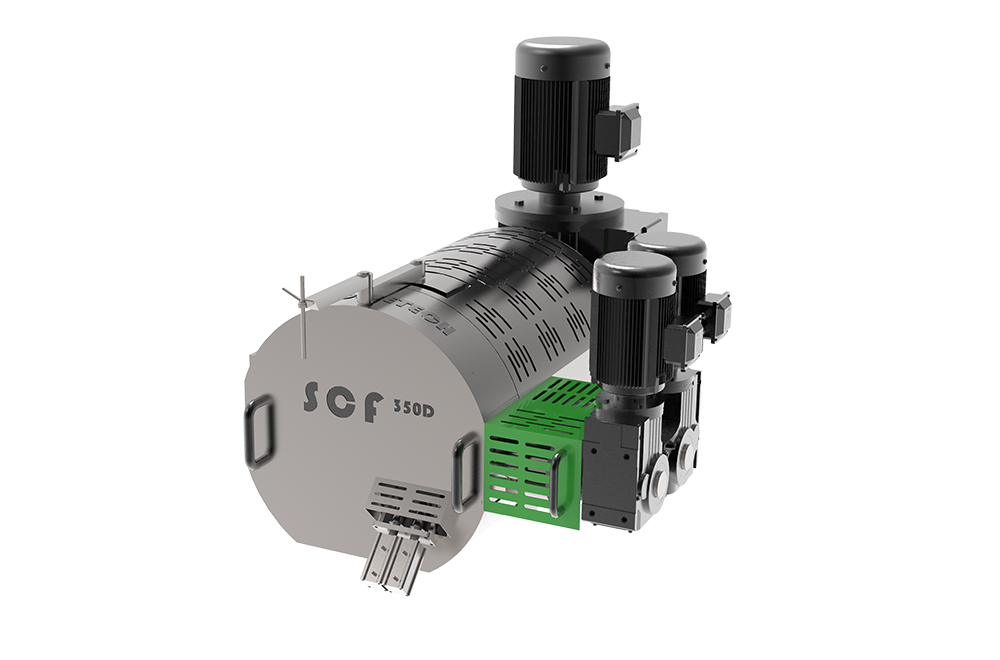

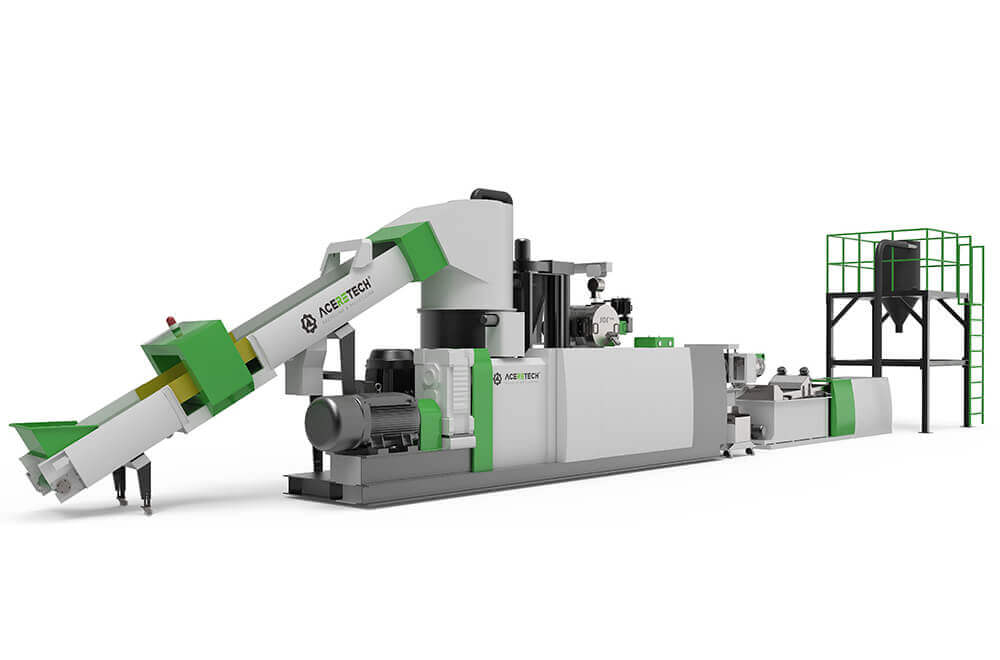

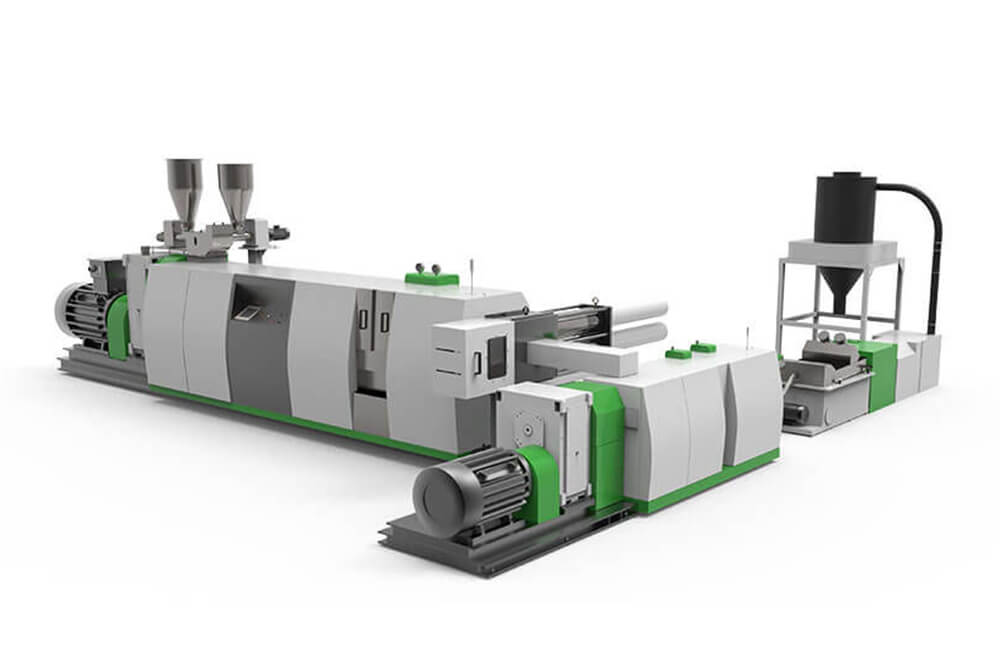

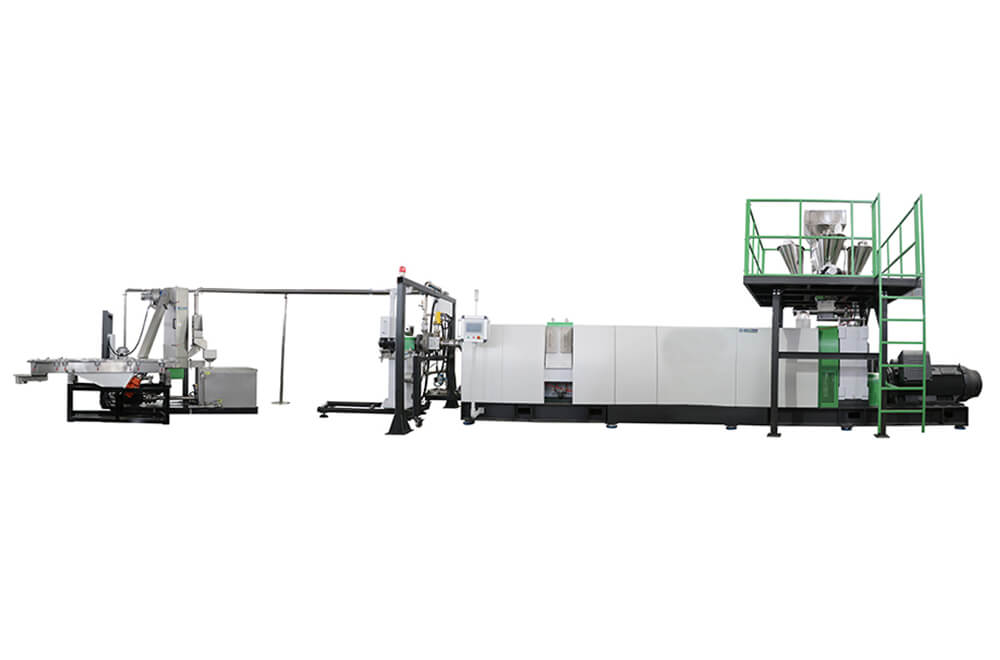

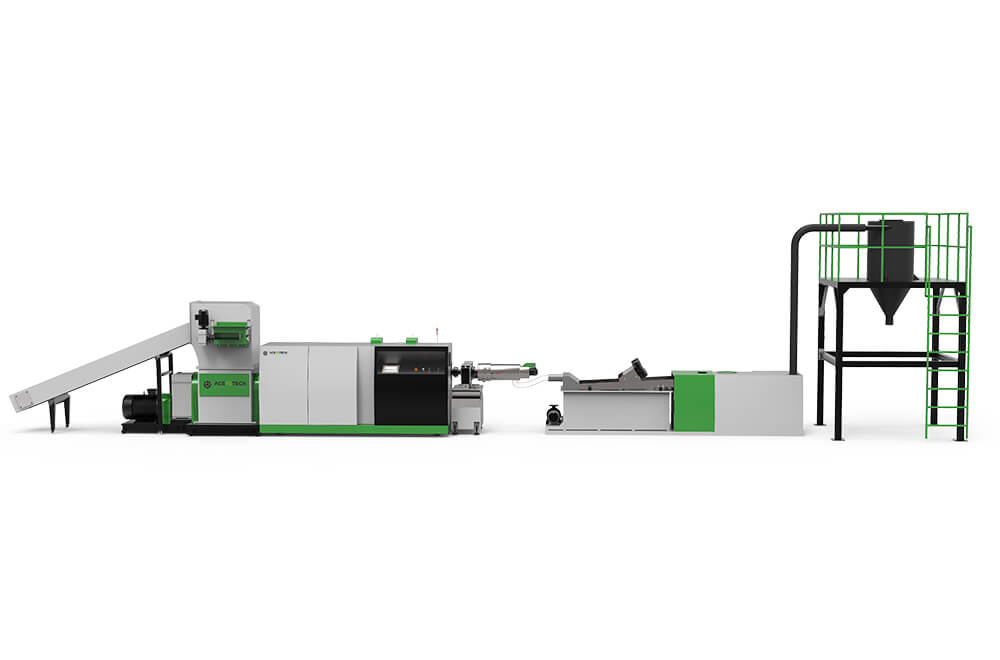

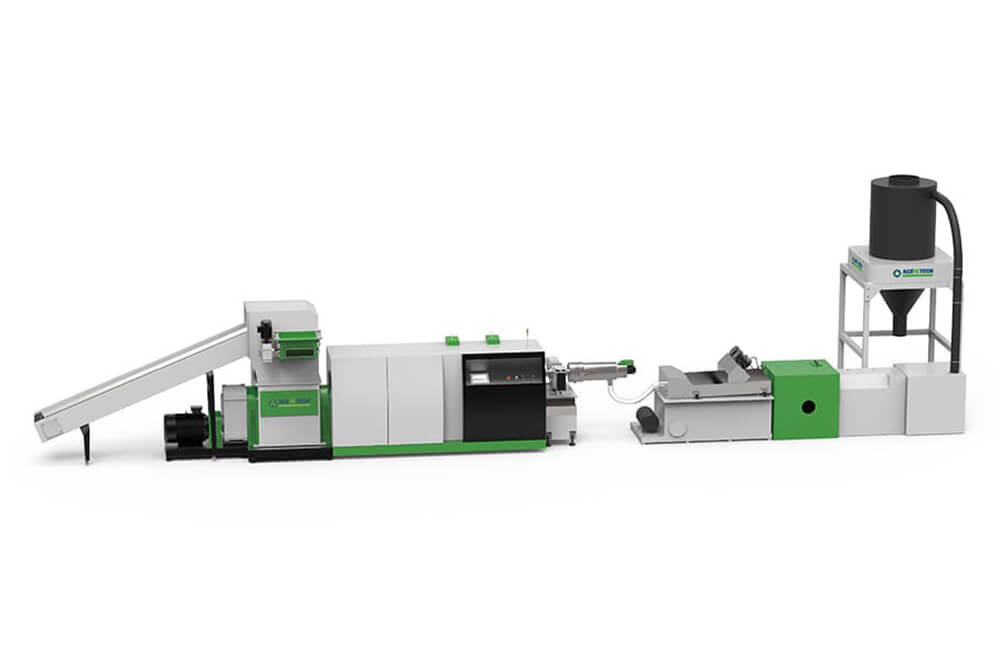

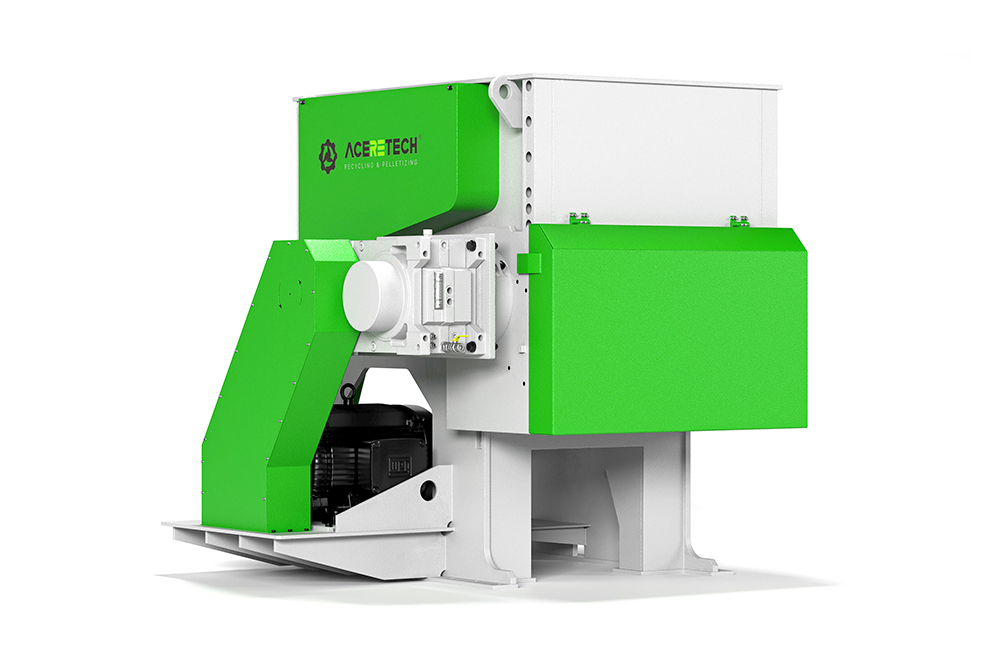

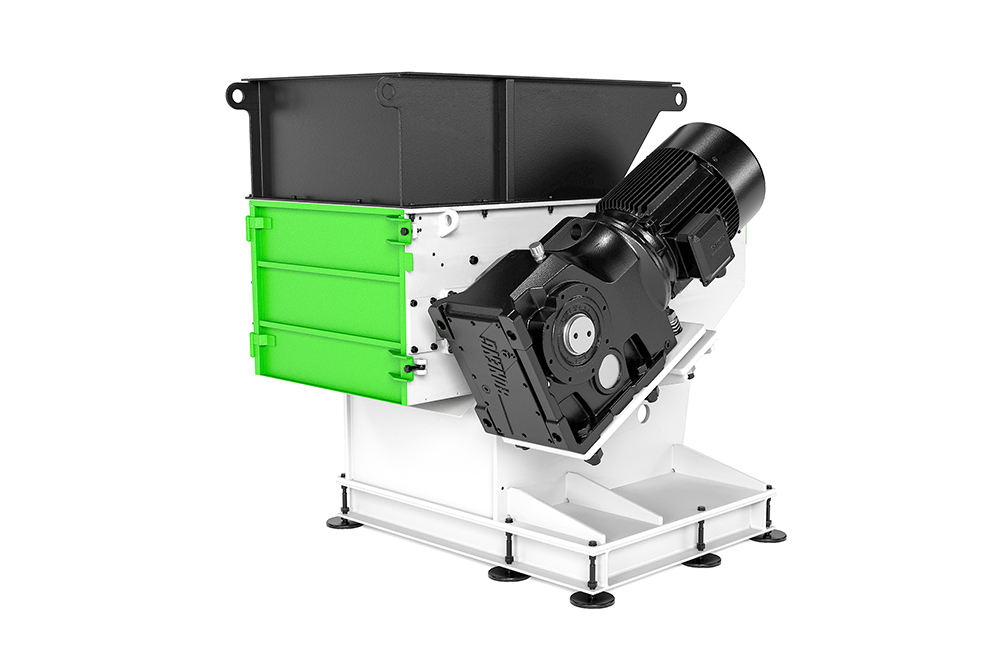

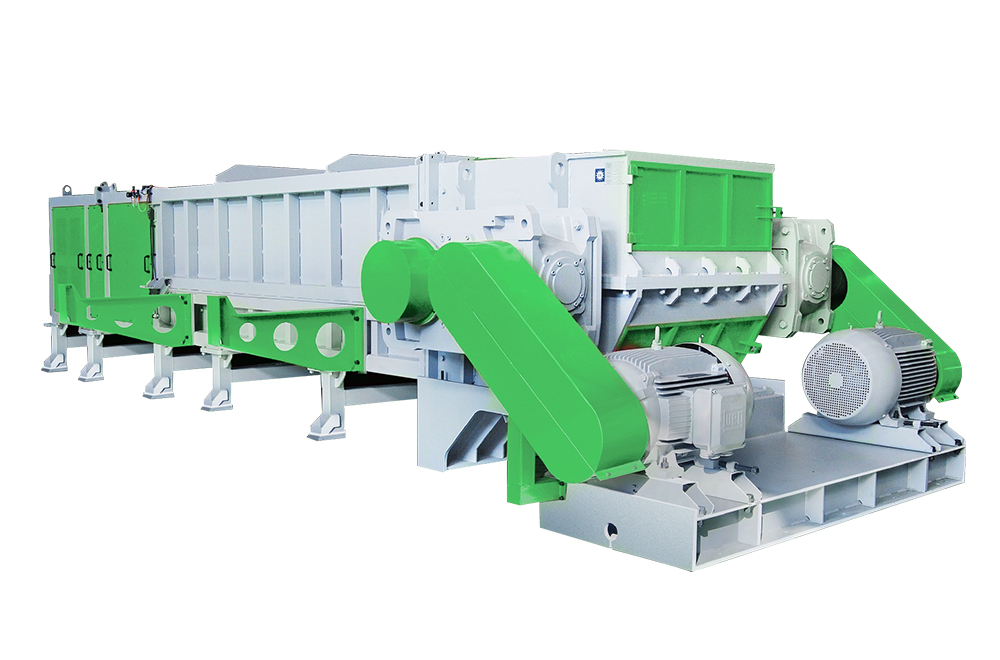

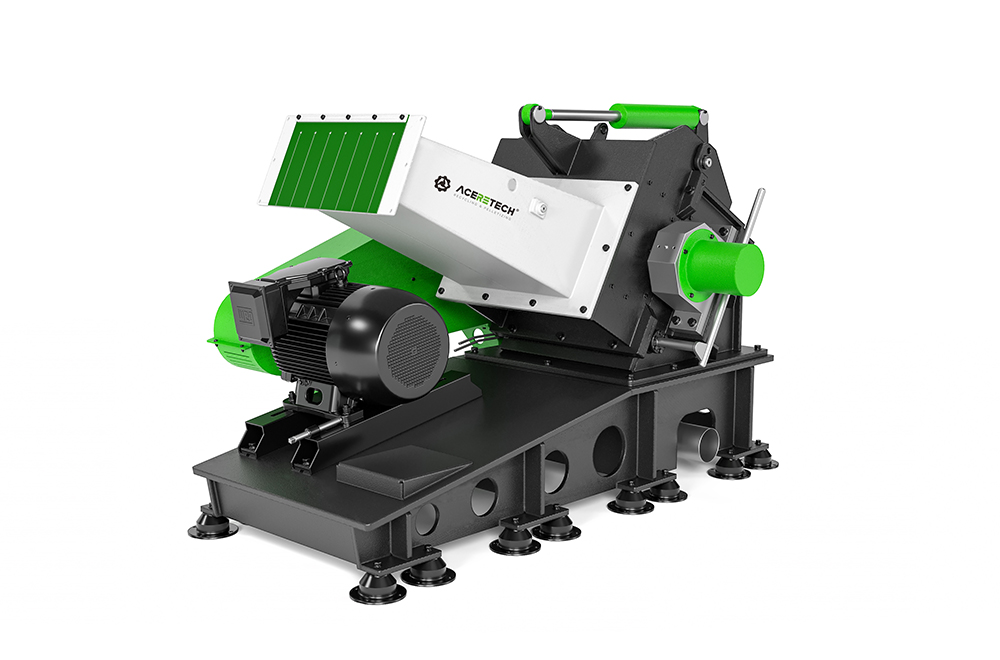

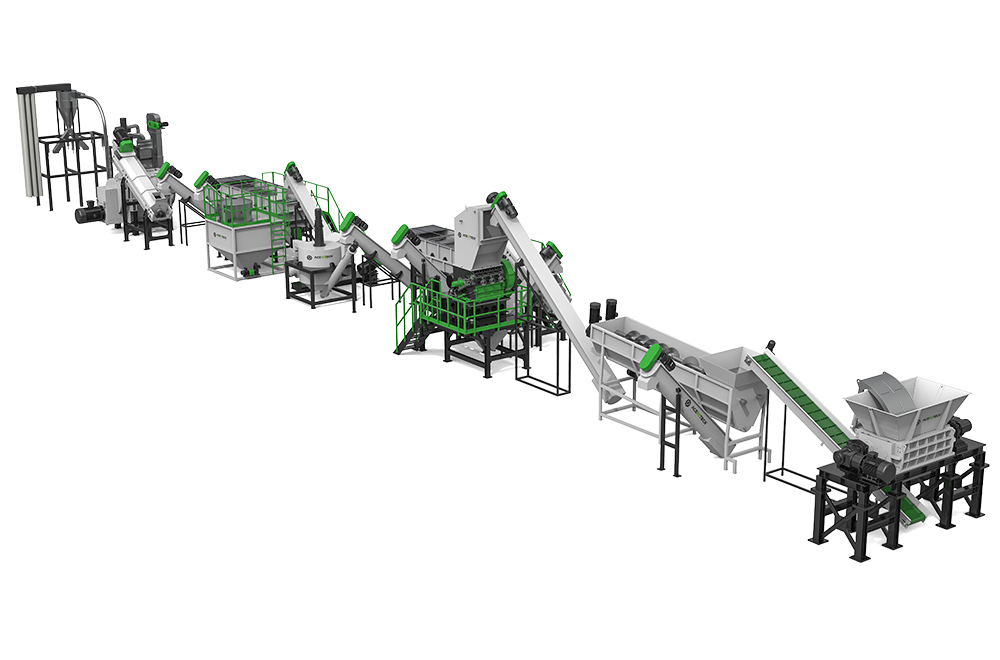

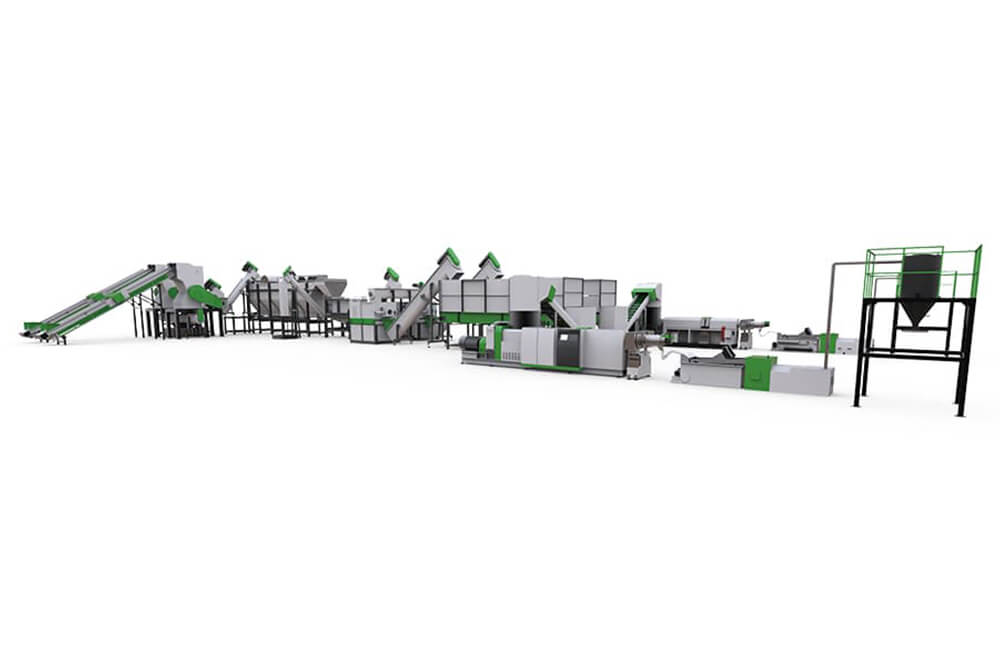

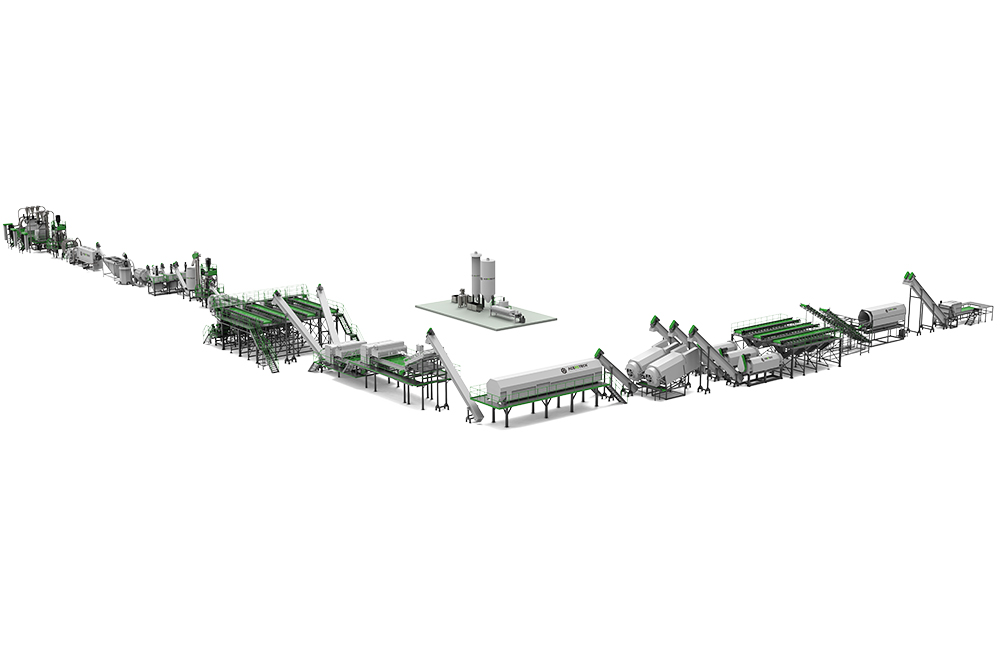

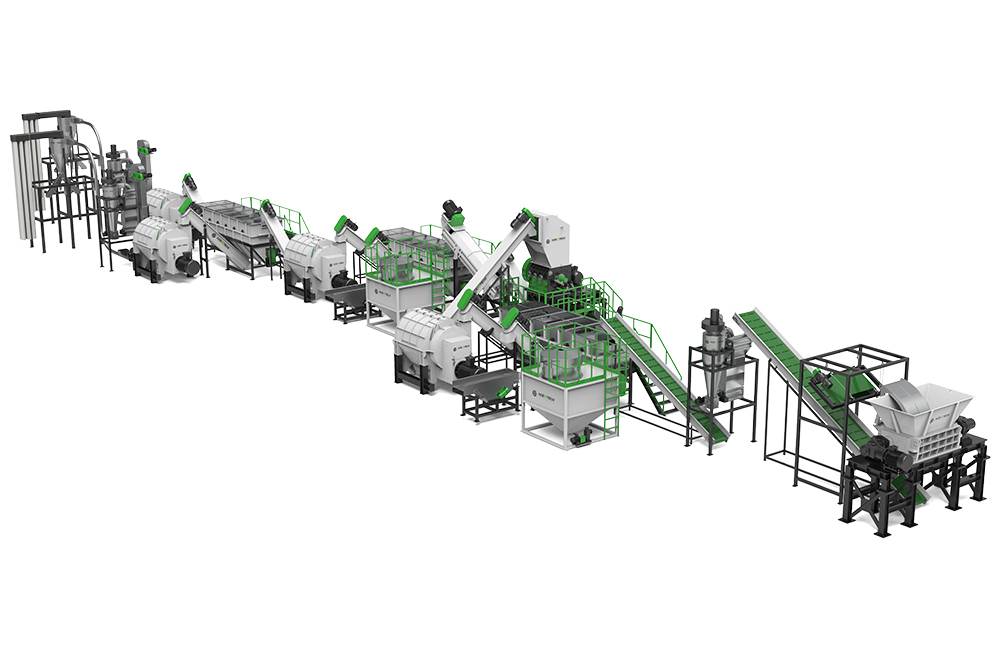

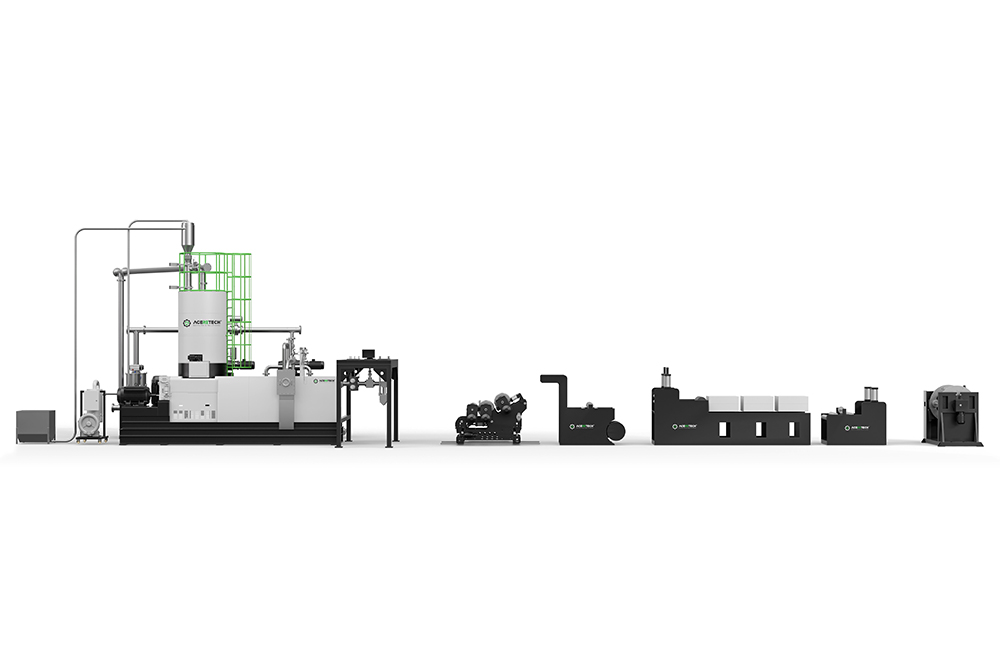

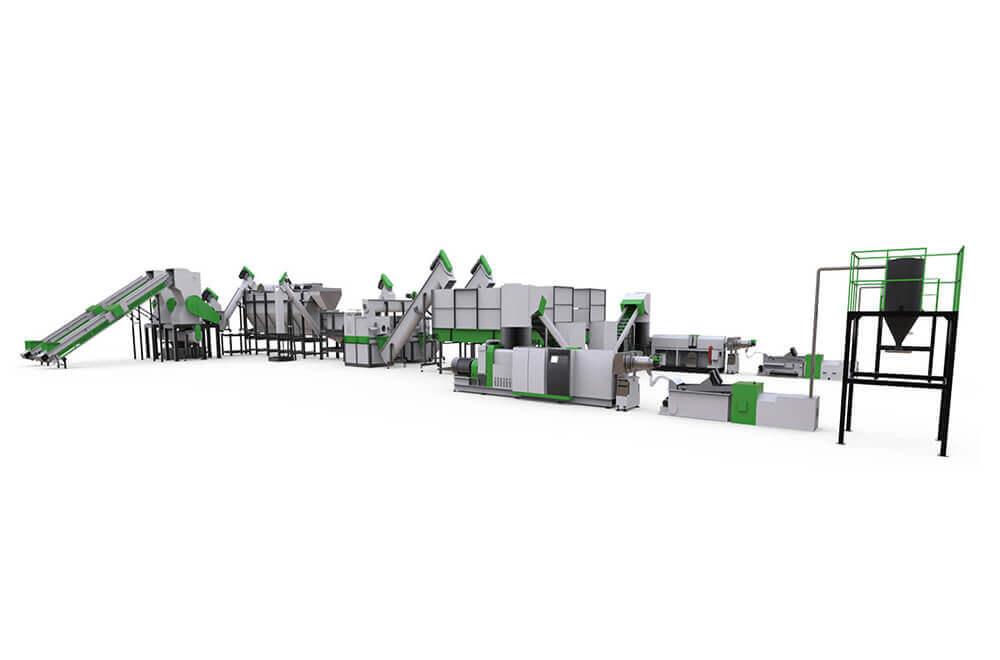

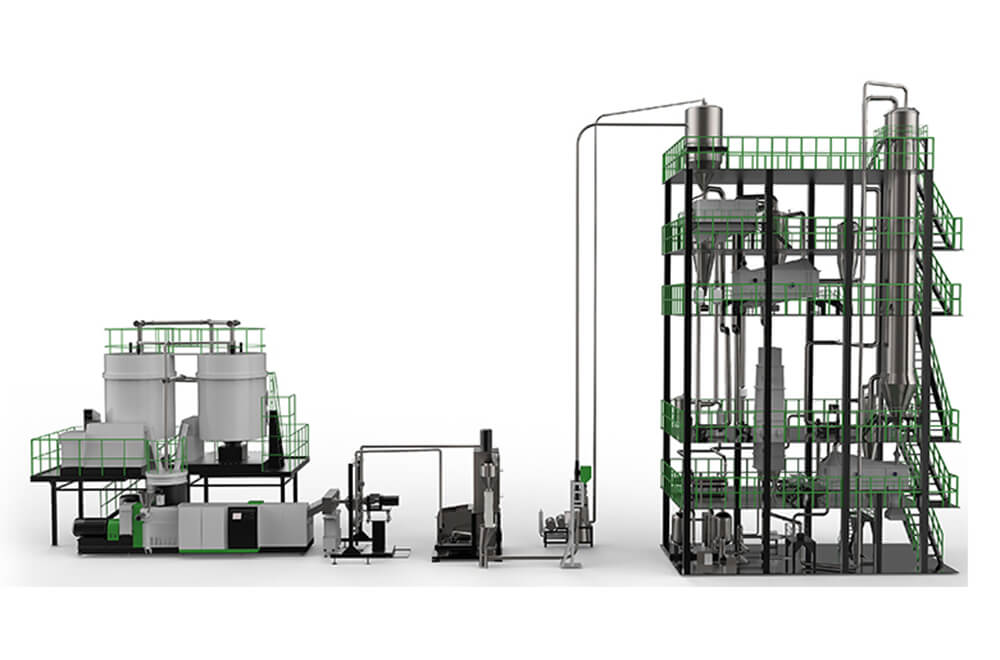

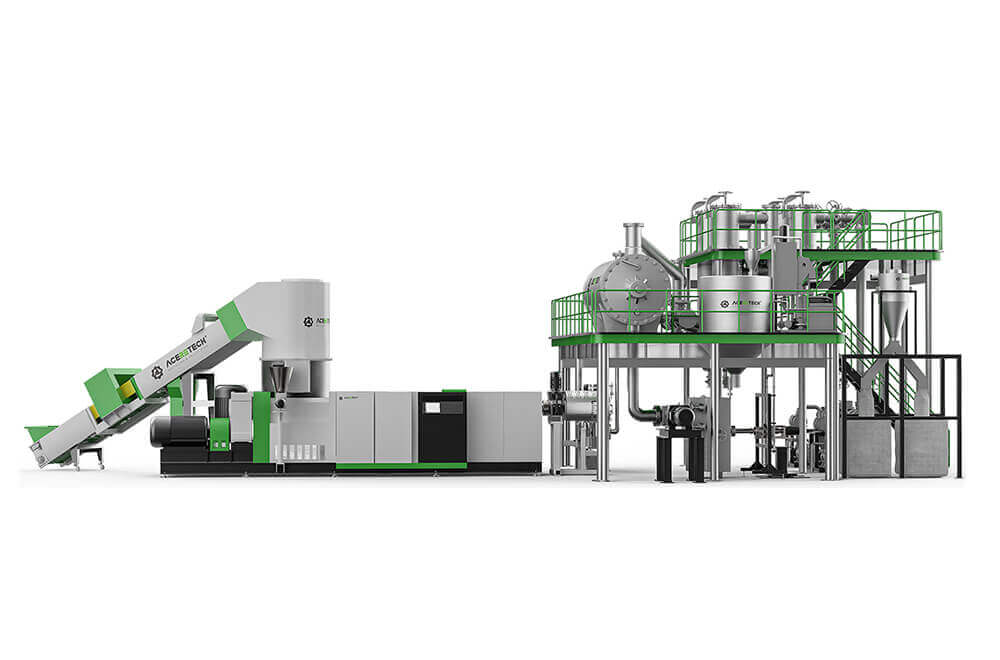

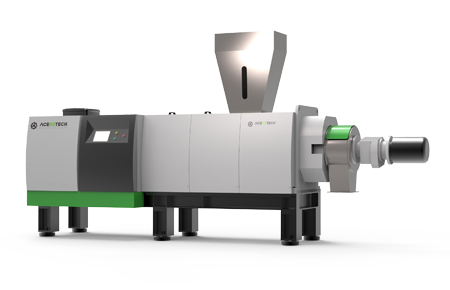

The PET Bottle To Bottle Recycling System developed by the ACERETECH team has the ability of a complete machine of turnkey projects. At present, there are at least 30 cases in the field of PET recycling around the world, including food-grade PET production lines. In addition, we also have the manufacturing capacity of a complete machine of PET non-woven fabrics, packing tapes, and sheet production lines, which can meet all the requirements of customers from recycling to regeneration.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us